A detailed design method of concrete prefabricated parts based on revit

A concrete prefabricated part, deepening design technology, applied in calculation, instrumentation, electrical digital data processing, etc., can solve problems such as the inability to realize family nesting design, the inability to add steel bar shape diagrams, and affect the design efficiency of concrete prefabricated parts. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with specific embodiment and accompanying drawing, a kind of concrete prefabricated part deepening design method based on Revit of the present invention is described in detail:

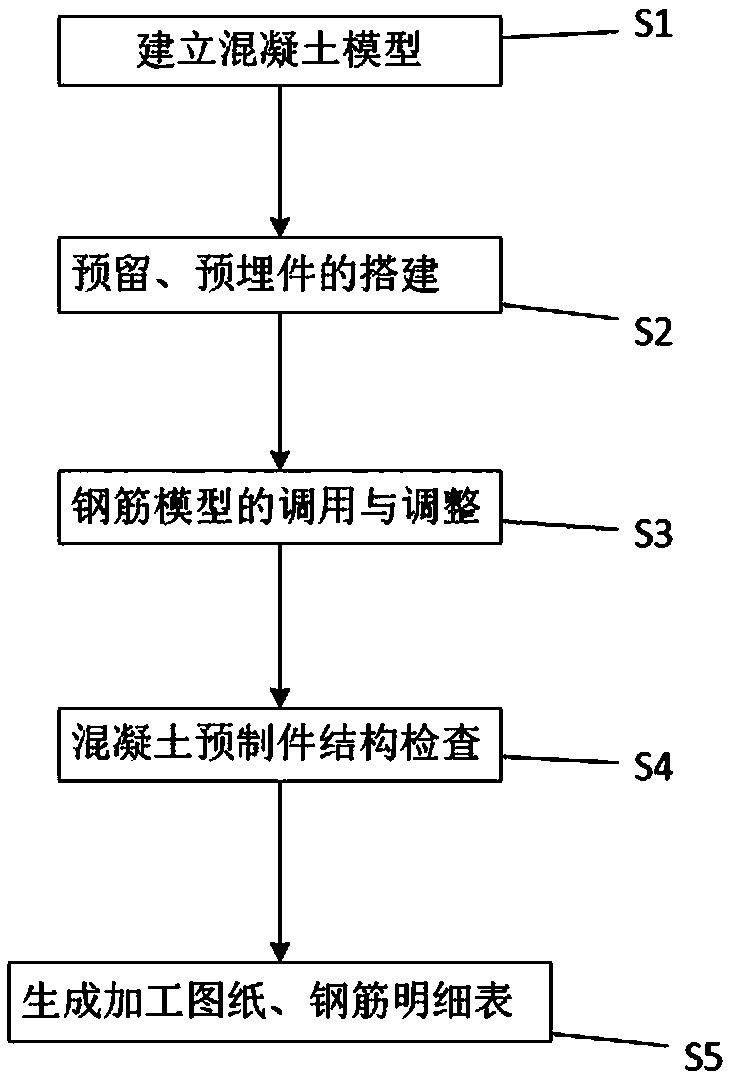

[0038] figure 1 An operation flow chart of a detailed design method for concrete prefabricated parts based on Revit is shown. It includes the following steps:

[0039] S1: Building a concrete model

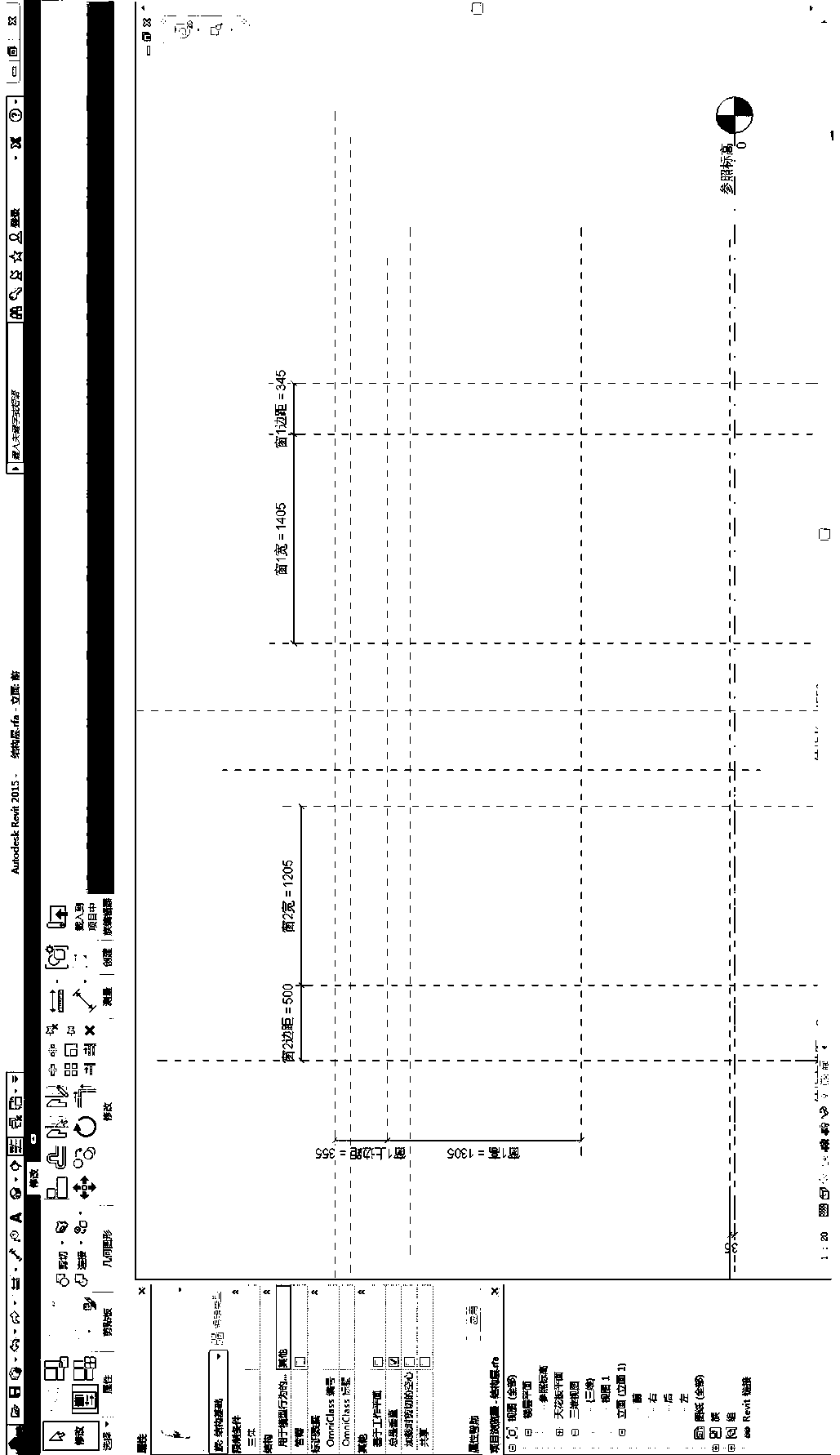

[0040] The specific operation in the Revit software is as follows: First, select the "Front Elevation View", click the "Reference Plane" option in the "Create" tab, and draw the reference plane, such as figure 2 As shown, it is the positioning plane of the contour of the concrete member; then, use the "Measurement" tool to dimension the "Reference Plane", such as image 3 as shown; then, click the "Create" tab "Stretch" option to enter the "Create Stretch" operation interface, as shown in Figure 4 As shown; Then, in the "Create Extrusion" operation interface, draw the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com