Welding spot detection device and method for cylindrical battery cap

A cylindrical battery, solder joint detection technology, applied in character and pattern recognition, image data processing, instruments, etc., can solve problems such as incomplete matching of quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

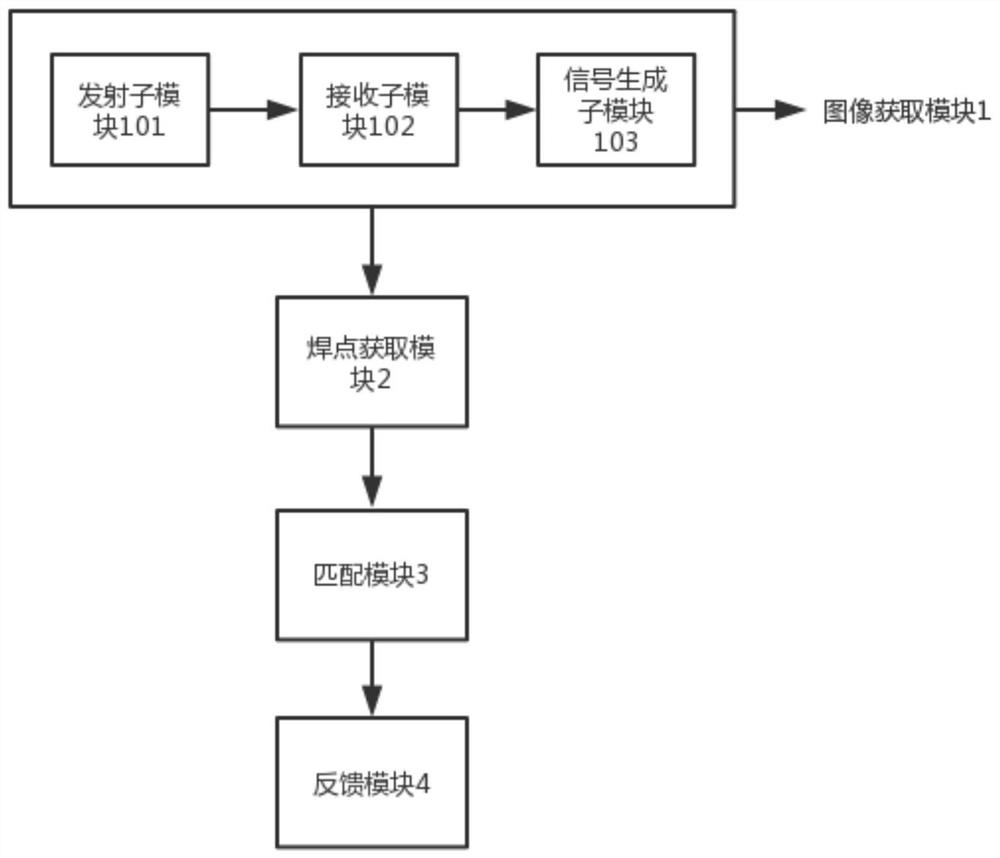

[0079] Such as figure 1 As shown, the present invention provides a welding spot detection device for a cylindrical battery cap, comprising:

[0080] Image acquisition module 1, used to acquire the solder joint image of the cylindrical battery cap;

[0081] The solder joint acquisition module 2 is used to detect the solder joints in the solder joint image based on the multi-feature solder joint template to obtain solder joint information;

[0082] The matching module 3 is used to match the solder joint information with the solder joint standard information of the standard solder joint template corresponding to the actual production drawing, and when it does not match, the corresponding result is sent to the feedback module 4;

[0083] The feedback module 4 is configured to feed back the result to the user terminal.

[0084] In this embodiment, the solder joint image is an image obtained with solder joint information; the multi-feature solder joint template is a template compo...

Embodiment 2

[0087] On the basis of Embodiment 1, the image acquisition module 1 includes:

[0088] The emitting sub-module 101 is used to emit test light to the cylindrical battery cap from multiple directions;

[0089] The receiving sub-module 102 is configured to receive the feedback light generated after the test light emitted by the transmitting sub-module 101 contacts the cylindrical battery cap;

[0090] The information generation sub-module 103 is configured to generate a corresponding point signal based on the feedback light, and amplify the obtained electrical signal to obtain an amplified electrical signal, and generate an image of the cap of the cylindrical battery according to the amplified electrical signal;

[0091] Based on the test light in each direction, the image information in all directions of the cylindrical battery cap is obtained, and the obtained image information is fused to obtain a complete 3D image of the cylindrical battery cap.

[0092] In this embodiment, ...

Embodiment 3

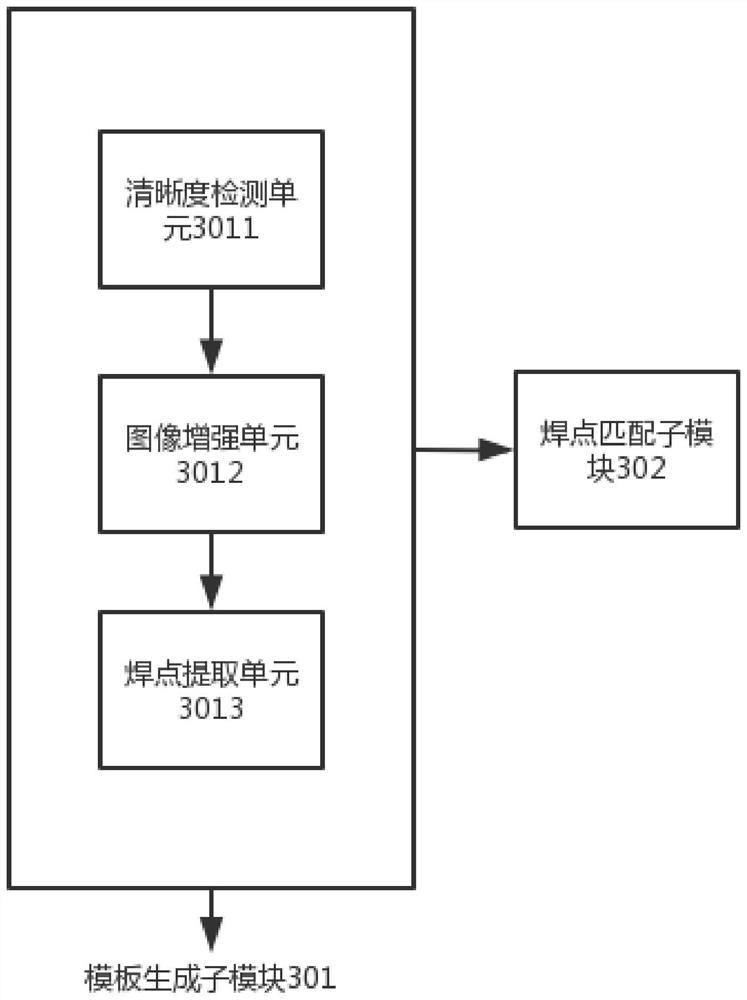

[0095] Based on the basis of embodiment 1, such as figure 2 As shown, the welding spot acquisition module 2 includes:

[0096] Solder joint positioning sub-module 201 is used to obtain all solder joint appearance information of solder joints in qualified and unqualified states according to historical actual production drawings, classify based on appearance features, and obtain various types of appearance features of solder joints, based on the appearance Features, generate multi-feature solder joint templates;

[0097] Based on the appearance of solder joints in the multi-feature solder joint template, extract feature points similar to the appearance of solder joints in the multi-feature solder joint template in the 3D complete image, set the extracted feature points as the first feature point to be processed, and obtain all According to the position information of the first feature point to be processed in the cylindrical battery cap, the image information corresponding to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com