Special-shaped copper bar for hydroelectric generator and its processing technology and application

A hydroelectric generator and special-shaped technology, applied in circuits, electrical components, electromechanical devices, etc., can solve the problems of complex processing methods, increased labor time, and low yield, saving labor time, reducing size, and reducing production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

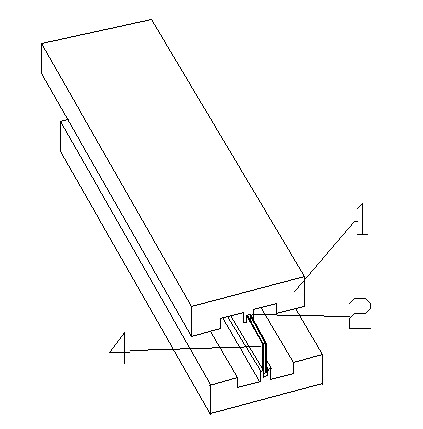

[0023] The special-shaped copper row 1 processing technology for hydraulic generator of the present invention comprises the following steps:

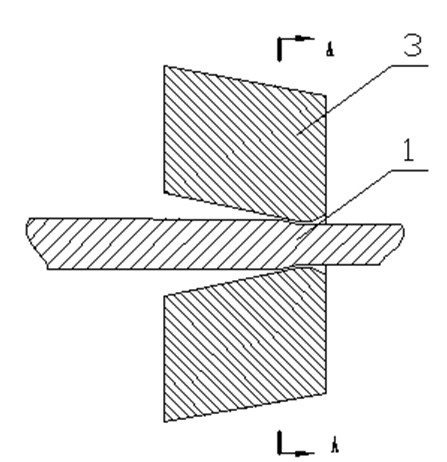

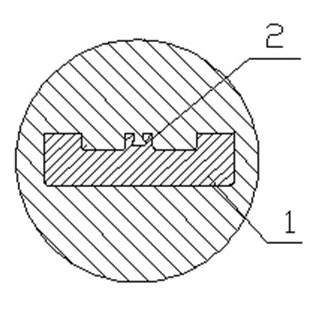

[0024] (1) According to the size and size requirements of the generator capacity, design the shape of the required special-shaped copper bar 1. The cross section of the copper bar 1 is "E" type. "Concave" type with rounded corners.

[0025] (2) Add electrolytic copper to the upper induction furnace for smelting, and add Ag and Bi to it, and adjust their content within their respective weight percentage ranges, Ag: 0.086%, Cu + Ag: 99.90%, and the rest is Bi: 0.0001%, Si: 0.0008%, Fe: 0.001% and other impurities. Melting temperature: 1200°C, smelting the required copper rod;

[0026] (3) Extrude the Φ20 copper rod on the continuous extrusion machine to produce a metal rod slightly larger than the required profile copper bar 1. The finished product size is 43.2*12.25mm and the extruded size is 45*14.85mm. The tensile strength after ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com