Workpiece clamping structure for grinding tool, and tracking type casting edging machine and method

A technology of workpiece clamping and grinding tools, which is applied in the direction of machine tools suitable for grinding workpiece edges, grinding workpiece supports, and grinding machine parts, etc. It can solve problems such as harsh working environment, complicated operation, and inability to adapt to small batch production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below with reference to the embodiments of the present invention.

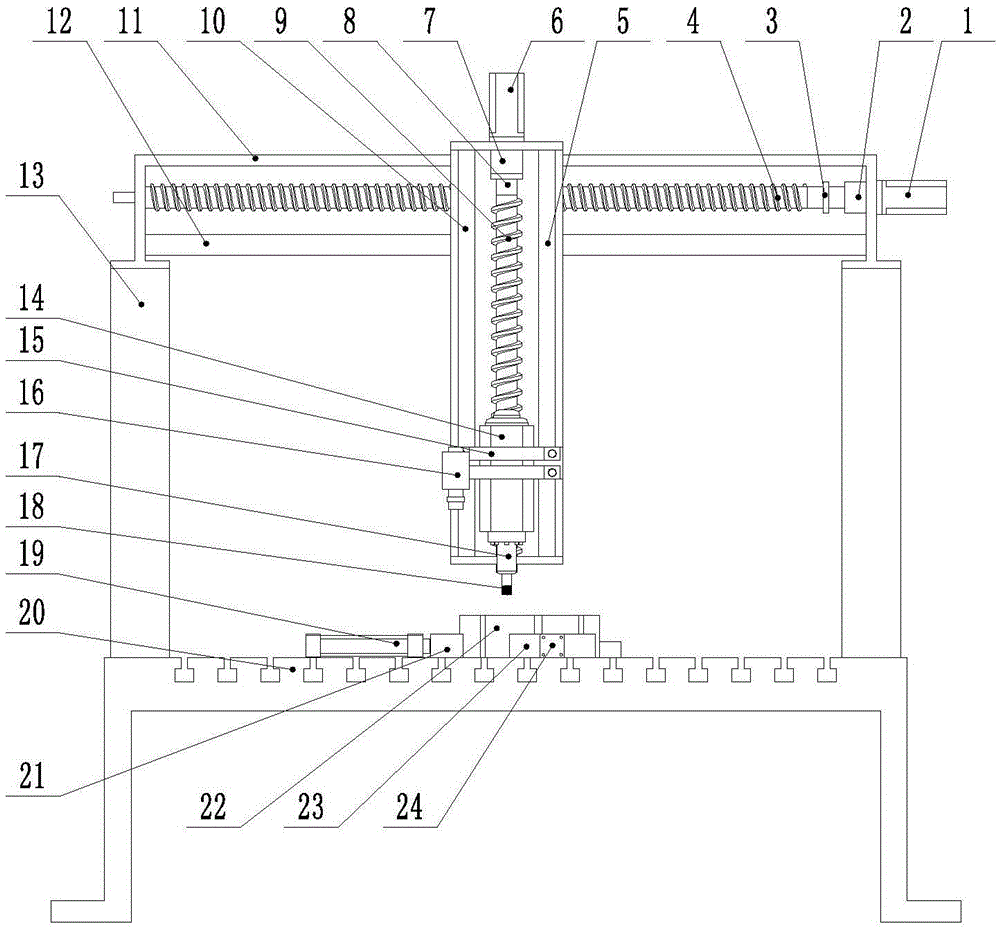

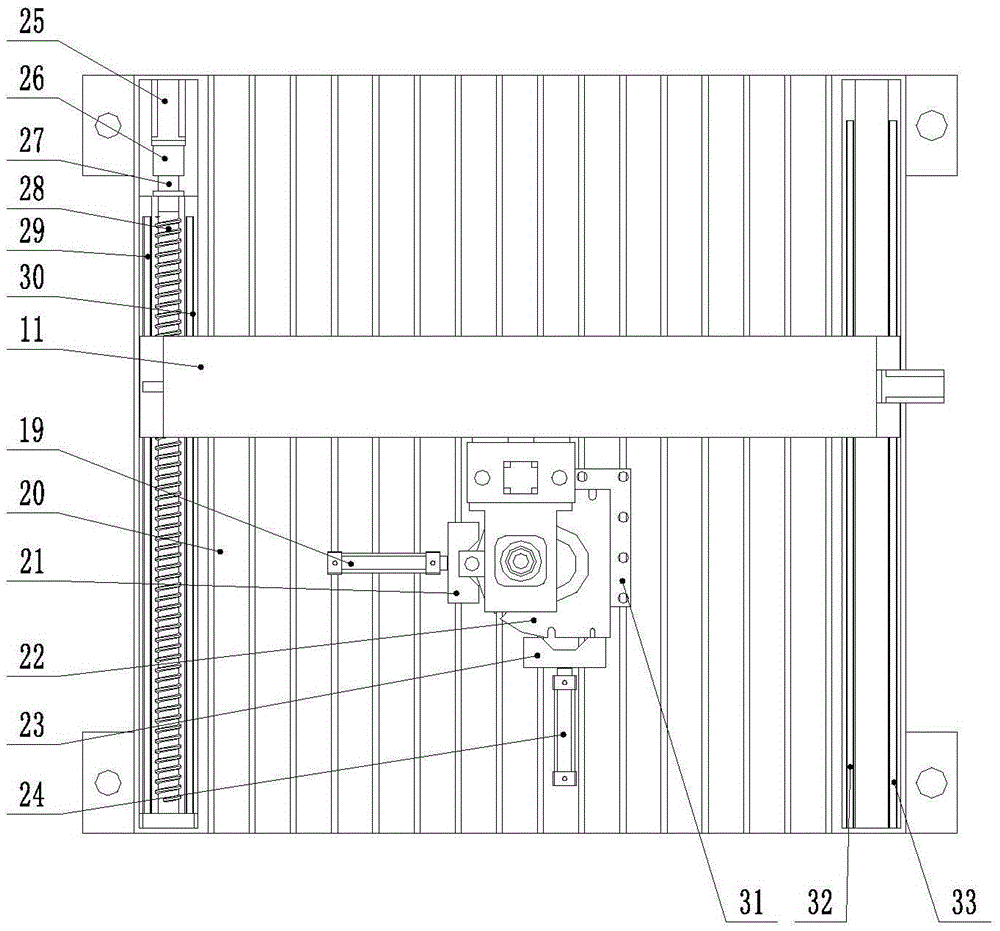

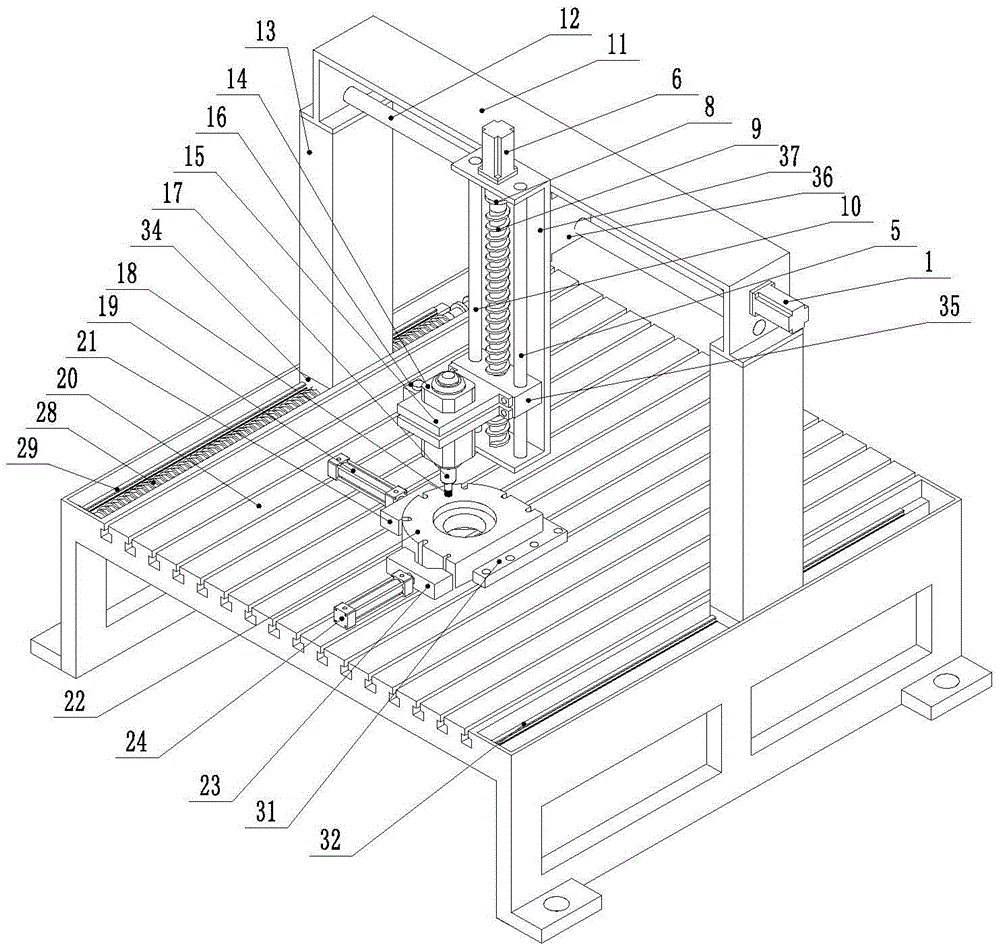

[0050] like Figure 1-3 As shown, a tracking type casting edging machine of the present invention includes an X-axis motor 1, an X-axis reducer 2, an X-axis coupling 3, an X-axis screw 4, a Z-axis right guide column 5, and a Z-axis motor 6. Z-axis reducer 7, Z-axis coupling 8, Z-axis screw 9, Z-axis left guide column 10, X-axis support 11, X-axis guide column 12, column 13, edging high-speed motor 14, Edging high-speed motor holder 15, industrial camera 16, grinding head quick change fixture 17, grinding head 18, X-direction cylinder 19, bed 20, X-direction clamping block 21, casting 22, edging groove 22-1, grinding Side outer circle 22-2, Y-direction clamping block 23, Y-direction cylinder 24, Y-axis motor 25, Y-axis reducer 26, Y-axis coupling 27, Y-axis screw 28, the first guide rail on the left side of the Y-axis 29. The second guide rail 30 on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com