Construction method of longspan deformed steel joist glass curtain wall

A construction method, glass curtain wall technology, applied to walls, building components, buildings, etc., to achieve the effects of high processing precision, simple operation, and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

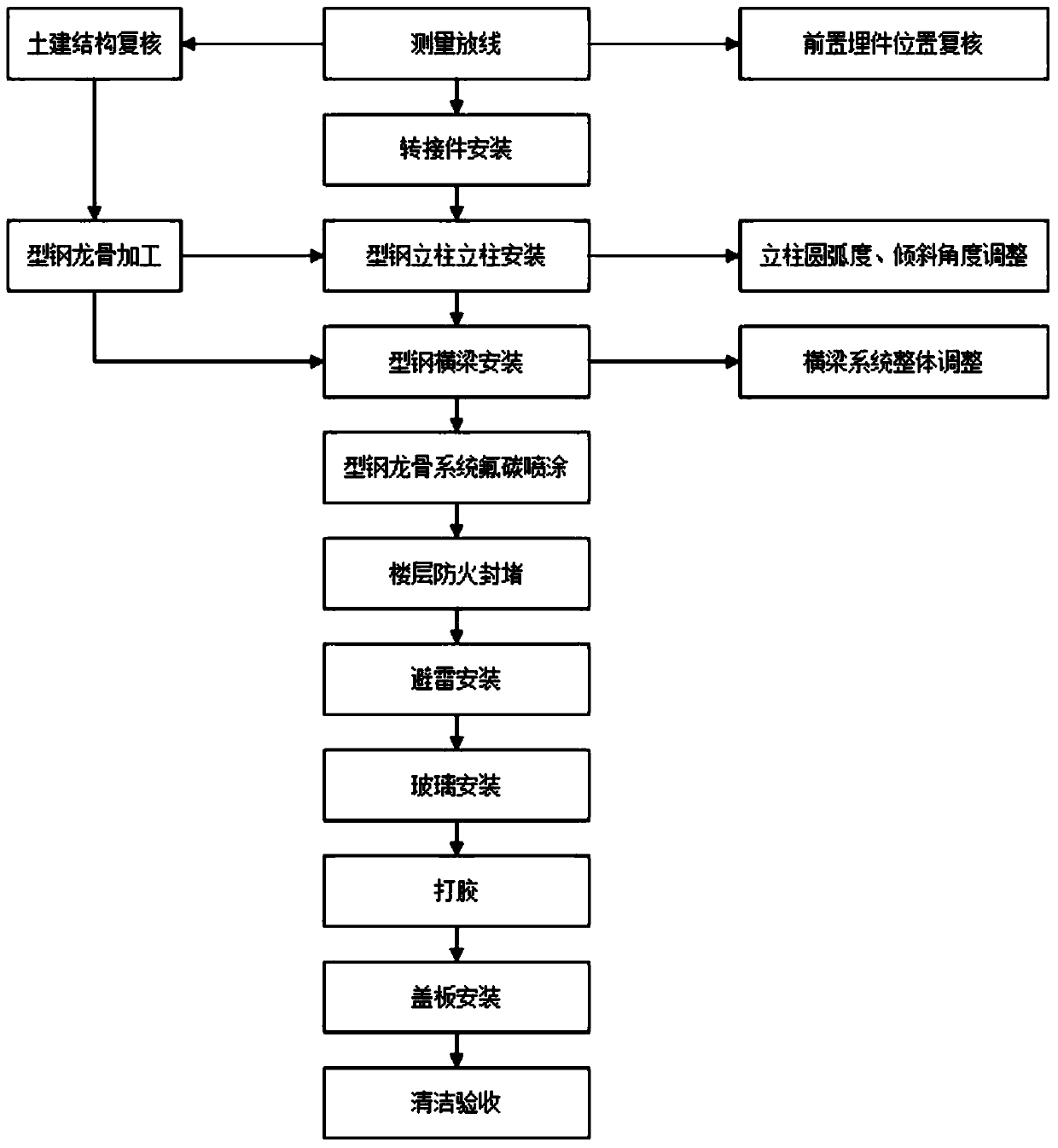

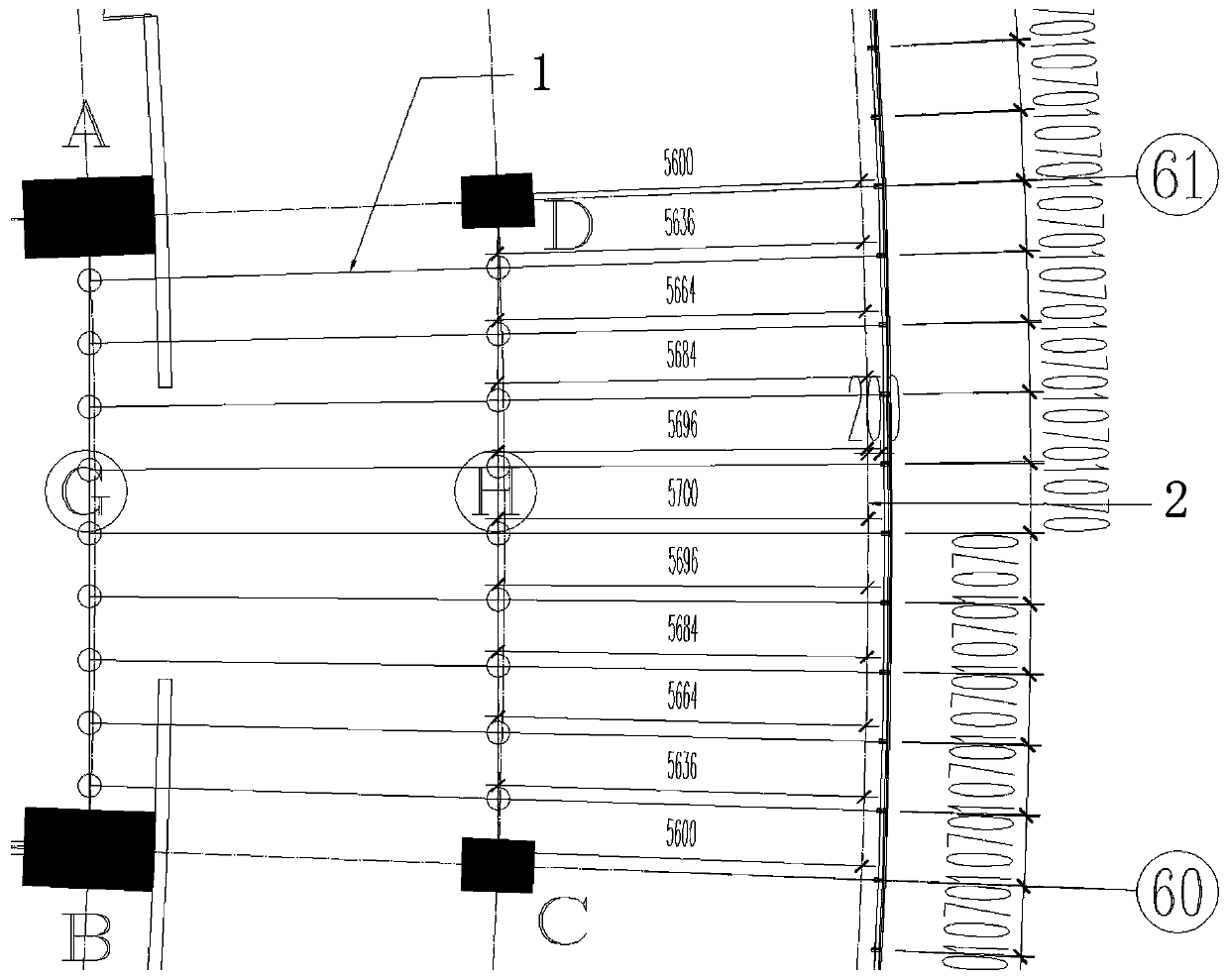

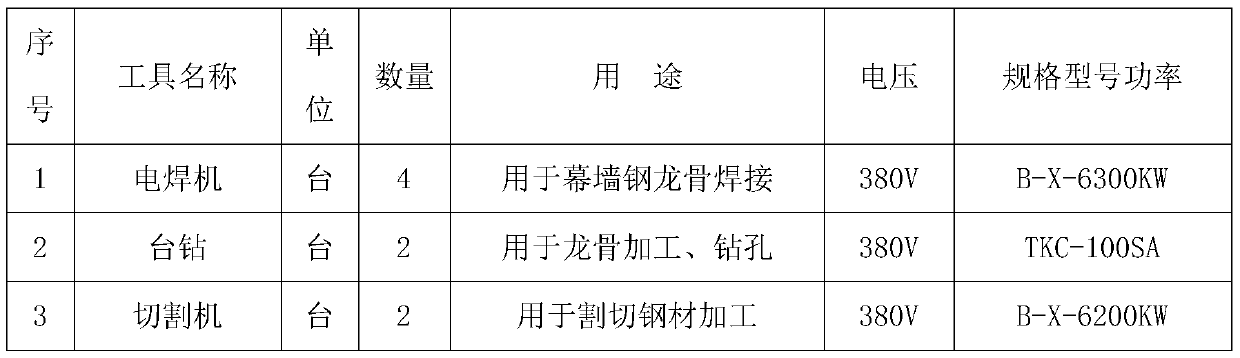

[0061] According to the curtain wall design and construction drawing and on-site measurement, determine the radial grid positioning line and the circumferential depth control line of the curved curtain wall to position the column, and set the radial grid positioning line and the circumferential depth control line through the construction on site The program is played on the floor, and the technical review of the radial grid positioning line and the circumferential depth control line is carried out. For the positioning point of the column, install the steel keel column after checking and checking; after the column is installed, check and adjust the arc, inclination angle, and straightness of the column, and ensure that the highest point of the hyperbolic arc at the top is in the same circle On the arc and on the same level; after the column is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com