Method for automatically drawing standard fan coil manufacturing drawings

A fan coil unit, automatic drawing technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of production workshop affecting production capacity, unable to improve work efficiency, time-consuming and laborious manual drawing, etc., to improve corporate image. , shorten the delivery time, reduce the effect of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

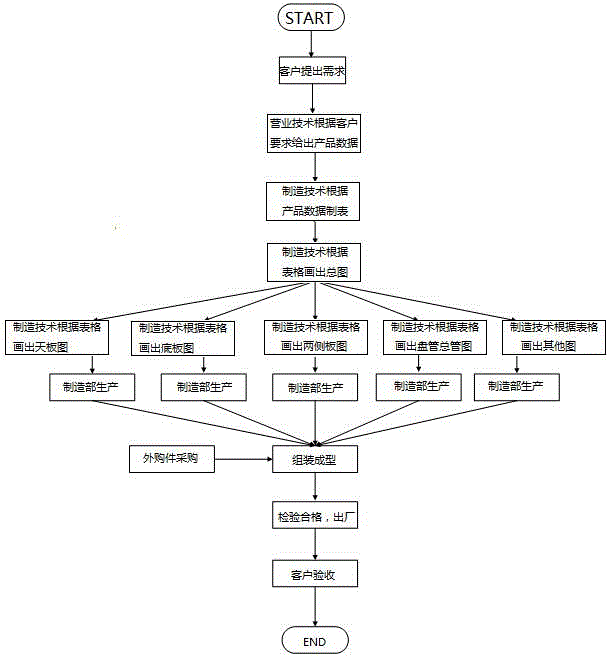

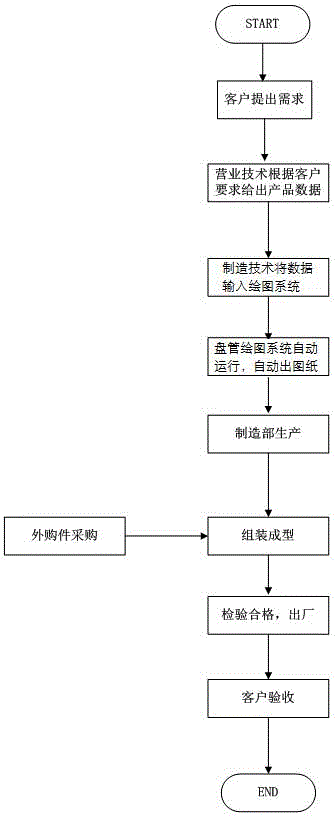

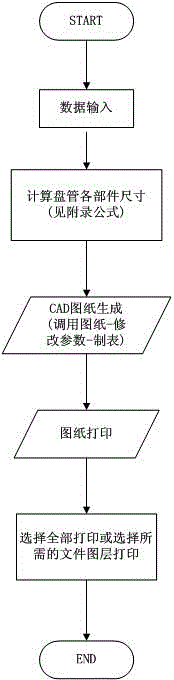

[0019] see Figure 2-3 , a method for automatically drawing production drawings of standard fan coil units, the specific steps are as follows:

[0020] (1) Collection of existing drawings: collect the drawings of standard machines through the drawing system, and directly call and modify the drawings of standard machines according to unused needs when using them. Left and right air outlets and pipe diameters are different, except for similar design drawings, there are 19 categories in total;

[0021] (2) Establish a database: establish a database according to different parameters, and build a parameter table in the database for standby;

[0022] (3) Input condition parameters: input condition parameters through a friendly interface, the condition parameters include the material of the main pipe, the size of the main pipe, the number of coil sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com