Method for manufacturing gas sensor for testing hydrogen

A gas sensor, hydrogen technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to meet the real-time detection of hydrogen, poor sensitivity and selectivity, and achieve excellent structural stability and selectivity, high sensitivity and selectivity The effect of high performance and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

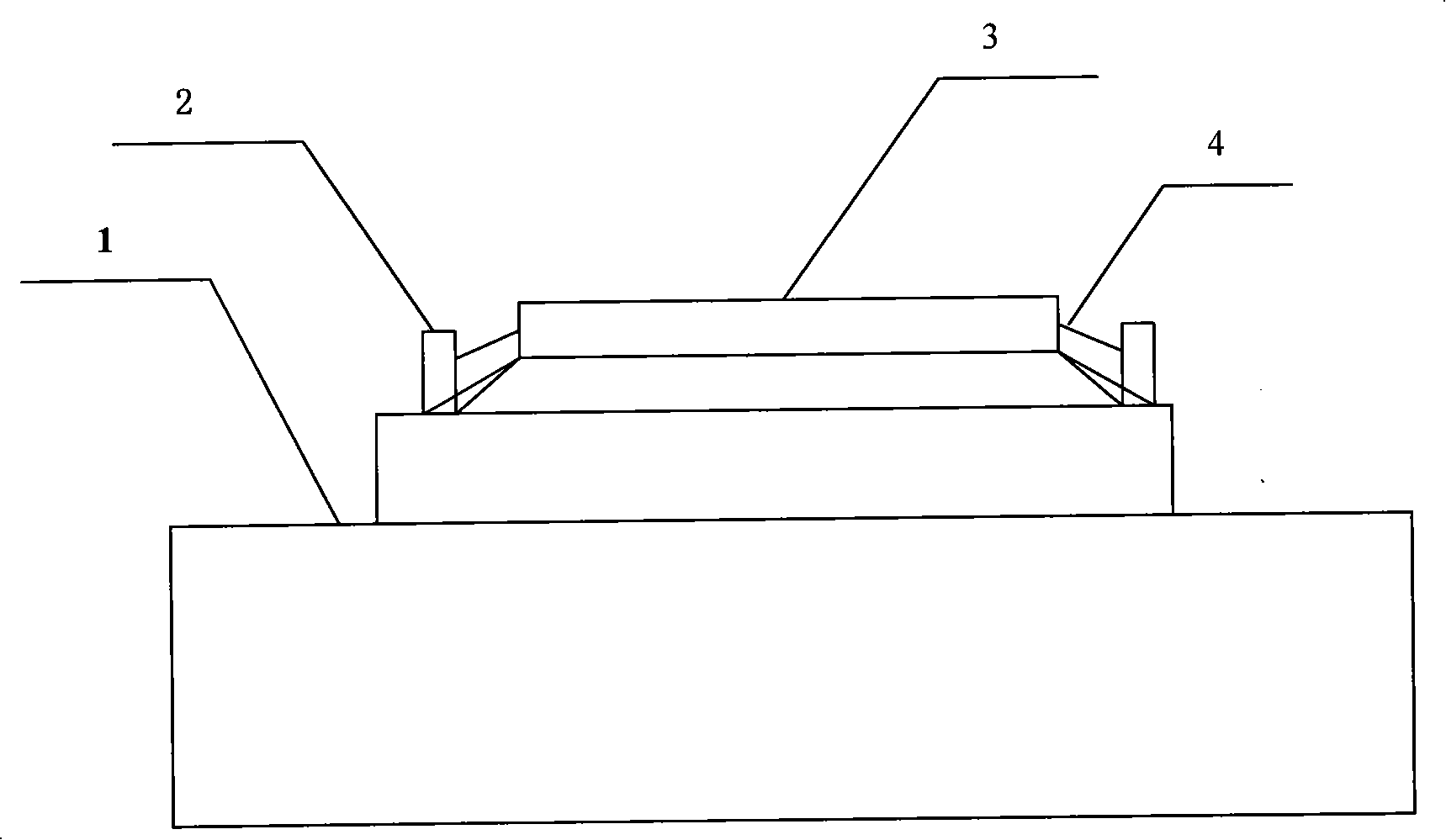

Image

Examples

Embodiment 1

[0030] Preparation of Nano ZnSnO 3 Binder:

[0031] According to cation Zn 2+ / Sn 4+ Zn(SnO 4 ) 2 ·7H 2 O and SnCl 4 ·5H 2 O solution 3L, Zn(SnO 4 ) 2 ·7H 2 The O solution was diluted twice, and the SnCl 4 ·5H 2 O solution was diluted two-fold. To the diluted soluble zinc salt Zn(SnO 4 ) 2 ·7H 2 O solution is slowly dripped with ammonia water with a concentration of 1mol / L, and the pH value of the solution is adjusted to 11; to the diluted SnCl 4 ·5H 2 Concentrated hydrochloric acid was added dropwise to the O solution to adjust the pH of the solution to 6, and magnetic stirring was continued. Adjust the acidity SnCl 4 ·5H 2 O solution was slowly added to adjust the acidity Zn(SnO 4 ) 2 ·7H 2 In the O solution, ammonia water was added dropwise, and the stirring was continued until the solution pH=7, and the precipitate ZnSnO 3 . ZnSnO 3 Precipitation adopts constant temperature water bath magnetic stirrer (produced by Beijing Changfeng Instrument Co., ...

Embodiment 2

[0037] Embodiment two: the PdCl of the present embodiment 2 The addition amount is nanometer ZnSnO 3 8% of base material gross mass, other steps are identical with embodiment one, and the average particle diameter of gained particle is about 45nm, and Pd 2+ Evenly dispersed in ZnSnO 3 in the body.

Embodiment 3

[0038] Embodiment three: the PdCl of the present embodiment 2 The addition amount is nanometer ZnSnO 3 10t% of the total mass of the base material, other steps are the same as in Example 1, and the average particle diameter of the obtained particles is about 55nm, and the Pd 2+ Inhomogeneously dispersed in ZnSnO 3 in the body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com