Method for manufacturing composite film gas sensor

A gas sensor and composite film technology, which is applied in the field of composite film gas sensor production, can solve the problems of potential safety hazards, inability to detect trace gases, and high power consumption, and achieve good gas sensor performance and broad market application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

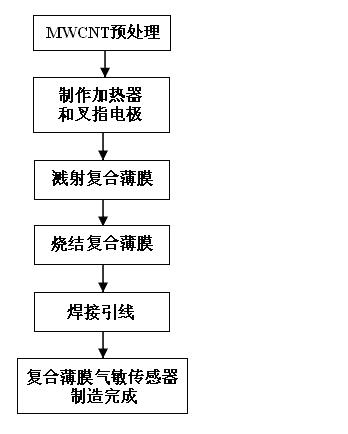

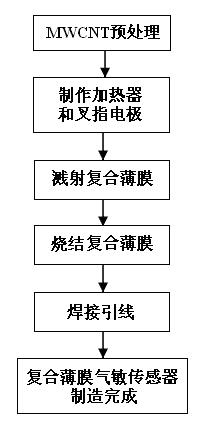

[0020] A kind of manufacture method one of composite film gas sensor of the present invention comprises the following steps:

[0021] (1) Clean the substrate. The cleaning of the substrate is very important. It is necessary to remove the dust, grease and impurities on the surface of the substrate, otherwise it will affect the quality of the sputtered film.

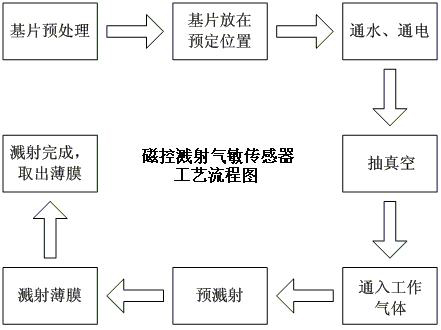

[0022] (2) Acid treatment of MWCNT, acid treatment can effectively remove amorphous carbon impurities in carbon nanotubes, improve the dispersion of carbon nanotubes, then add and disperse MWCNTs in organic solvents, and process them in an ultrasonic oscillator After a period of 2 hours, a well-mixed suspension was obtained, which was then spin-coated respectively on the tin target and the tungsten target of the radio frequency reactive magnetron sputtering equipment;

[0023] (3) Thermally oxidize a layer of SiO on a clean silicon wafer 2 , thickness 500nm;

[0024] (4) Manufacture Al by magnetron sputtering 2 o 3 -T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com