Carbon material pyrolysis device

A carbonaceous material, pyrolysis technology, applied in the direction of coking carbonaceous materials, biofuels, direct heating and dry distillation, etc., can solve the problems of long residence time, secondary decomposition of gaseous tar, and reduction of tar yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

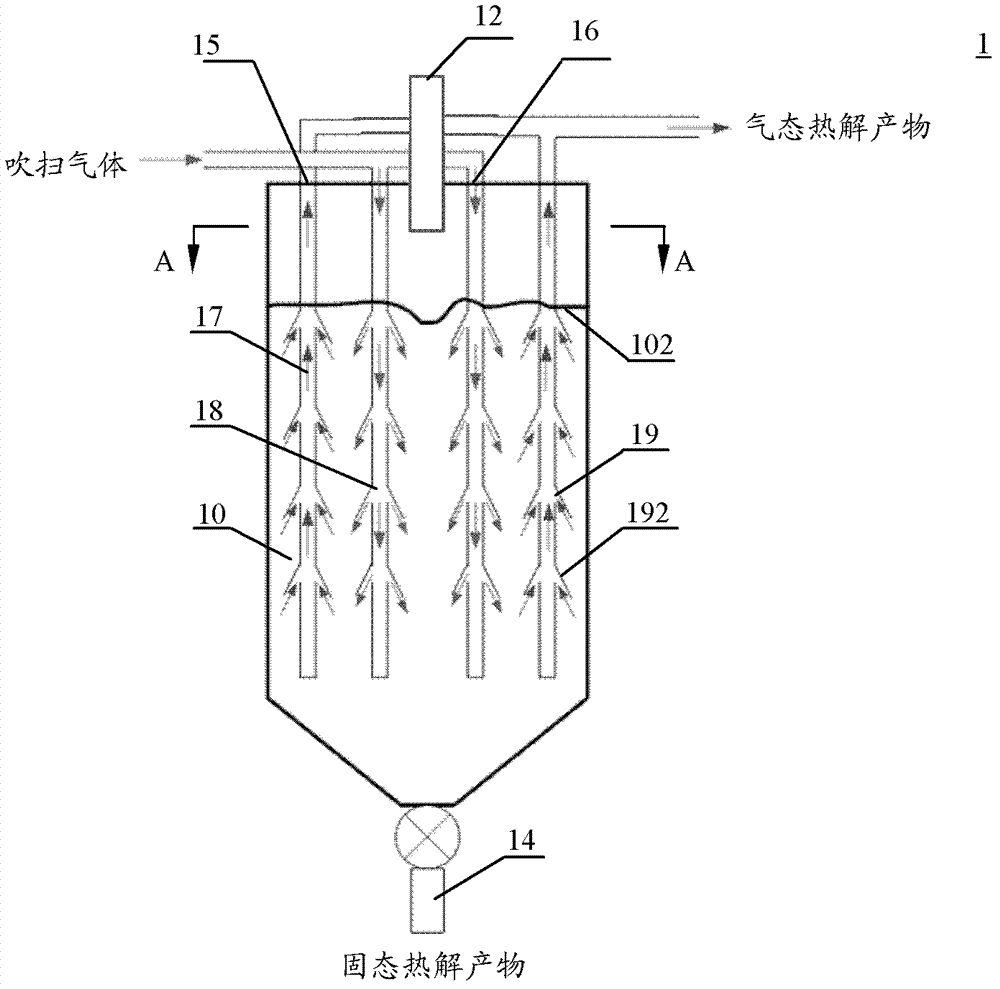

[0043] use figure 1 The pyrolysis or carbonization apparatus of the present invention shown pyrolyzes typical Chinese lignite whose industrial analysis and elemental analysis are shown in Table 1 and Table 2 below. The benchmarks for industrial analysis and elemental analysis are both air-dry bases, while elemental analysis is only for organic matter, excluding ash and moisture.

[0044] Table 1

[0045]

[0046] Table 2

[0047]

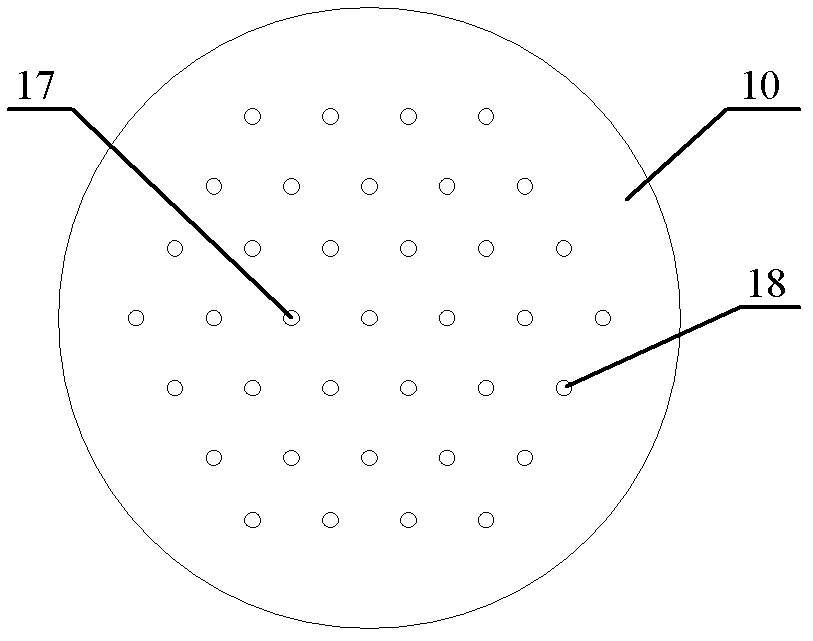

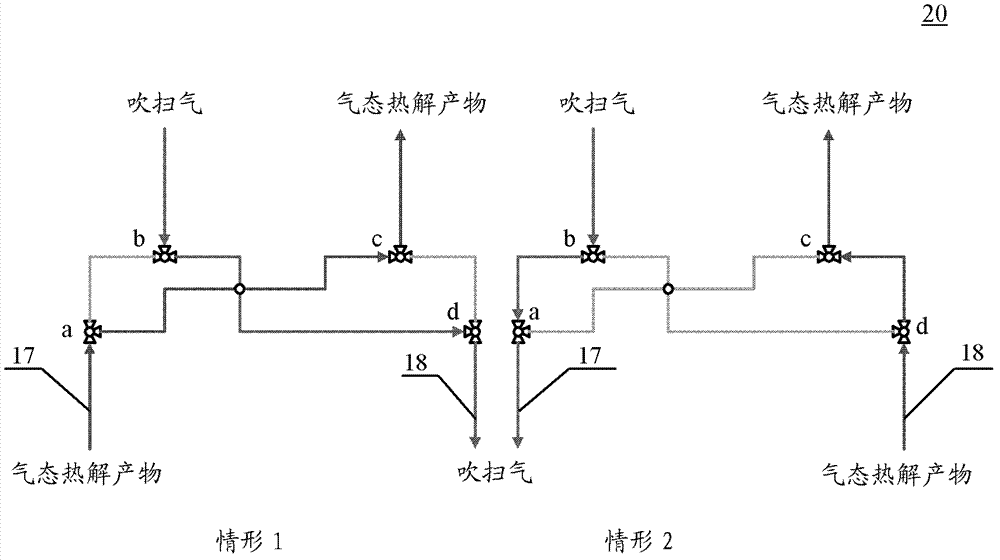

[0048] Described pyrolysis or dry distillation device technological parameter and operating condition are as follows: adopt scale to be the small-scale pyrolysis device of 1000 tons / day, this pyrolysis device is internal diameter 4m, high 20m moving bed pyrolysis reactor, installs in it altogether There are 19 air collecting pipes and 18 air blowing pipes. The inner diameter of the tubes is 0.1 m, and the tube spacing is 0.5 m. The average particle size of lignite particles is 15 mm, and the average particle size of ceramic balls as heat c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com