Pyrolysis device and pyrolysis system for carbonaceous materials

A carbonaceous material, pyrolysis technology, applied in the direction of coking carbonaceous materials, dry distillation gas discharge device, biofuel, etc., can solve the problems of low tar yield, low tar yield, and inability to reflect tar yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

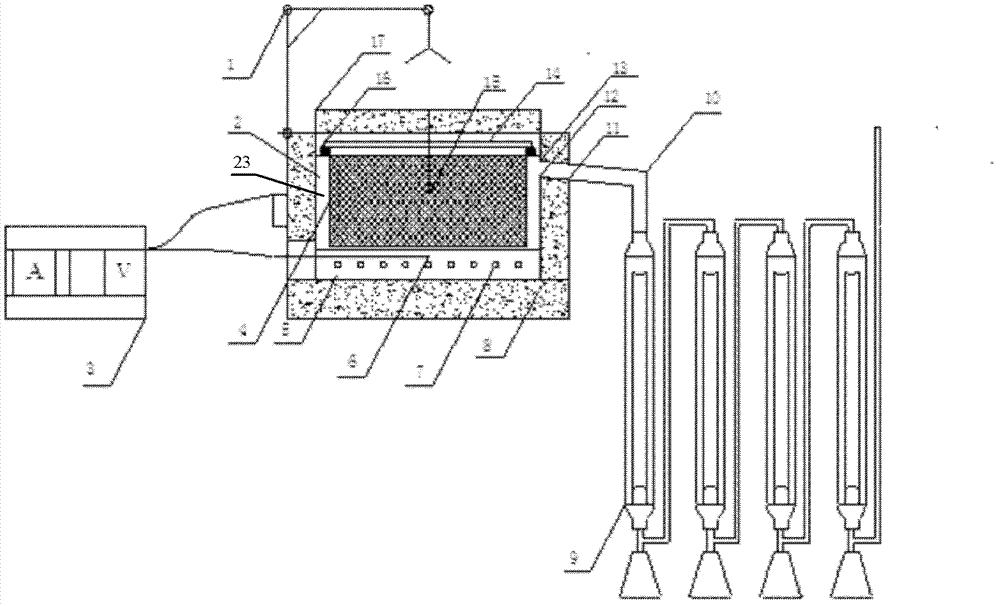

[0049] use figure 1 The shown pyrolysis system of the present invention performs low-temperature pyrolysis of Hulunbeier lignite (I) whose industrial analysis and elemental analysis are shown in Table 1 and Table 2 below. The benchmarks for industrial analysis and elemental analysis are both air-dry bases, while elemental analysis is only for organic matter, excluding ash and moisture.

[0050] Table 1

[0051]

[0052] Table 2

[0053]

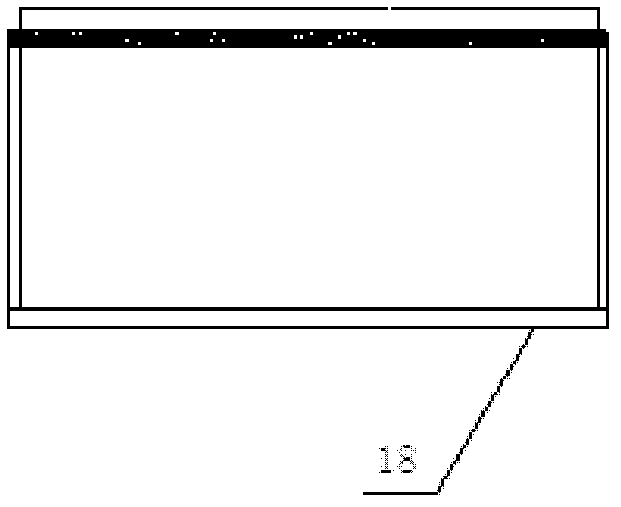

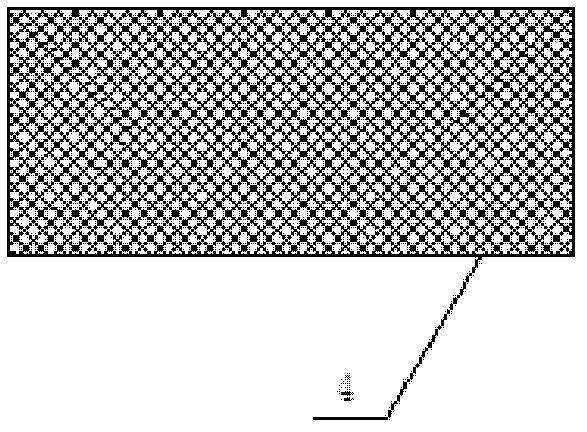

[0054] 5.57 kg of air-dried and pulverized lignite (I) into 2mm is packed into the charging basket 4 made of steel mesh, then it is put into the carbonization chamber 2, the inner layer sealing cover 14 is covered, and the inner layer is sealed. The layer sealing cover 14 is sand-sealed, and then the outer flap type heat preservation cover 17 is covered, and the two ends of the pyrolysis gas outlet pipe 10 are airtightly communicated with the pyrolysis gas outlet 13 and the condensing device 9 respectively.

[0055] The process param...

Embodiment 2

[0062] use Figure 4 The shown pyrolysis system of the present invention performs low-temperature pyrolysis of Hulunbuir lignite (II) whose industrial analysis and elemental analysis are shown in Table 4 and Table 5 below. The benchmarks for industrial analysis and elemental analysis are both air-dry bases, while elemental analysis is only for organic matter, excluding ash and moisture.

[0063] Table 4

[0064]

[0065] table 5

[0066]

[0067] 5.68 kilograms of air-dried and pulverized lignite (II) into 2 mm are packed into the charging basket 4 made of steel mesh, then put it into the carbonization chamber 2, cover the inner layer sealing cover 14, and align the inside The layer sealing cover 14 is sand-sealed, and then the outer flap type heat preservation cover 17 is covered, and the two ends of the pyrolysis gas outlet pipe 10 are airtightly communicated with the pyrolysis gas outlet 13 and the condensing device 9 respectively.

[0068] In this embodiment, thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com