Carbonaceous material destructive distillation system

A technology of carbonaceous materials and dry distillation, which is applied in special forms of dry distillation, coking carbonaceous materials, and discharge devices of dry distillation gas, etc., which can solve the problems of undisclosed specific structure or details, high operating temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

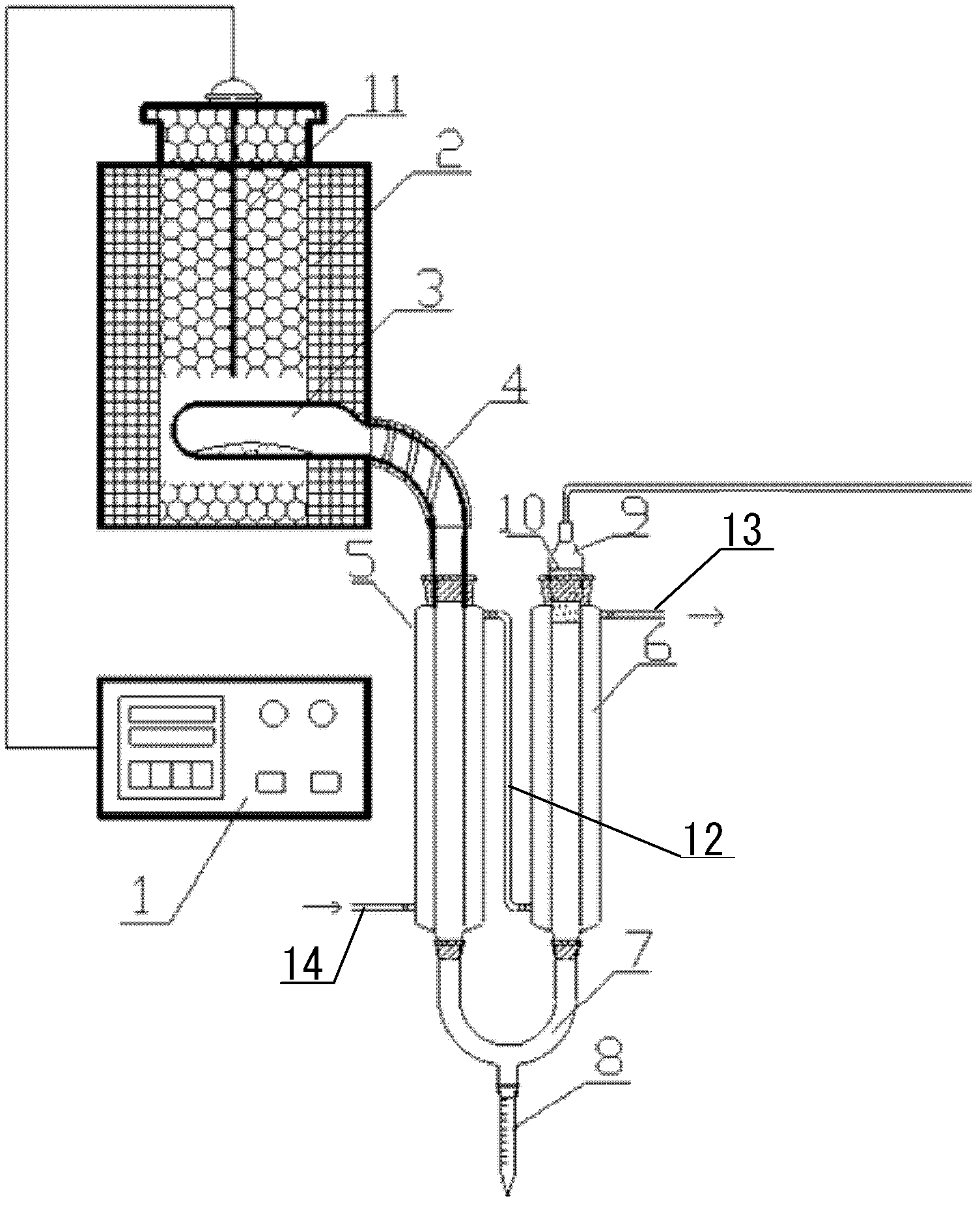

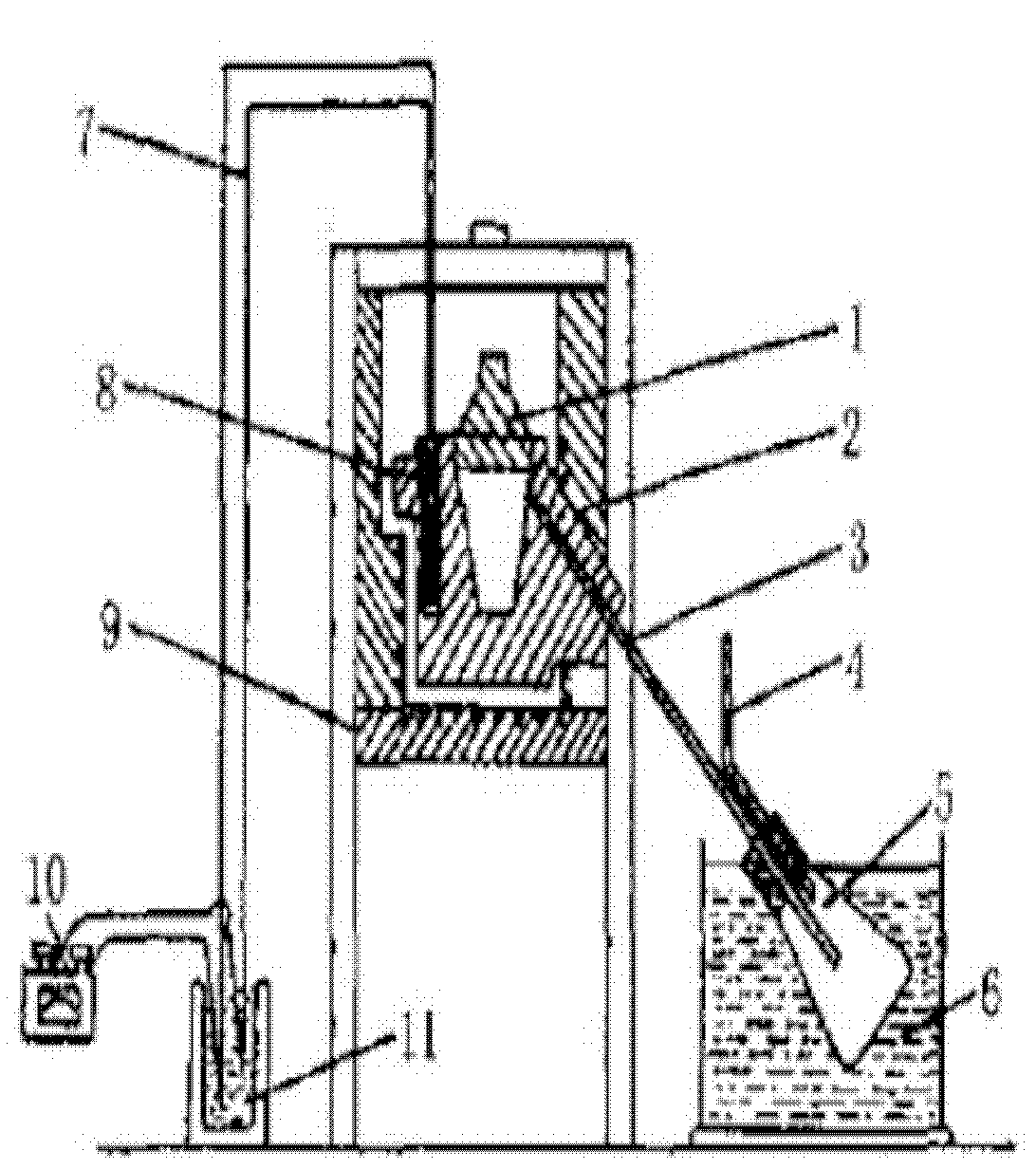

[0031] use figure 1 The shown carbonization system of the present invention performs low-temperature carbonization on lignite (I) whose industrial analysis and elemental analysis are shown in Tables 1 and 2 below. The benchmarks for industrial analysis and elemental analysis are both air-dry bases, while elemental analysis is only for organic matter, excluding ash and moisture.

[0032] Table 1

[0033]

[0034] Table 2

[0035]

[0036] Power on in advance to heat the retort furnace (2) to 300°C, air-dry and pulverize 20 grams of coal samples of 0.2 mm into the dried and emptied pyrolysis chamber (3), and place the pyrolysis chamber (3) Move into the dry distillation furnace (2), and communicate with the recovery device in an airtight manner.

[0037] The technical parameters and operating conditions of the above dry distillation are as follows: initial temperature: 300°C; heating rate: 5°C / min; final temperature: 600°C, constant temperature time at the final temper...

Embodiment 2

[0048] use figure 1 The carbonization system of the present invention shown performs low temperature carbonization of lignite (II) whose industrial analysis and elemental analysis are shown in Table 4 and Table 5 below. The benchmarks for industrial analysis and elemental analysis are both air-dry bases, while elemental analysis is only for organic matter, excluding ash and moisture.

[0049] Table 4

[0050]

[0051] table 5

[0052]

[0053] Air-dried and pulverized to 0.2mm coal sample 20 grams into the dried and emptied pyrolysis chamber (3), move the pyrolysis chamber (3) into the carbonization furnace (2), and communicate with the recovery device .

[0054] The technical parameters and operating conditions of the above-mentioned dry distillation are as follows: the temperature is raised to 260° C. within 15 to 20 minutes, then the temperature is raised to 510° C. at a rate of 5° C. / min, then kept at a constant temperature for 20 minutes, and the heating is stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com