Method for producing high-yield tar by pyrolyzing coal

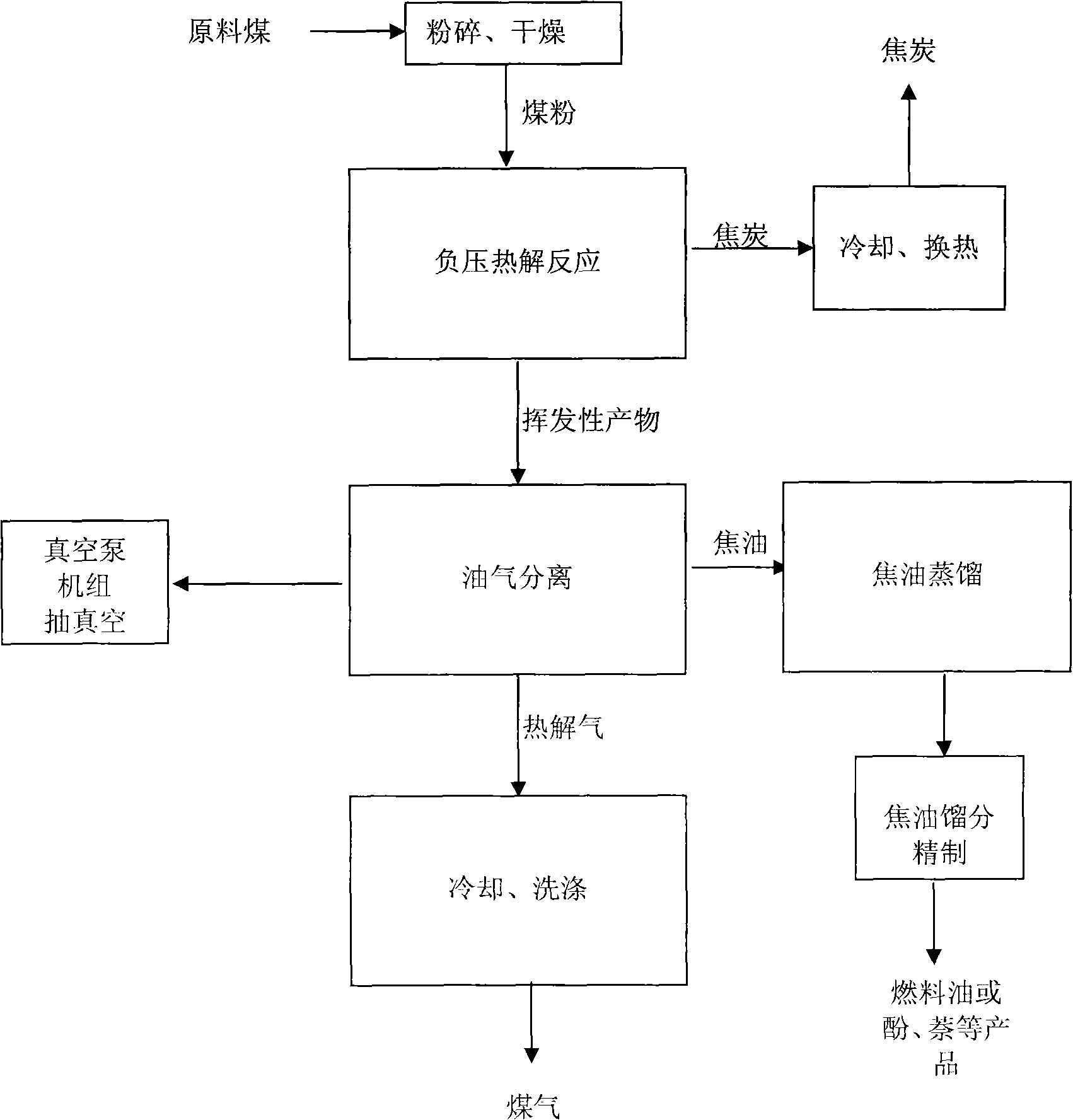

A technology of coal pyrolysis and pyrolysis, which is applied in coking ovens, petroleum industry, special forms of dry distillation, etc. It can solve the problems of low tar yield, unreasonable utilization of low-modified coal, and environmental pollution, etc., and achieve high tar yield , Solve the effect that cannot be used reasonably and reduce the secondary reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

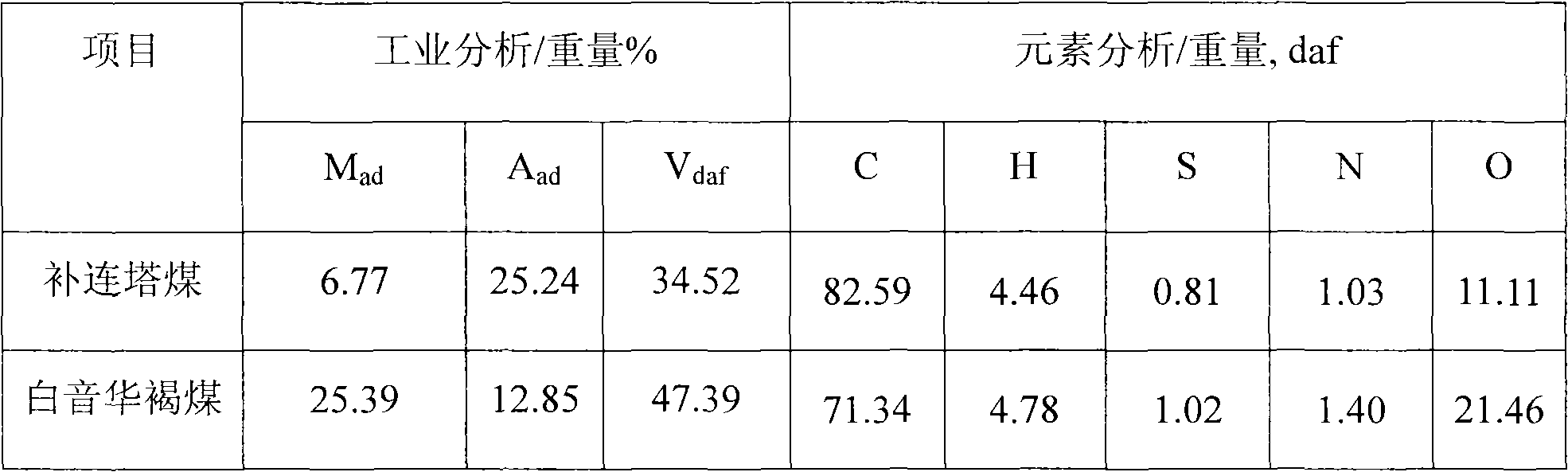

[0029] Baiyinhua lignite is pulverized and sieved to produce 10-1000μm coal powder, which is sent to the pretreatment room for drying and dehydration, and then sent to the fixed-bed intermittent negative pressure pyrolysis reactor. The pyrolysis temperature is 450°C and the pressure is Under the condition of 10kPa (absolute pressure), the pyrolysis takes 1800 seconds, and the volatile products produced by the reaction, including pyrolysis gas and coal tar, escape under the action of the vacuum pump and enter the oil-gas separator. The pyrolysis gas from the oil-gas separator is cooled and washed to obtain coal gas. After the coke is discharged from the negative pressure pyrolysis reactor, it is cooled and used as a coke product or as a raw material for gasification to produce synthesis or hydrogen. The pyrolysis product yields are shown in Table 2.

Embodiment 2

[0033] By adopting the negative pressure pyrolysis method provided by the present invention, the Baiyinhua lignite is subjected to negative pressure pyrolysis according to the same process as in Example 1. The difference is that the pyrolysis temperature is 400°C and the pressure is 50kPa (absolute pressure). The pyrolysis product yields are shown in Table 2.

Embodiment 3

[0035] By adopting the negative pressure pyrolysis method provided by the present invention, the Baiyinhua lignite is subjected to negative pressure pyrolysis according to the same process as in Example 1. The difference is that the negative pressure pyrolysis reactor adopts a fluidized bed, the pyrolysis temperature is 460° C., the pressure is 80 kPa (absolute pressure), and the pyrolysis time is 60 seconds. The pyrolysis product yields are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com