Evaporative cooling equipment of stator winding of hydraulic generator

A technology for hydroelectric generators and generator stators, which is applied in cooling/ventilation devices, electromechanical devices, electric components, etc., can solve the problems that cannot meet the cooling and safety requirements of super-large generator sets, and save investment and operating costs. The effect of simplifying operation management and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

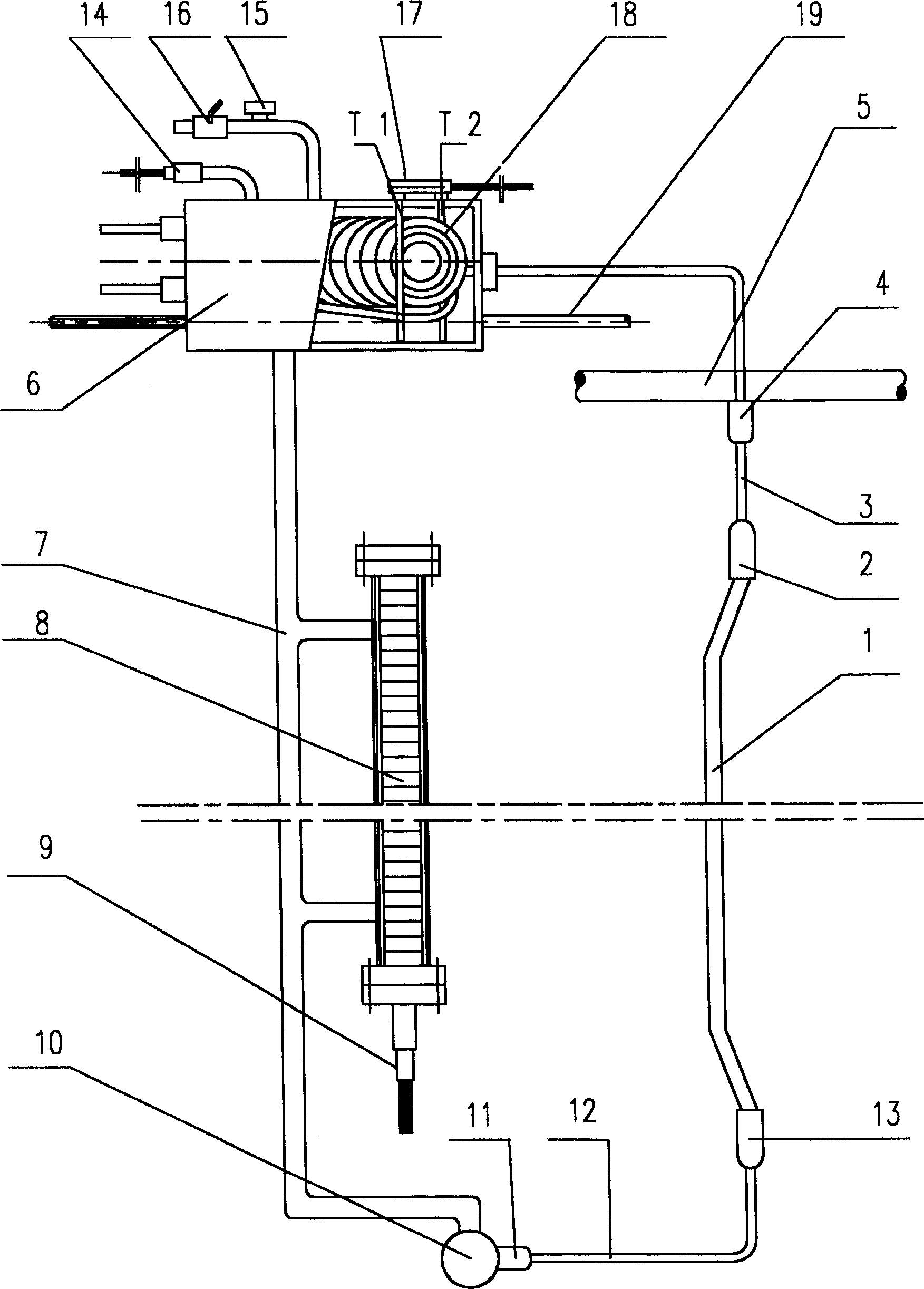

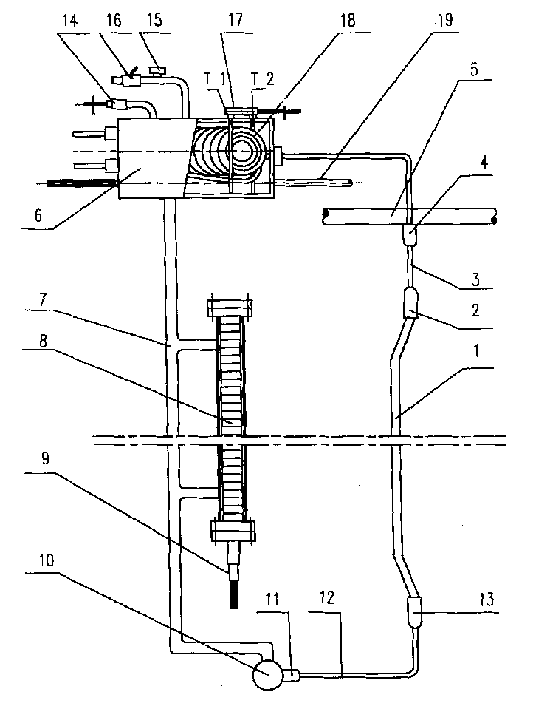

[0020] figure 1 Shown is an evaporative cooling device for the stator windings of a vertical hydroelectric generator. The stator winding 1 is composed of a hollow conductor and a solid conductor, and its upper end is connected with an upper insulating guide pipe 3 through an electro-hydraulic separation joint 2 . The electro-hydraulic separation joint is a fixed part that makes the sealing connection between the insulating lead pipe and the stator winding. The upper insulating guide pipe 3 is connected with the gas collecting pipe 5 through the sealing joint 4, and the gas collecting pipe 5 is connected with the condensing space of the condenser 6 again. The condensation space of the condenser 6 is connected with the liquid return pipe 7, and the liquid return pipe 7 is connected with the magnetic float type liquid level gauge 8 through the communication pipe. A pressure sensor 9 is installed at the lower end of the liquid level gauge. The lower end of the liquid return pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com