Centrifugal contra-rotating ram compressor

A compressor and stamping technology, which is applied in the field of centrifugal counter-rotating stamping compressors and compressors, can solve the problems of minimum flow limitation, large windward area, and difficulty in meeting development requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a limitation to the present invention.

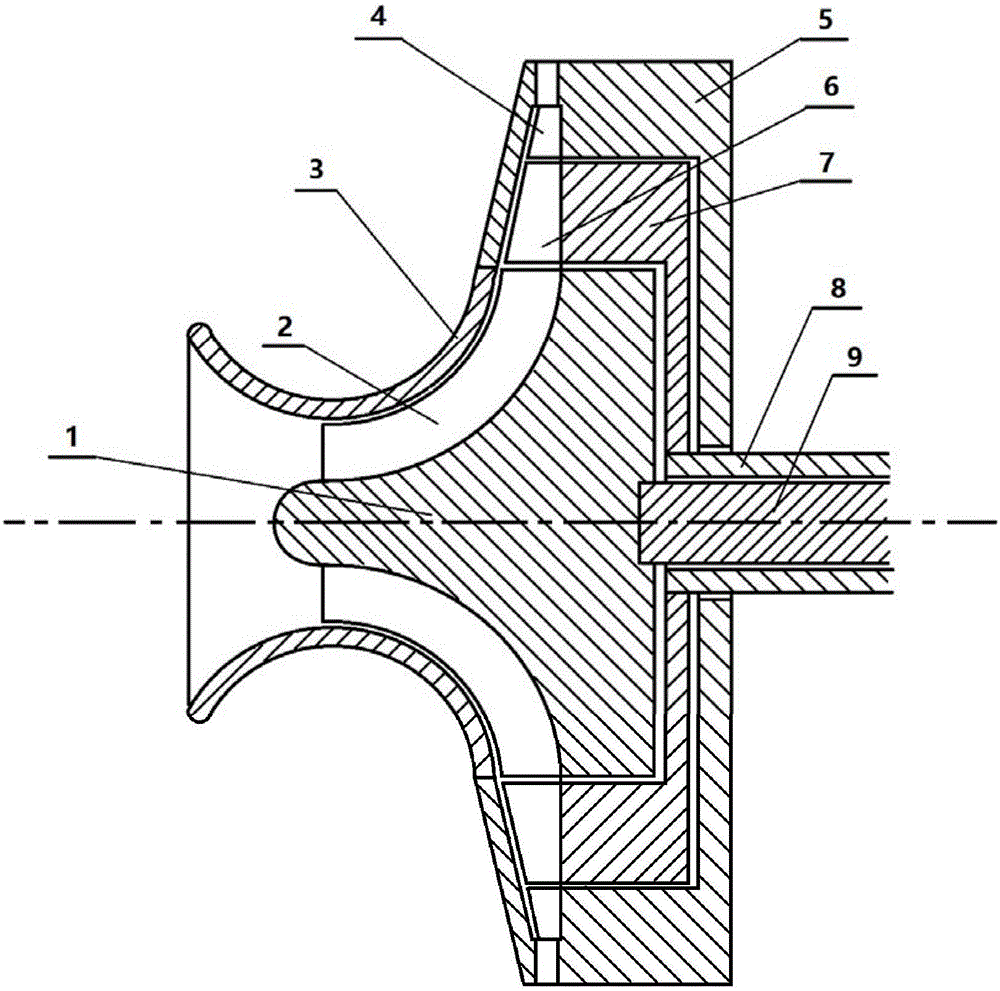

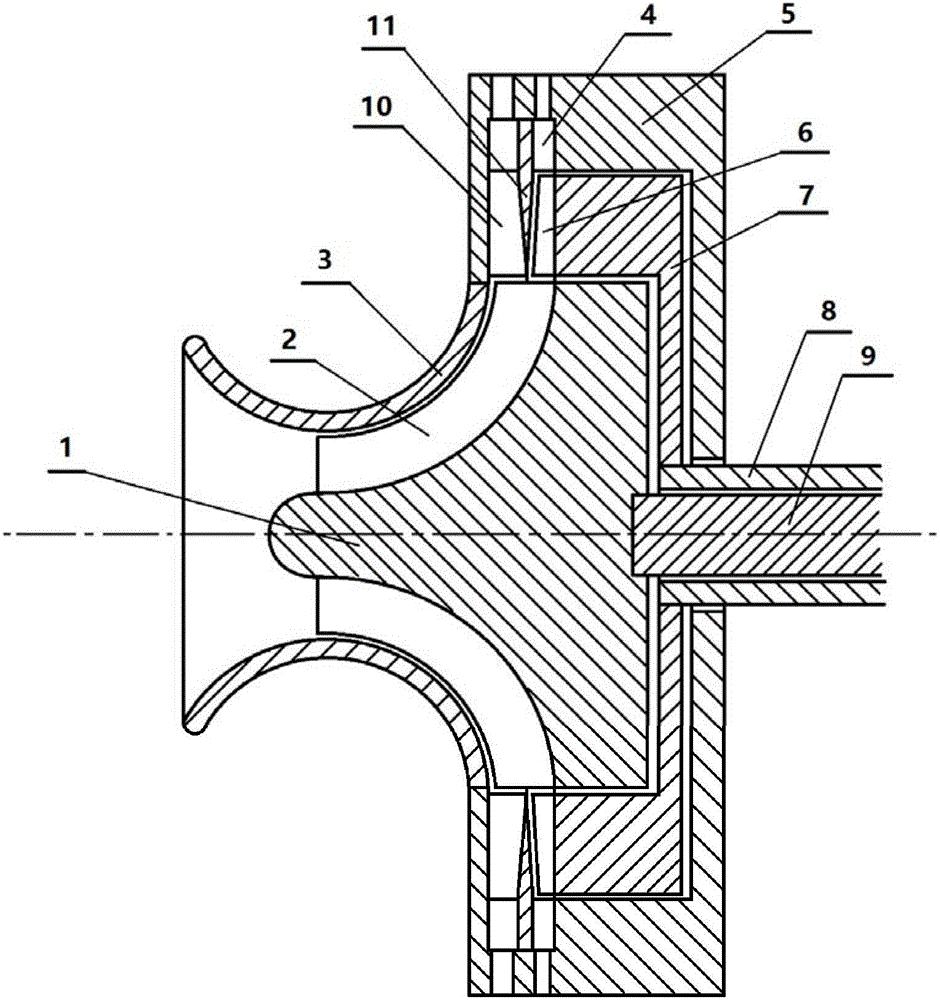

[0018] exist figure 1 In the shown structure, a kind of centrifugal counter-rotating ram compressor designed by the present invention includes an intake system, a transmission device, an impeller and a casing 5; the intake system mainly includes a gas filter device, an intake fairing 3, an inlet Air flow control device, guide wheel, etc., according to the needs, the air intake system and the impeller can be integrated into the design of the small compressor. The transmission device can be set according to specific application requirements, including connecting parts, shafts, speed change mechanisms, etc., which can realize the matching of the speed of the power device and the rotating parts (such as impellers, etc.). The impeller is a circular rotating part, which can be open or closed. It is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com