Heat exchange tube unit, finned tube air-cooled condenser and cooling air evaporator

A technology of heat exchange tubes and monomers, applied in evaporators/condensers, tubular elements, refrigeration and liquefaction, etc., can solve the problems of performance degradation of refrigeration systems, increased loss of refrigerant flow resistance, high product costs, etc. Cost, reduction of flow loss, effect of reduction in metal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the drawings and specific embodiments.

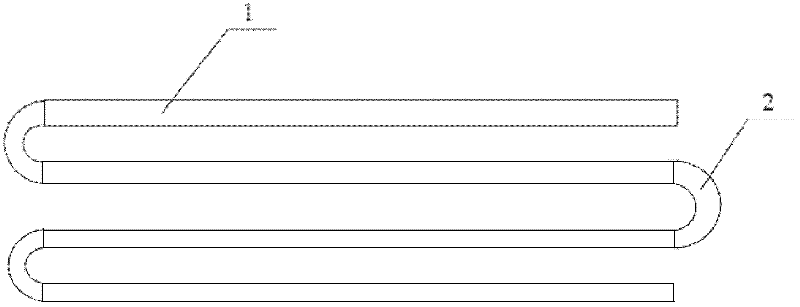

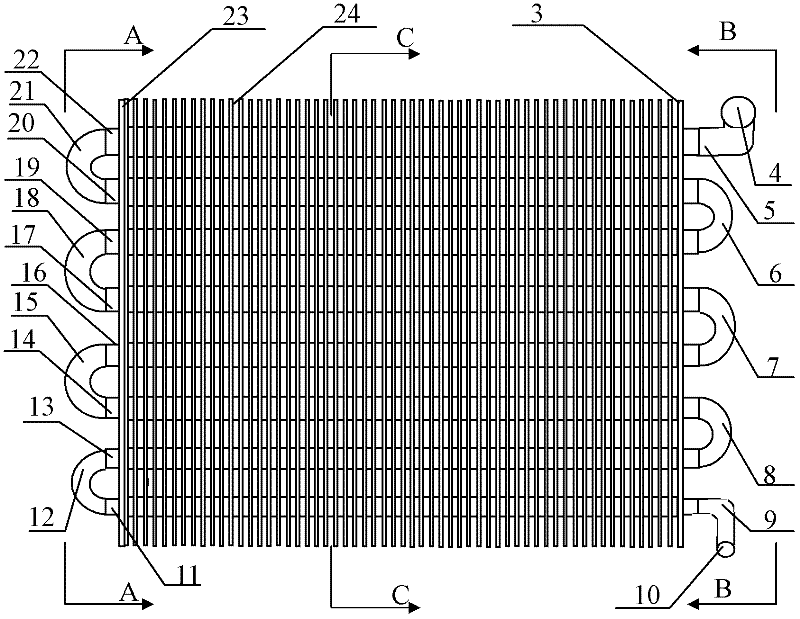

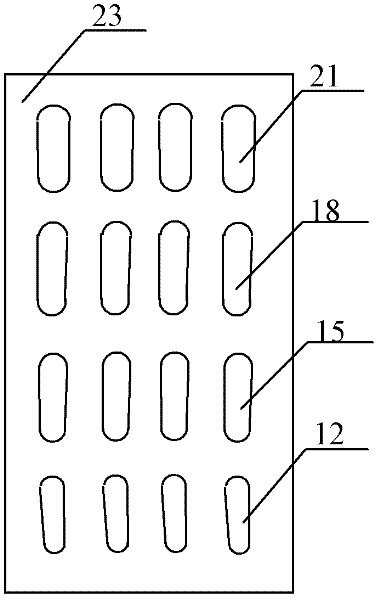

[0023] figure 1 It is a schematic diagram of the heat exchange tube unit of the present invention, including a plurality of heat exchange tube monomers 1 arranged in parallel. The heat exchange tube monomers are connected end to end through elbows 2 to form heat exchange medium channels, adjacent to each other in the direction of increasing gas specific volume The diameter of the arranged heat exchange tube monomers gradually increases, and the bends used for the end to end connection of the heat exchange tube monomers are tapered elbows.

[0024] The heat exchange tube unit of the present invention can be composed of air-cooled condensers, cooling air evaporators and other products according to the needs of the use environment. The heat exchange tube units can be arranged horizontally or vertically, and the heat exchange tube monomers in the heat exchange tube u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com