Gas discharging apparatus for waste reclaimed land

A gas discharge and gas technology, applied in landfill technology, gas/liquid distribution and storage, solid waste removal, etc., can solve problems such as hindering gas flow and ineffective use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Through the following detailed description in conjunction with the accompanying drawings, a more in-depth understanding of the present invention and its beneficial effects can be obtained.

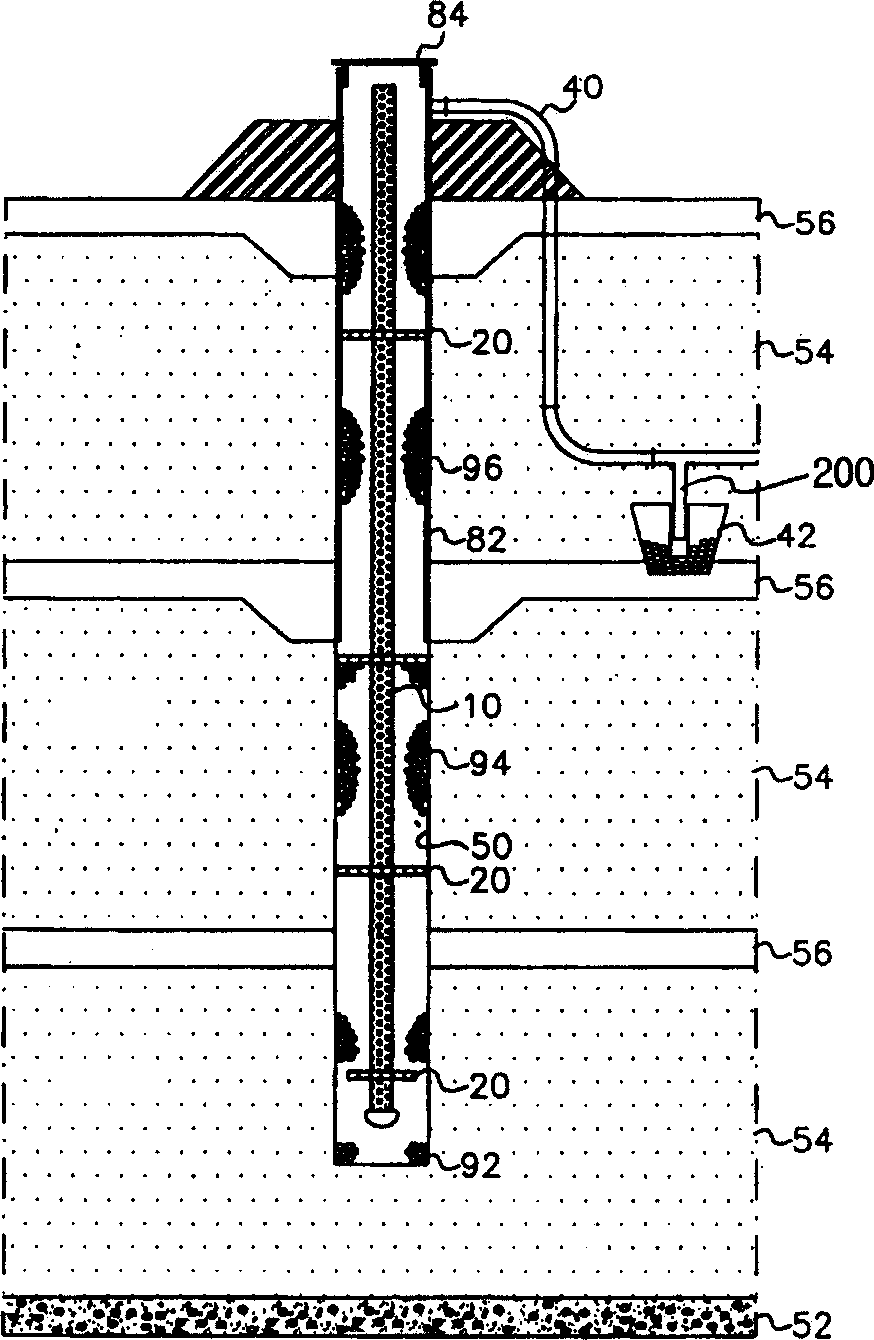

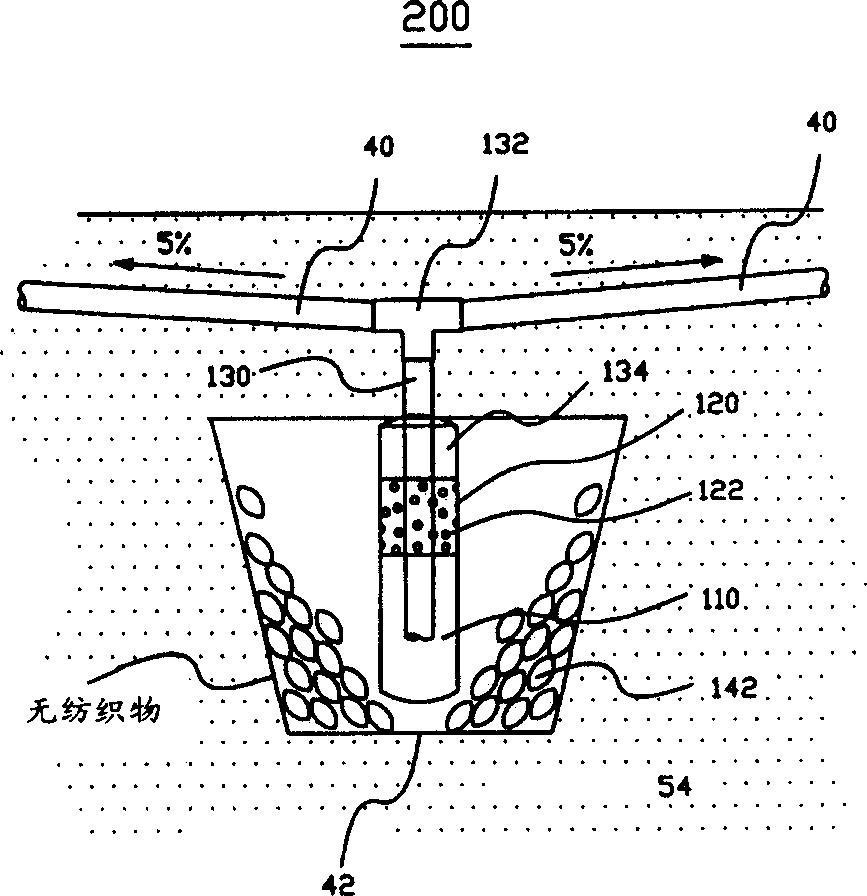

[0011] figure 1 is a diagram showing a gas discharge device installed in a landfill site according to an embodiment of the present invention. Such as figure 1 As shown, the leachate drainage layer 52 is located at the bottom of the landfill site, and at least one garbage layer 54 is formed on the leachate drainage layer 52 (in which the garbage is recycled to a predetermined height). Likewise, a cover soil layer 56 is located on the refuse layer 54, and the cover soil layer 56 is formed of a cover material such as soil or the like. A hole 50 is formed to a predetermined depth through the garbage layer 54 , and the gas collection pipe 10 is placed in the hole 50 . If possible, a spacer 20 and a steel pipe 82 may be further installed to maintain a gap between the garbage layer 54 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com