Wet construction method for coverage system of refuse landfill sewage adjusting tank

A technology for a landfill and a construction method, applied in the field of landfill construction, can solve the problems of no construction method, large span, and high engineering cost, and achieve the effects of cost reduction, reduction of folds, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

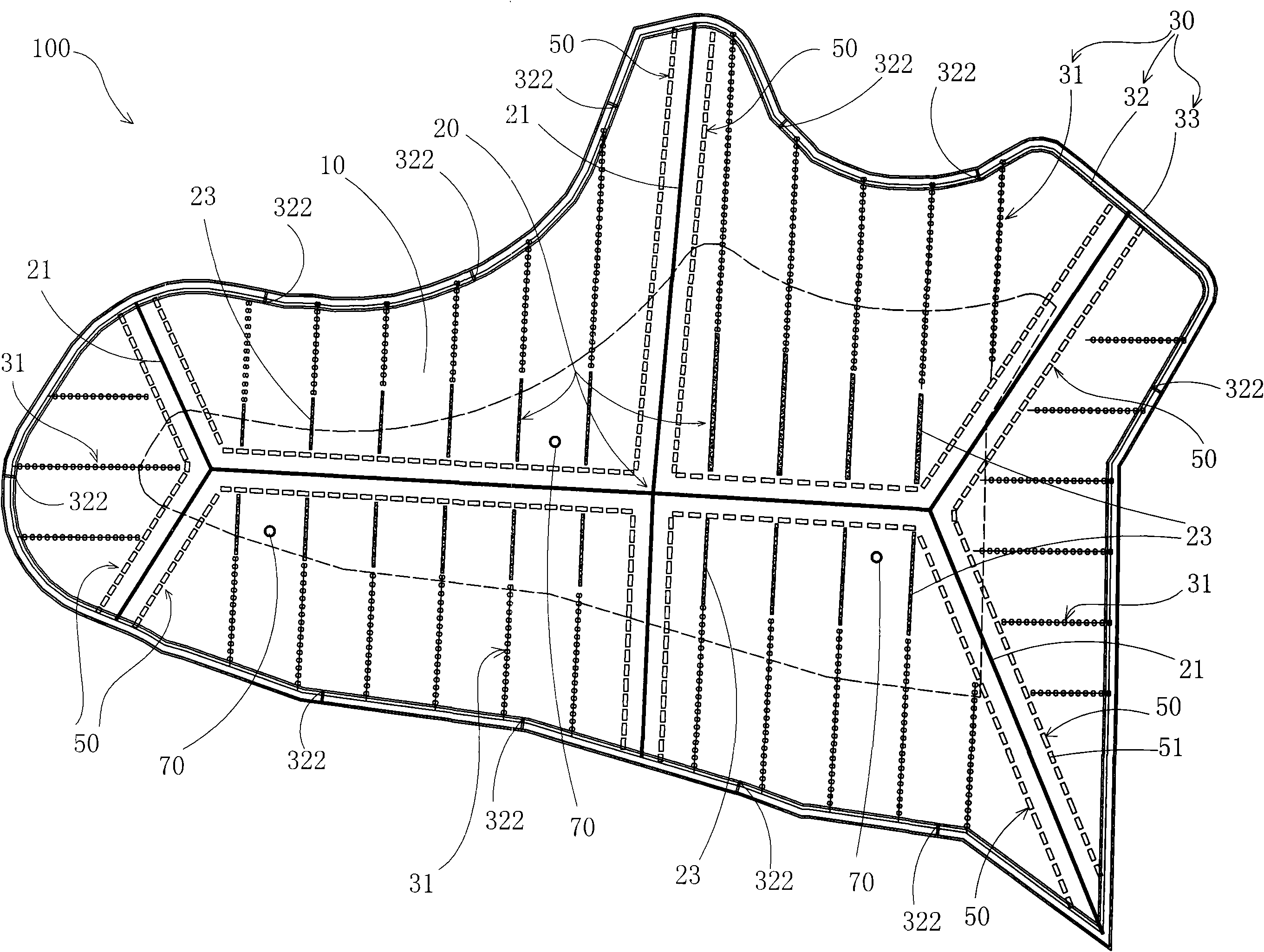

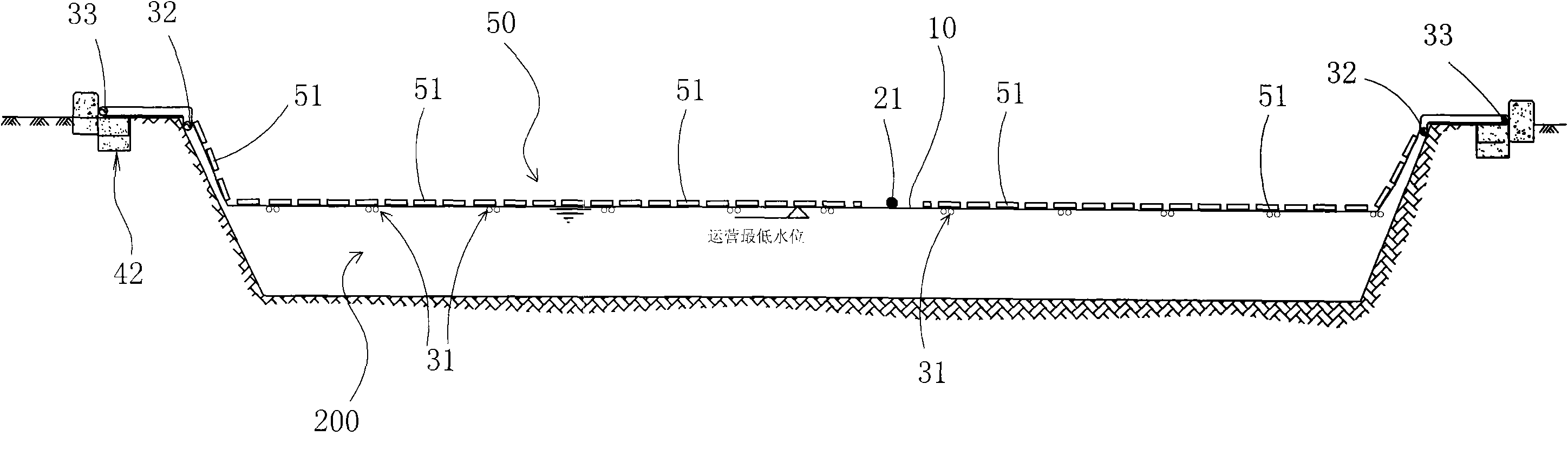

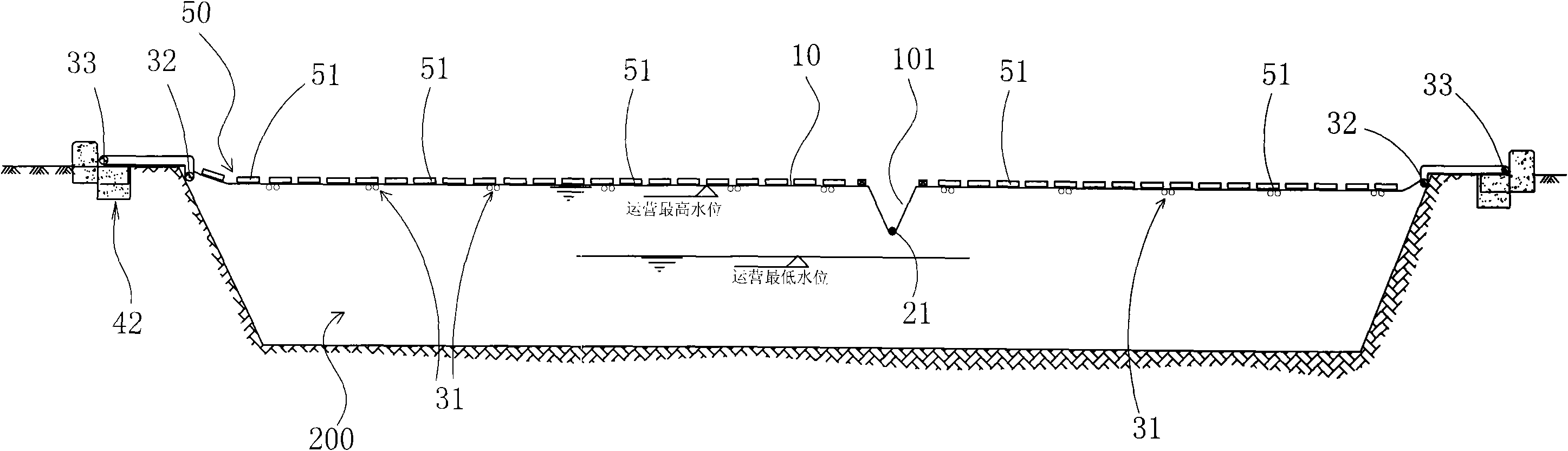

[0053] Such as figure 1 Shown is the covering system 100 of the sewage conditioning tank of a waste landfill of the present invention, which includes a floating cover film 10, a gravity ballast device 20, a gas guiding device 30, an anchoring device 40, a pedestrian passage 50 or a water-proof pedestrian passage 60, Maintenance hole device 70.

[0054] Such as Figure 1-7 As shown, the floating cover film 10 is a whole formed by welding several pieces of 2.0mm thick double-gloss HDPE film. The floating cover film covers the water surface of the sewage conditioning tank 200, and the edges of the floating cover film are anchored The device 40 is anchored outside the adjustment tank, and the floating cover film seals the sewage surface in the adjustment tank, and can float and fluctuate with the change of the sewage level of the liquid level in the adjustment tank. The floating cover film 10 of the present invention must use materials with good impermeability and anti-aging properti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com