Novel grinding dust treatment equipment

A dust treatment and equipment technology, which is applied in the field of new grinding dust treatment equipment, can solve the problems of slow dust collection speed, treatment effect that cannot meet expectations, and failure to popularize and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

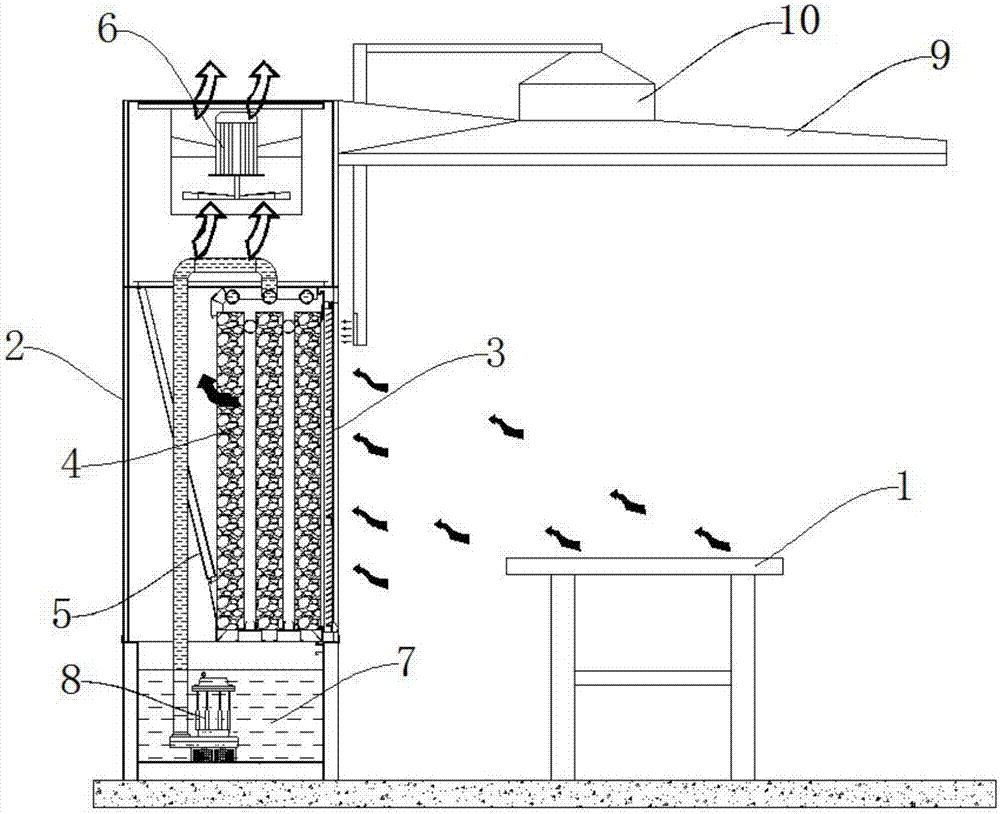

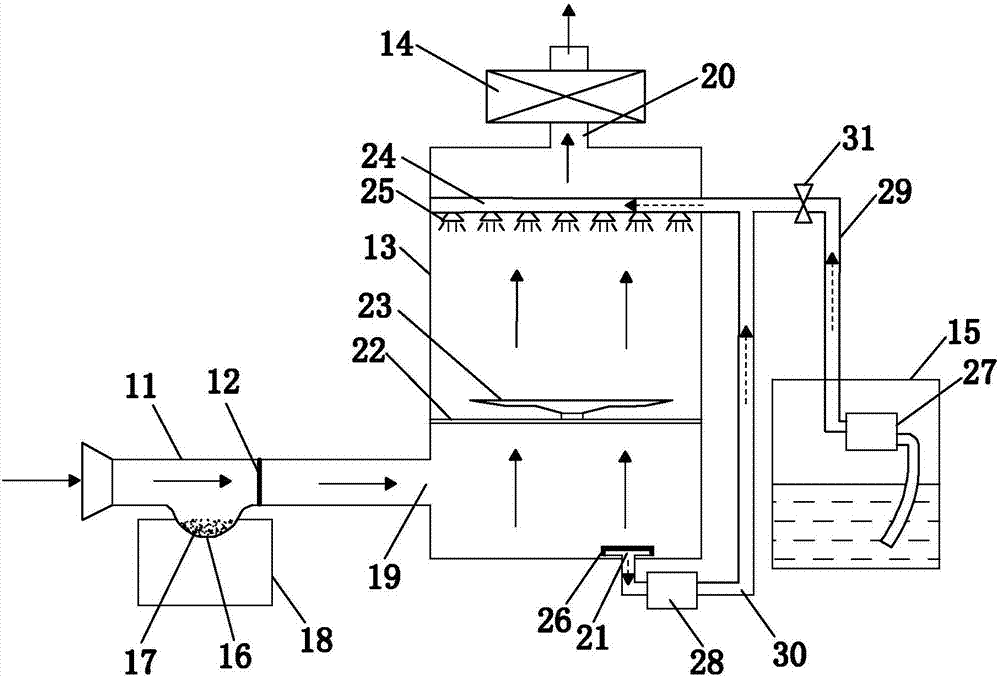

[0018] The invention provides a new type of grinding dust treatment equipment, which comprises a first dust treatment equipment and a second dust treatment equipment.

[0019] Such as figure 1 As shown, the structure diagram of the first dust treatment equipment in a new type of grinding dust treatment equipment of the present invention, the first dust treatment equipment is a water washing type dust treatment equipment, and the first dust treatment equipment includes a polishing workbench 1, a dust suction box 2 And the vacuum shed 9, the polishing workbench 1 is provided with a vacuum box 2 on the side opposite to the staff standing, and a second dust processing device is provided between the vacuum box 2 and the polishing workbench 1, and the vacuum box 2 is The second dust treatment equipment is provided with an inlet grill 3 on the adjacent side. The dust suction box 2 is equipped with a filter plate 4 and a water shield 5, and the water shield 5 is installed obliquely inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com