An automatic slag removal system for small and medium hydropower stations

A small hydropower station, automatic technology, used in water conservancy projects, open water surface cleaning, construction and other directions, can solve the problems of difficult transfer, affecting generator power, generator impeller damage, etc., to ensure high efficiency, simple structure, and guaranteed strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

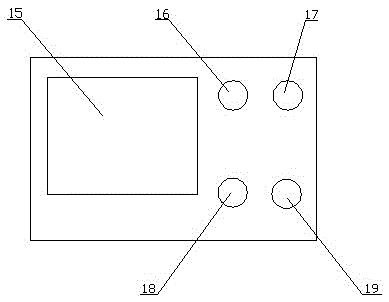

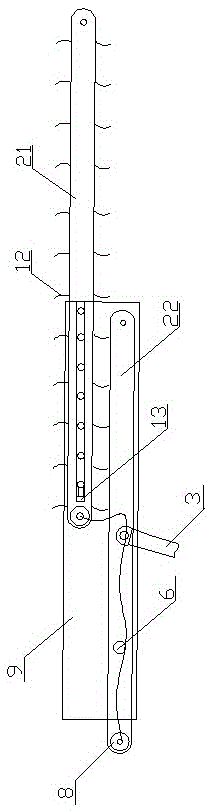

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 Shown: an automatic slag removal system for small and medium hydropower stations, including a transmission mechanism 2, a slag removal mechanism 7, a storage tank 1 and a controller. It is connected with the conveying mechanism 2, the conveying mechanism 2 is connected with the material storage tank 1, and the conveying mechanism 2 and the slag removing mechanism 7 are connected with the controller through wires.

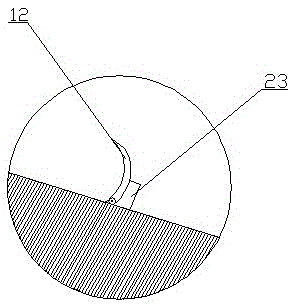

[0021] The slag removal mechanism 7 includes a conveyor belt 22, a support 9, a hydraulic telescopic module 13, a gantry support 14, and a slag removal rake 21. The slag removal rake 21 and the conveyor belt 22 are arranged side by side on the support 9. The upper ends of the rakes 21 are provided with driving motors 8, the hydraulic telescopic module 13 is connected with the slag removal rake 21, the gantry support 14 is fixedly connected with the forebay 20, and the upper end of the gantry support 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com