A new material color masterbatch spiral dispersion dryer

A color masterbatch and spiral type technology, which is applied in the field of new material color masterbatch spiral dispersion dryers, can solve the problems of reducing the degree of ABS color masterbatch aggregation and the decline in the drying effect of ABS color masterbatch, so as to avoid stagnation in the The edge of the spiral blade prevents mutual crowding and avoids the effect of spring blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Such as Figure 1-Figure 5 Shown:

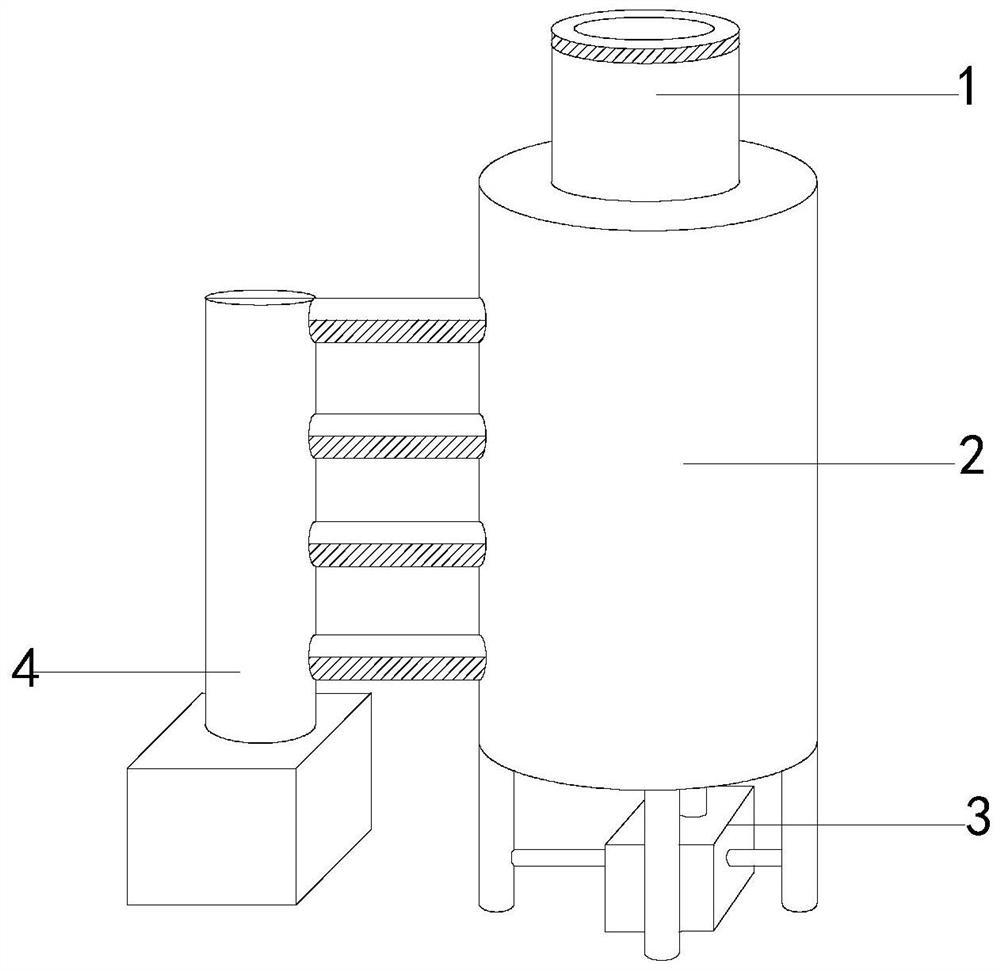

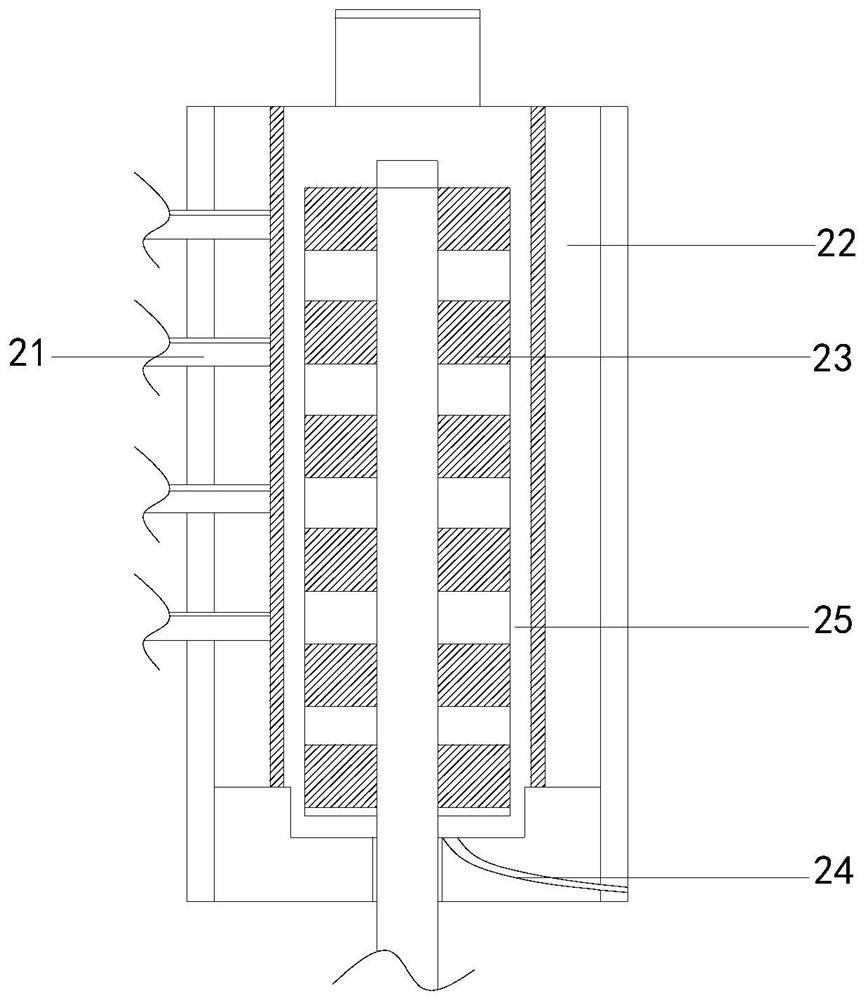

[0024] The present invention is a new material color masterbatch spiral dispersion dryer, its structure includes a feed port 1, a drying tank 2, a power device 3, and a heat generator 4, and the feed port 1 is welded on the drying tank 2 At the upper end, the power device 3 is embedded and installed under the drying tank 2, and the hot air machine 4 is embedded and installed on the left side of the drying tank 2. The drying tank 2 is composed of a hot gas pipe 21, a dryer 22 , a rotating mechanism 23, a discharge port 24, and a drying box 25. The hot gas pipe 21 is welded to the right end of the hot air machine 4, and the rotating mechanism 23 is embedded in the power device 3. The drying box 25 is connected to the The central point of the rotating mechanism 23 is the same axis, the discharge port 24 is attached to the right side of the rotating mechanism 23, the hot gas pipe 21 and the dryer 22 are an integrated structure, and the d...

Embodiment 2

[0031] Such as Figure 6-Figure 7 Shown:

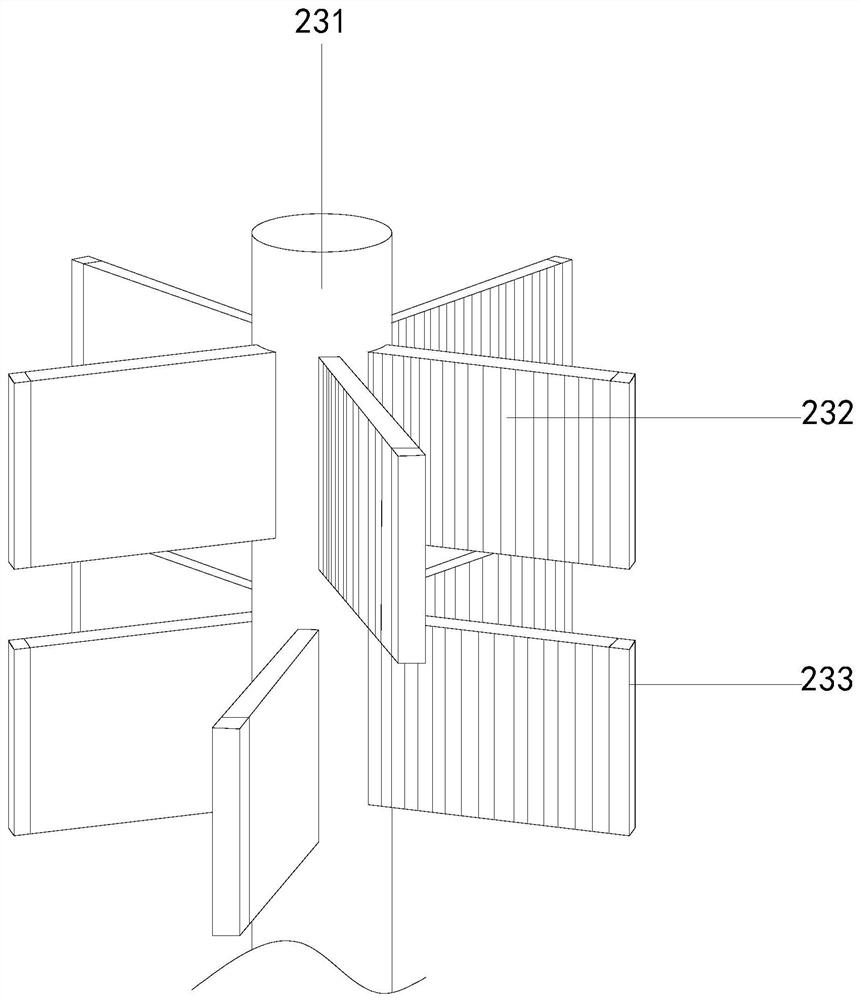

[0032] Wherein, the elastic mechanism 233 is provided with an elastic block b1, a spring b2, a stressed block b3, and a contraction plate b4, the right side of the elastic block b1 is attached to the left side of the stressed block b3, and the two sides of the spring b2 are fixed on The left and right sides of the elastic block b1, the shrinkable plate b4 is attached to the front and rear sides of the elastic block b1, and the left side of the elastic block b1 is attached to the outer side of the rotating blade 232. There are two shrinkable plates b4, which have a relatively Strong flexibility prevents ABS color masterbatch from entering the elastic block b1. The spring b2 is provided with three, which are evenly distributed inside the elastic block b1, so that the stressed block b3 can generate greater resilience when squeezed. The ABS color masterbatch inside the oven 25 is dispersed.

[0033]Wherein, the stressed block b3 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com