Device and method for processing gases with offensive odor by utilization of biofiltration-active carbon combination method

A biological filtration and malodorous gas technology, applied in separation methods, chemical instruments and methods, air quality improvement, etc., can solve problems such as complex management operations, secondary pollution, and small scope of application, and achieve simple operation and maintenance, and reduce The effect of air intake load and compact structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

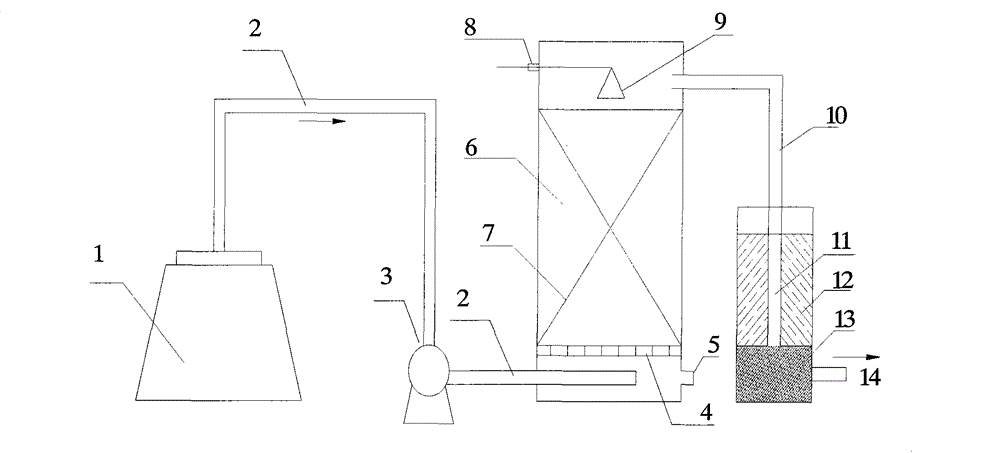

[0030] See figure 1 . A biofiltration-activated carbon combined method made of plexiglass to treat malodorous gas mainly consists of a negative pressure collection unit 1, a gas collection pipe 2, a fan 3, a biological filtration unit 6 and an activated carbon adsorption unit 11 connected in sequence.

[0031] There is a gas distribution device 4 at the bottom of the biological filtration unit 6, and the interior is filled with light-weight active biological fillers 7. The gas distribution device also serves as a supporting filler. There is a nutrient solution spray inlet 8 on the side wall and a spray nozzle connected to the nozzle is installed. 9, the sprinkler is above the filler of the biological filtration unit, regularly sprays the nutrient solution through the pipeline, and the nutrient solution is recycled, and the bottom is provided with a drain port 5.

[0032] The outlet gas of the biological filter unit is connected with the activated carbon adsorption unit 11 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com