Refining furnace of silicon carbide for recovering smelting waste gases

A silicon carbide and smelting furnace technology, applied in the field of silicon carbide smelting, can solve the problems of no recycling, energy waste, etc., and achieve the effects of easy furnace installation, air pollution reduction, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

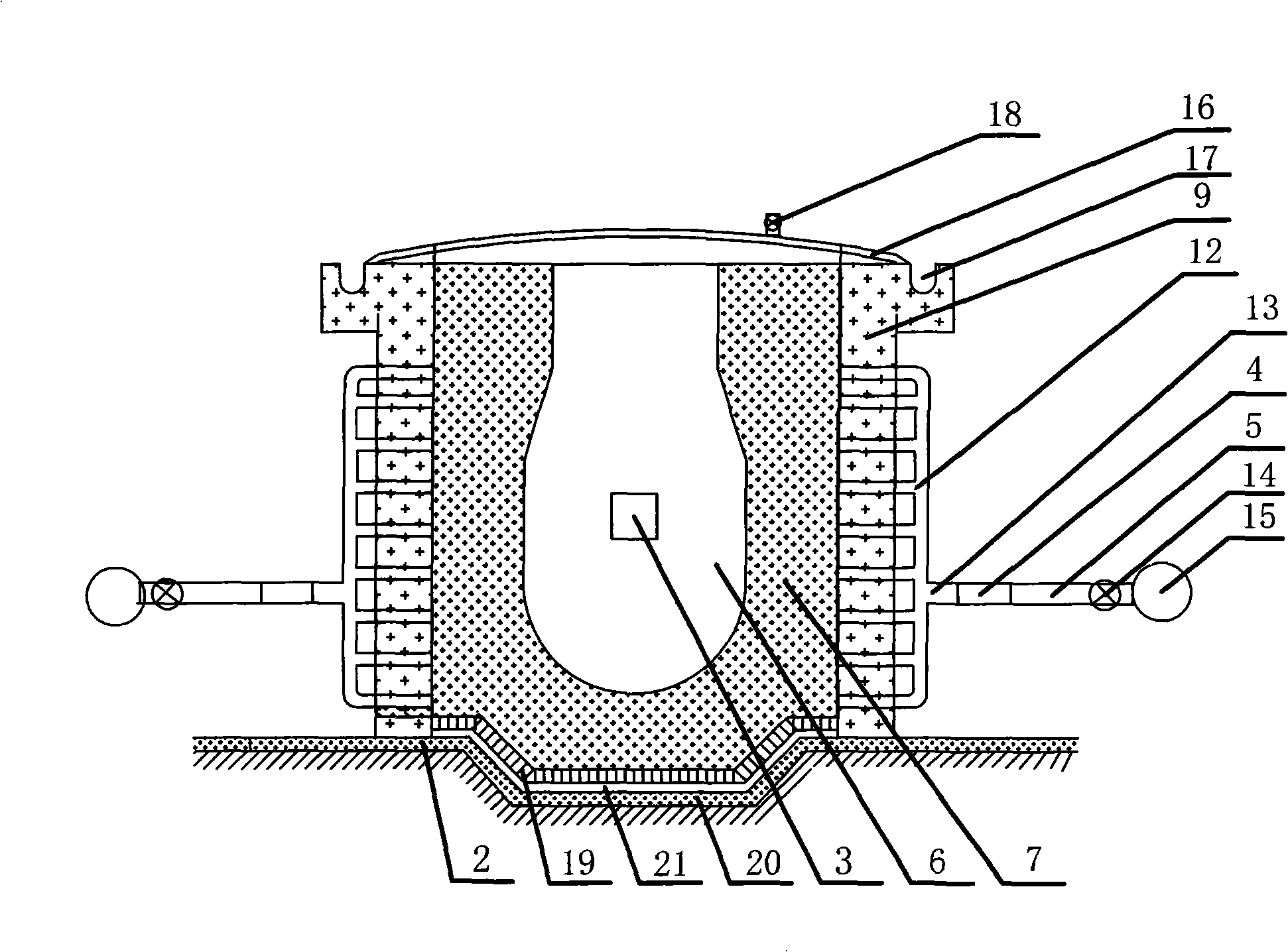

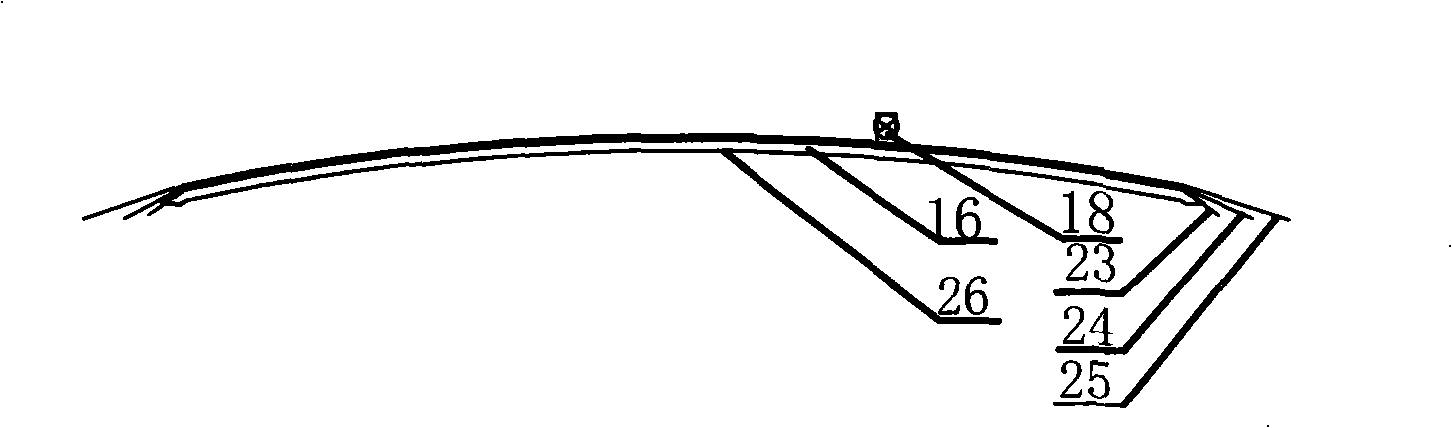

[0025] like figure 1 , 4 As shown in , 5, the body of the silicon carbide smelting furnace is composed of a furnace head 1, a furnace bottom 2, and an electrode 3. Airtight furnace walls 9 are arranged on both sides of the furnace body, and the furnace wall 9 is formed directly with the furnace head 1 and the furnace bottom 2. Groove shape, on which a furnace cover 16 is arranged, the furnace cover 16 is composed of asbestos cloth layer 23 to form the inner layer, canvas layer 24 to form the middle layer, rainproof cloth or plastic cloth 25 to form the outer layer, and the inner, middle and outer layers are fixed on the support frame On 26, form a rectangular lid, just cover on the body of heater, furnace lid 16 tops are provided with breathable valve 18.

[0026] Furnace wall 9 and burner head 1 top are provided with annular groove 17, as shown in Figure 5 top view, furnace cover 16 is covered on the body of furnace, and edge just puts into annular groove 17, and with quartz...

Embodiment 2

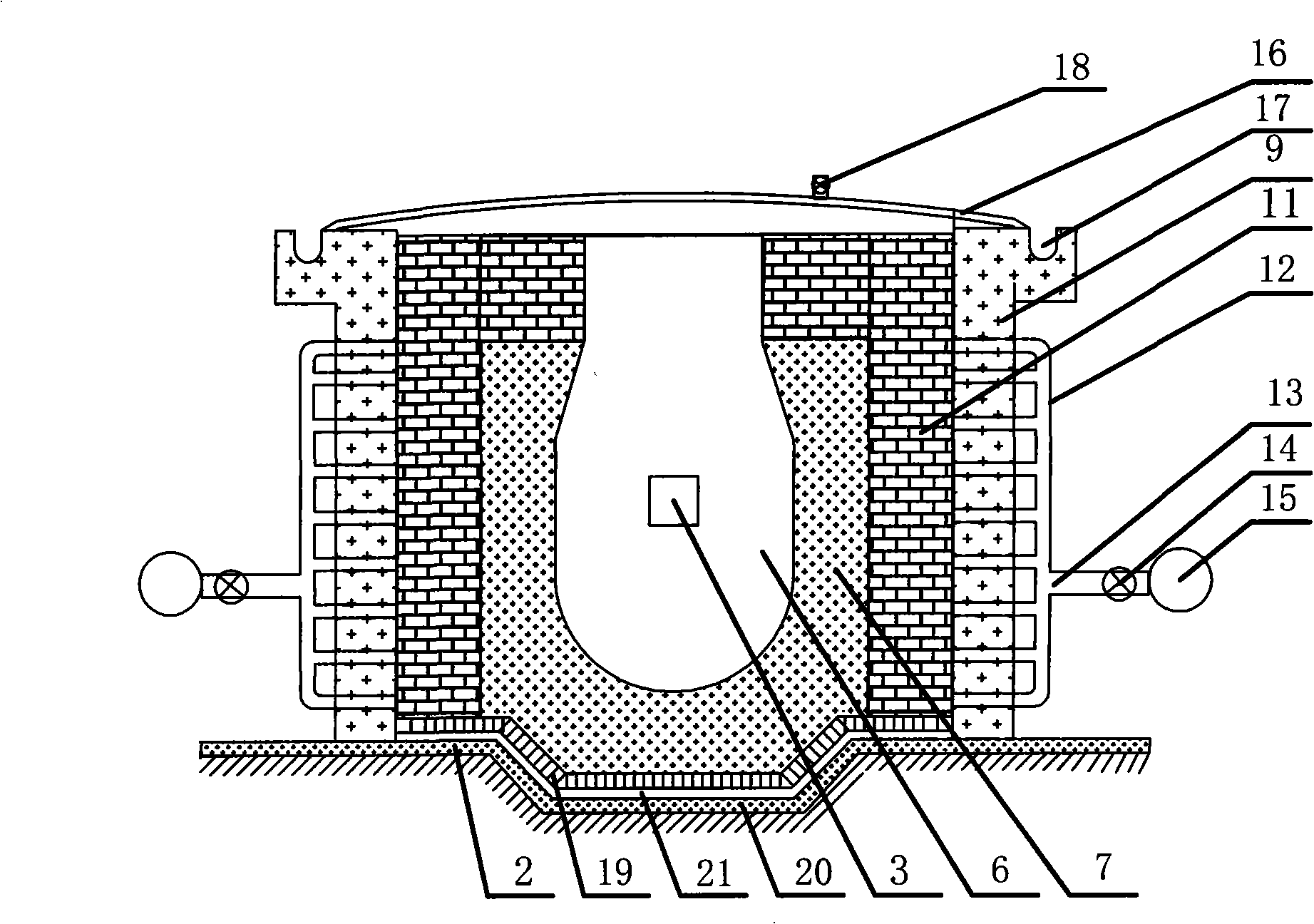

[0029] like figure 2 , 4 , 6, this silicon carbide smelting furnace, body of furnace is made up of burner head 1, furnace bottom 2, electrode 3, airtight furnace wall 9 is arranged on both sides of furnace body, and the inner side of furnace wall 9 is provided with breathable heat insulation layer 11, As shown in the top view of Figure 6, the heat insulation layer 11 is made up of multiple heat insulation layers, and the number of pieces is adjustable according to the length of the furnace. Each piece has a length of 3 meters. The width of the heat layer is 0.5 meters, the purpose is to separate the heat of the reaction space, avoid heat loss and heat radiation to the furnace wall and external pipes.

[0030] The furnace wall 9 forms a straight groove with the furnace head 1 and the furnace bottom 2, and a furnace cover 16 is arranged on it. The furnace cover 16 is composed of an asbestos cloth layer 23 as an inner layer, a canvas layer 24 as an intermediate layer, and a rai...

Embodiment 3

[0034] like image 3 , 4 , 7, the silicon carbide smelting furnace, the furnace body is composed of a furnace head 1, a furnace bottom 2, and an electrode 3, and an airtight furnace wall 9 is arranged on both sides of the furnace body, and an inner furnace wall 8 is arranged on the inner side of the furnace wall 9, and the inner furnace wall 8 is a ventilation furnace wall, and there is a space between the furnace wall 9 and the inner furnace wall 8 to form a gas collection chamber 10. Inner furnace wall 8 inboards are provided with air-permeable heat insulation layer 11, as shown in Fig. 7 top view, heat insulation layer 11 is made up of many heat insulation layers, and block number is adjustable according to furnace length, and each length is 2 meters, and every block The heat layer can be moved to facilitate disassembly and assembly. The width of each heat insulation layer is 3 meters. The purpose is to separate the heat of the reaction space, avoid heat loss and heat radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com