Enclosure pipeline-type stator evaporating and cooling device

An evaporative cooling, pipeline technology, applied in the direction of cooling/ventilation device, electromechanical device, casing/housing/support, etc. The effect of reducing the number of joints, good cooling effect, and high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

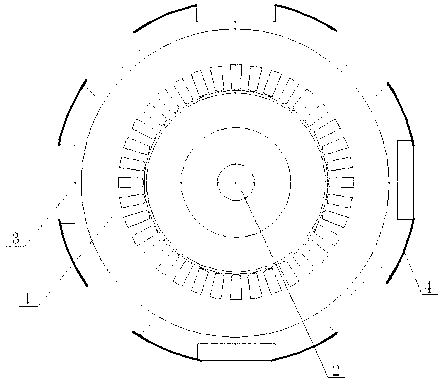

[0023] The content of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0024] The stator evaporative cooling device of the present invention has two implementation modes of self-circulation and forced circulation.

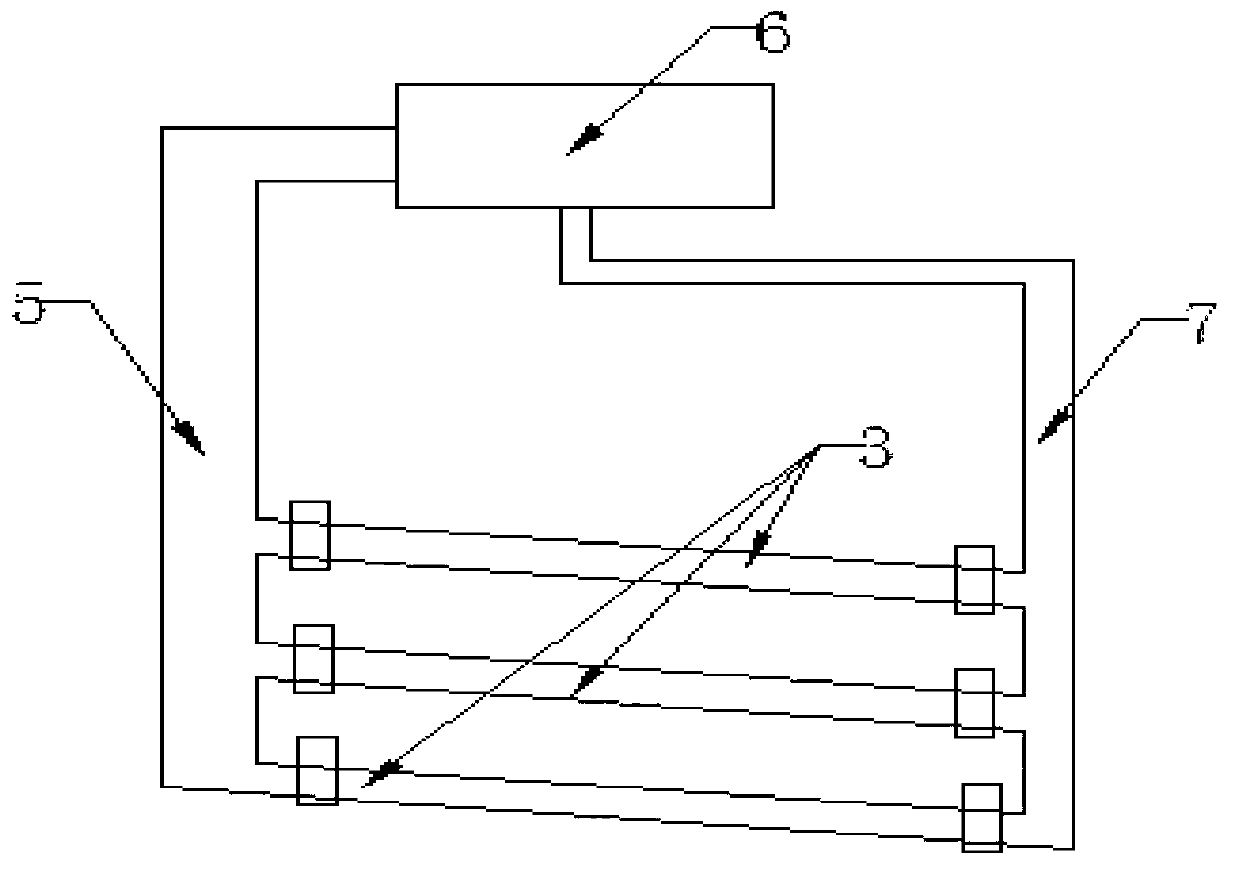

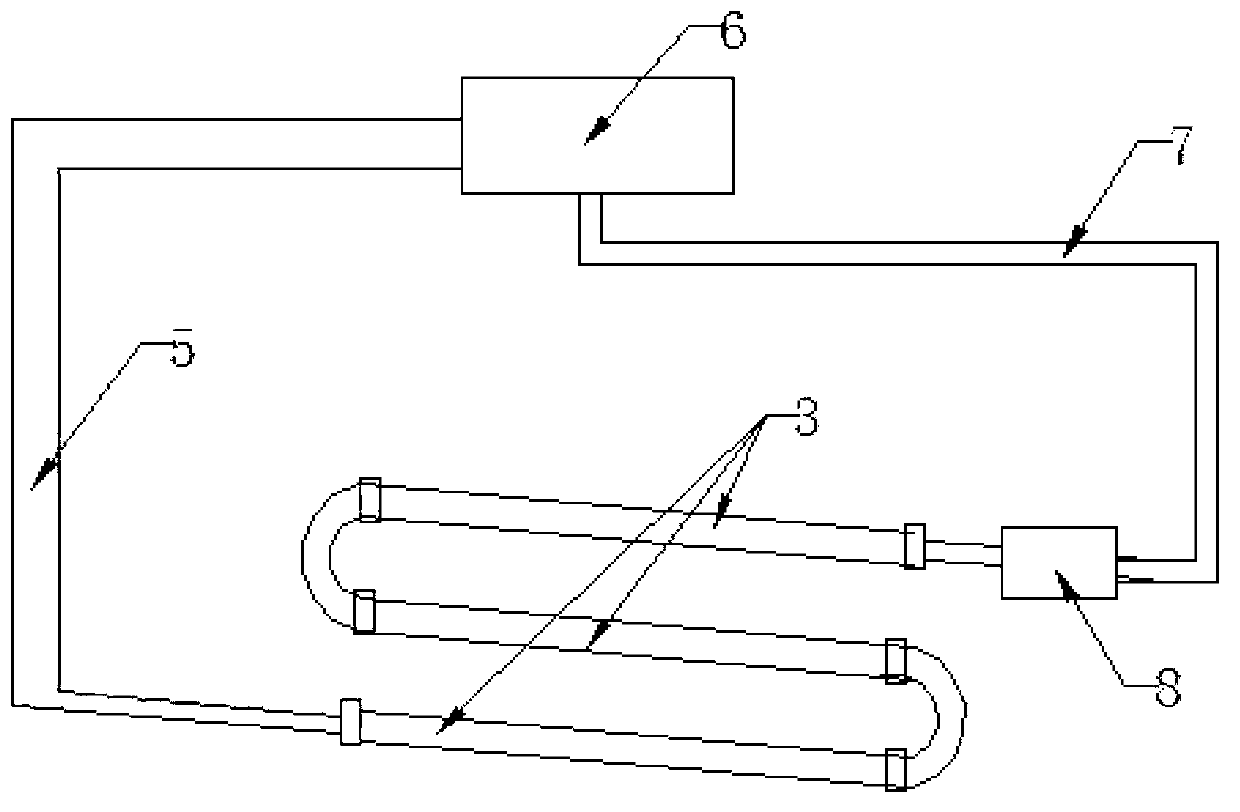

[0025] figure 1 Shown is an example of self-circulation. The self-circulating stator evaporative cooling device of the present invention includes a cooling pipeline 3 , an air collecting pipe 5 , a condenser 6 and a liquid return pipe 7 . In order to achieve self-circulation, the condenser 6 is installed at a certain height above the motor; one end of the air collecting pipe 5 is connected to the outlet of the cooling pipeline 3, and the other end of the air collecting pipe 5 communicates with the condenser 6; one end of the liquid return pipe 7 is connected to the condenser 6. The other end of the liquid return pipe 7 is connected to the inlet of the cooling pipeline 3 . The inside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com