Multi-phase internal circulating anaerobic reactor

An anaerobic reactor, anaerobic reaction technology, applied in anaerobic digestion treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of reduced treatment efficiency, how to evenly distribute influent water, etc., to maintain activity and convenience Combination and expansion, the effect of good sludge interception performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further illustrate the present invention, below in conjunction with embodiment is described in more detail.

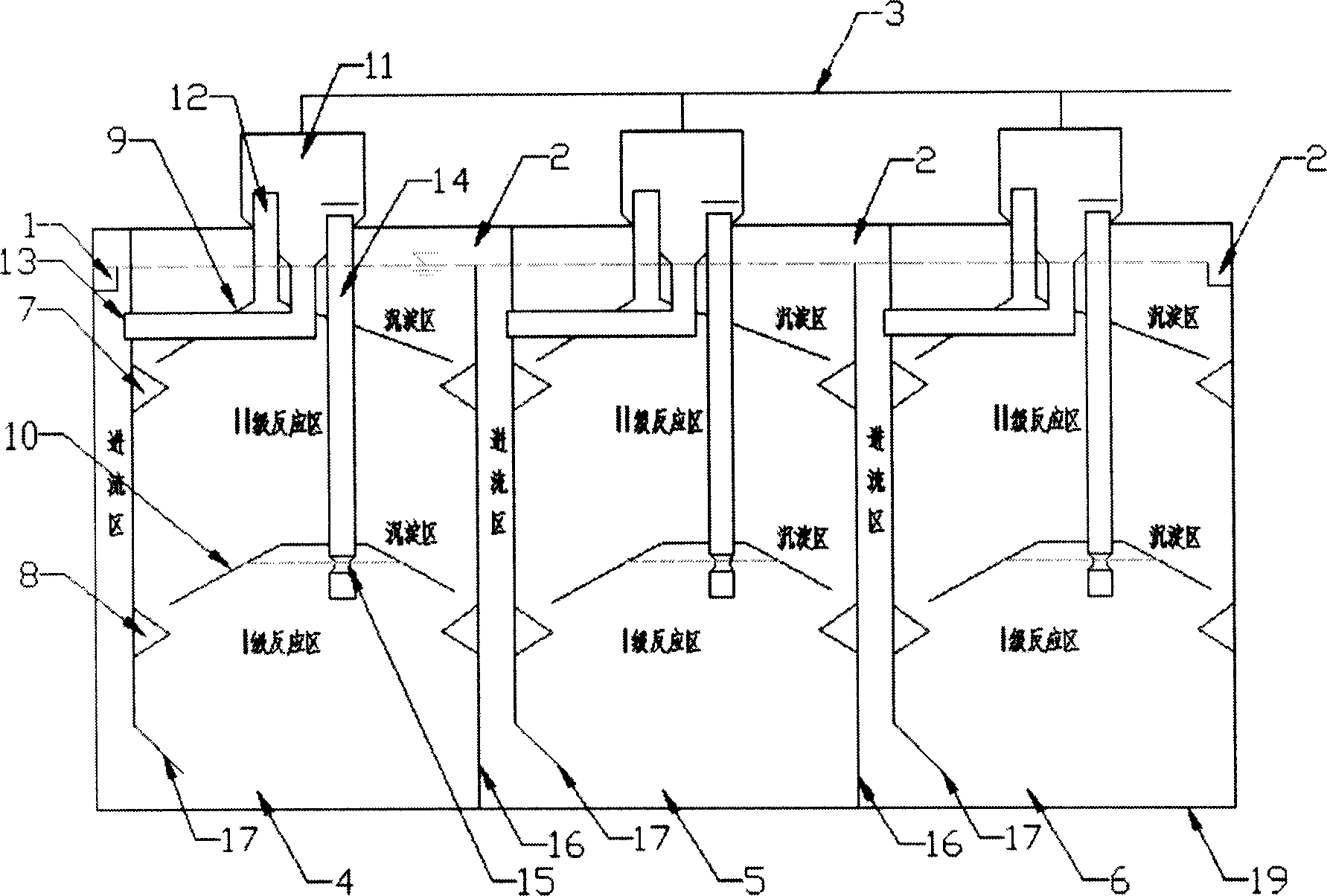

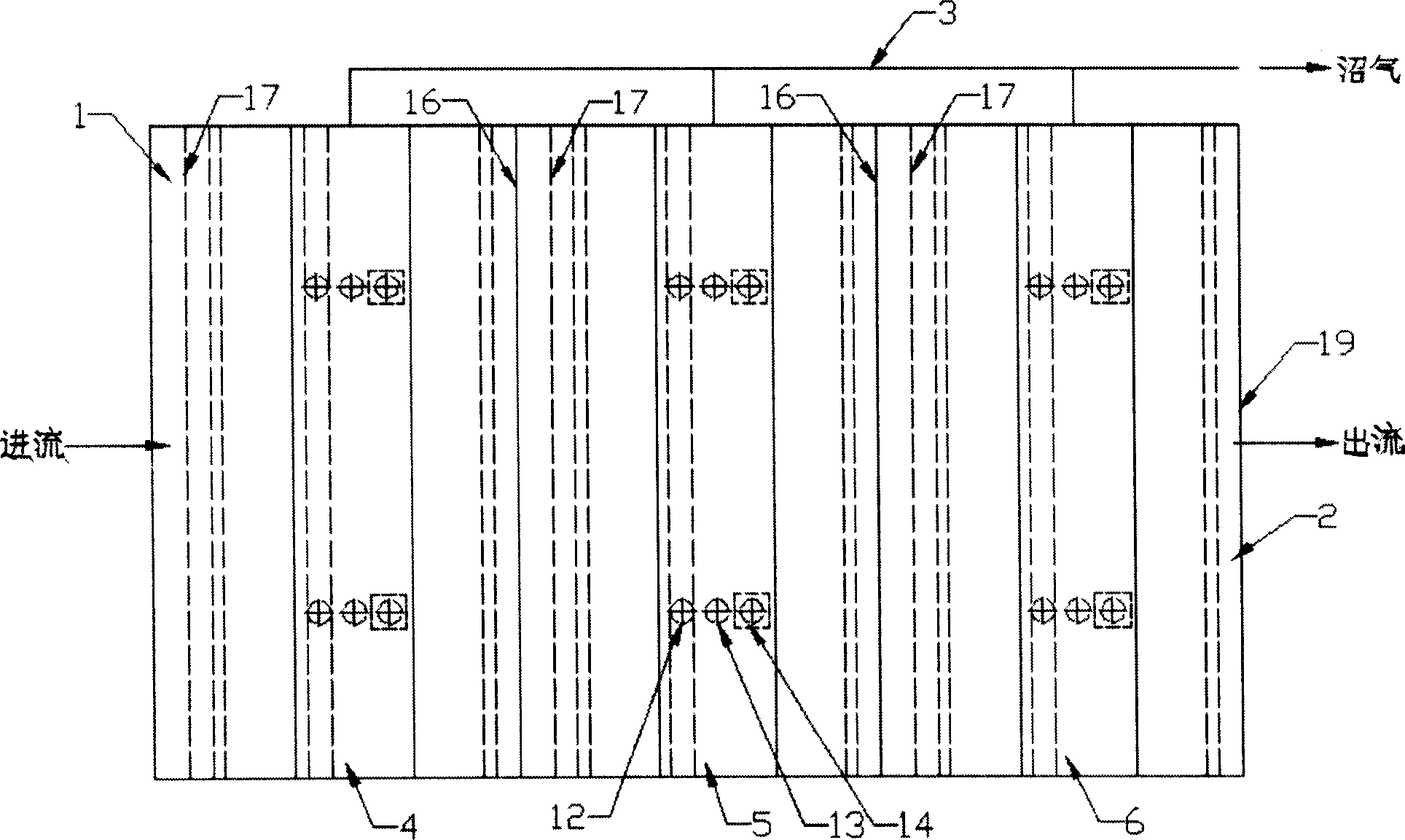

[0016] figure 1 It is a schematic diagram of an embodiment of the heterogeneous internal circulation anaerobic reactor of the present invention. Multiphase internal circulation anaerobic reactor pool body 19 is divided into three internal circulation anaerobic reaction chambers 4, 5, 6 with two partition walls 16, and the structure of three single internal circulation anaerobic reaction chambers is the same, for An internal circulation anaerobic reaction chamber with a secondary reaction zone (hereinafter referred to as the reaction chamber).

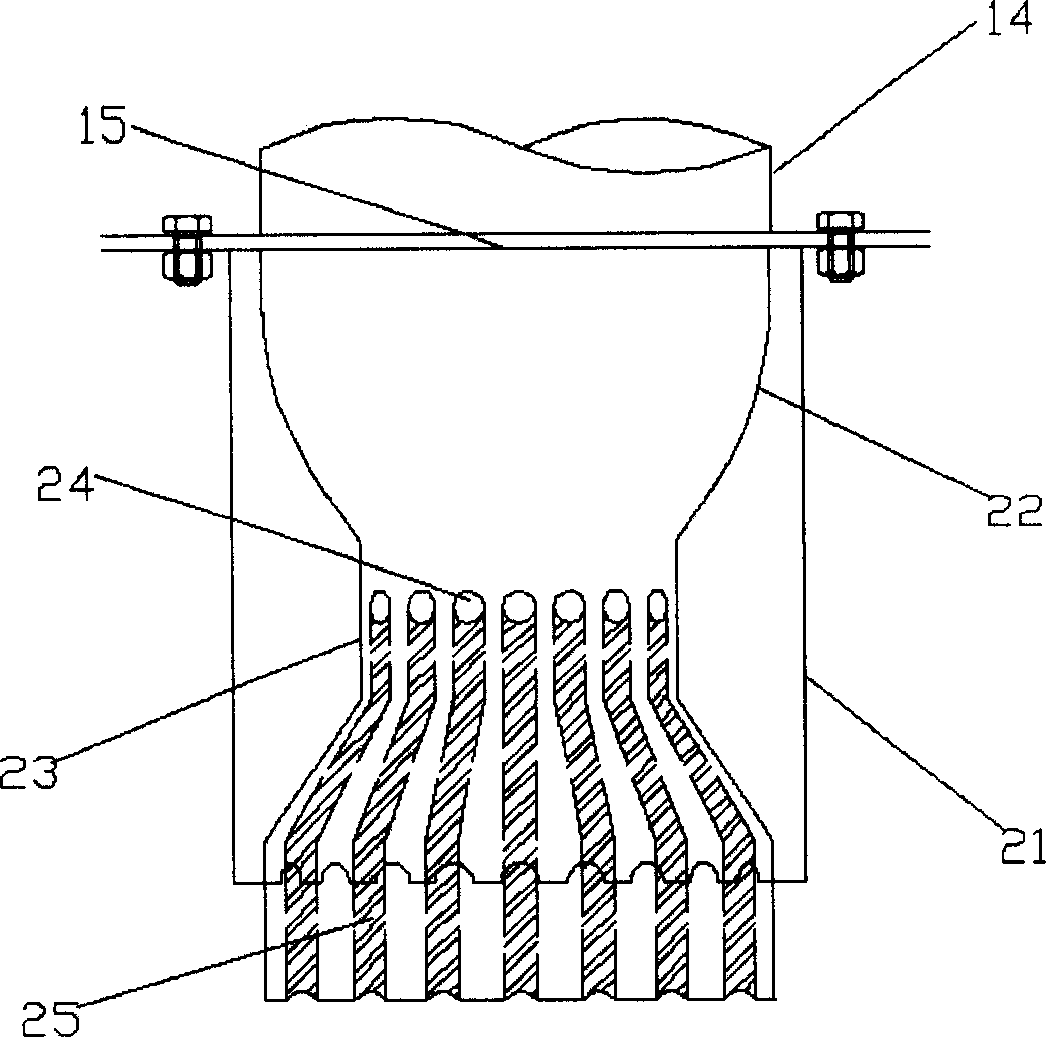

[0017] In each reaction chamber, two three-phase separators 10, 9 are provided to form the lower I-level reaction zone and the upper II-level reaction zone respectively, and on the slopes of the two three-phase separators 10, 9, a Two settling areas, the gas collection pipe 12 is connected to the three-phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com