Hollow fiber forward osmosis composite membrane containing oriented carbon nanotubes and preparation method thereof

A technology of carbon nanotubes and composite membranes, applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems that it is difficult to give full play to the transmission function of carbon nanotube molecular channels, and achieve excellent separation characteristics and high density , Improve the effect of salt rejection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

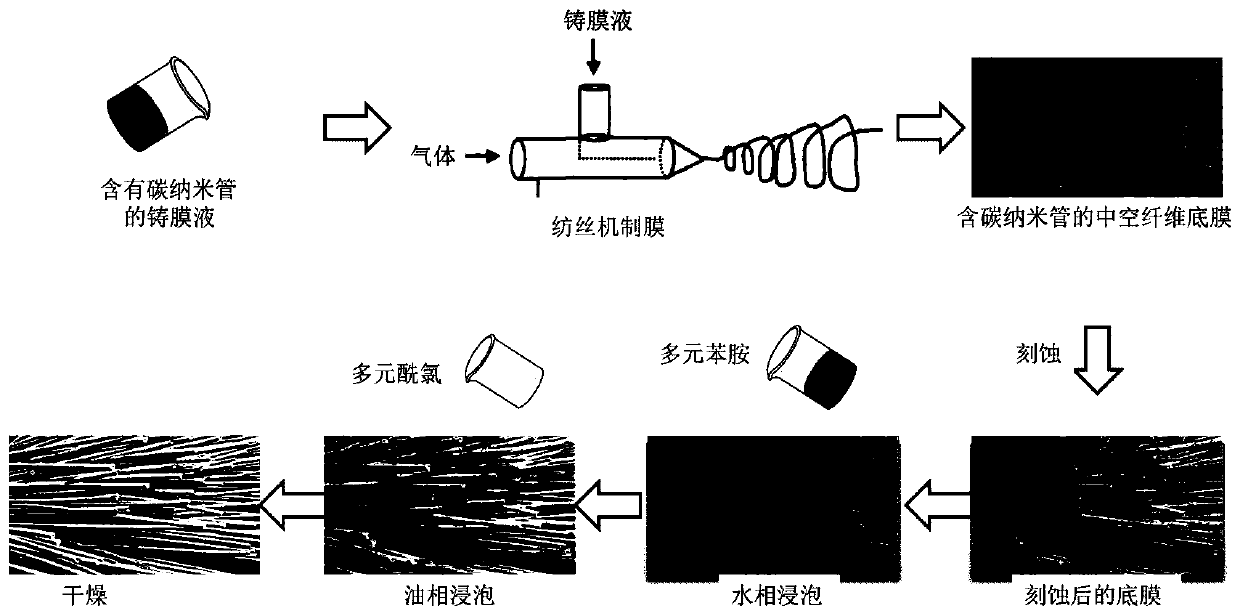

[0046] This embodiment provides a kind of preparation method that contains 1% (wt) oriented carbon nanotube hollow fiber membrane, and the operation process is as follows figure 1 As shown, the specific steps are as follows:

[0047] (1) Disperse 0.2g acidified multi-walled carbon nanotubes in 80g N-N dimethylformamide, disperse evenly after ultrasonic 2h, add 1g polyvinylpyrrolidone (weight average molecular weight is 2000) and 18.8g polysulfone (weight-average molecular weight is 30000), after stirring 4h, forms uniform casting solution;

[0048] (2) Pour the casting solution into the still of the spinning machine, seal the still of the spinning machine, heat the still of the spinning machine so that the temperature of the spinning material liquid is at 25° C., and perform vacuum degassing treatment for 30 minutes. After the degassing treatment of the spinning material liquid, open the outlet switch of the kettle, feed nitrogen into the kettle to pressurize, turn on the swi...

Embodiment 2-4

[0052] Only changing the content of modified carbon nanotubes to 0.05g, 0.5g and 1g, the amount of polysulfone correspondingly becomes 18.95g, 18.5g, 18g, other operations are the same as in Example 1, and the densities of the obtained aligned carbon nanotubes are respectively averaged 1, 3.2, and 4.5 per square micron, and the forward osmosis characteristics of the obtained hollow fiber composite membrane were measured, and the results are shown in Table 1.

Embodiment 5

[0054] The implementation is the same as in Example 1, only the type of carbon nanotubes is changed, and the acidified single-walled carbon nanotubes are selected. The density of the obtained oriented carbon nanotubes is respectively averaged at 2.9 per square micron, and the forward osmosis of the obtained hollow fiber composite membrane is measured. properties, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com