Oil-gas-water three-phase hypergravity separator

A technology of oil-water separator and gas-liquid separator, which is applied in the field of three-phase separation, can solve the problems of large volume, large area and fast settling speed of the three-phase separator, and achieves light weight, small area and high maintenance. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

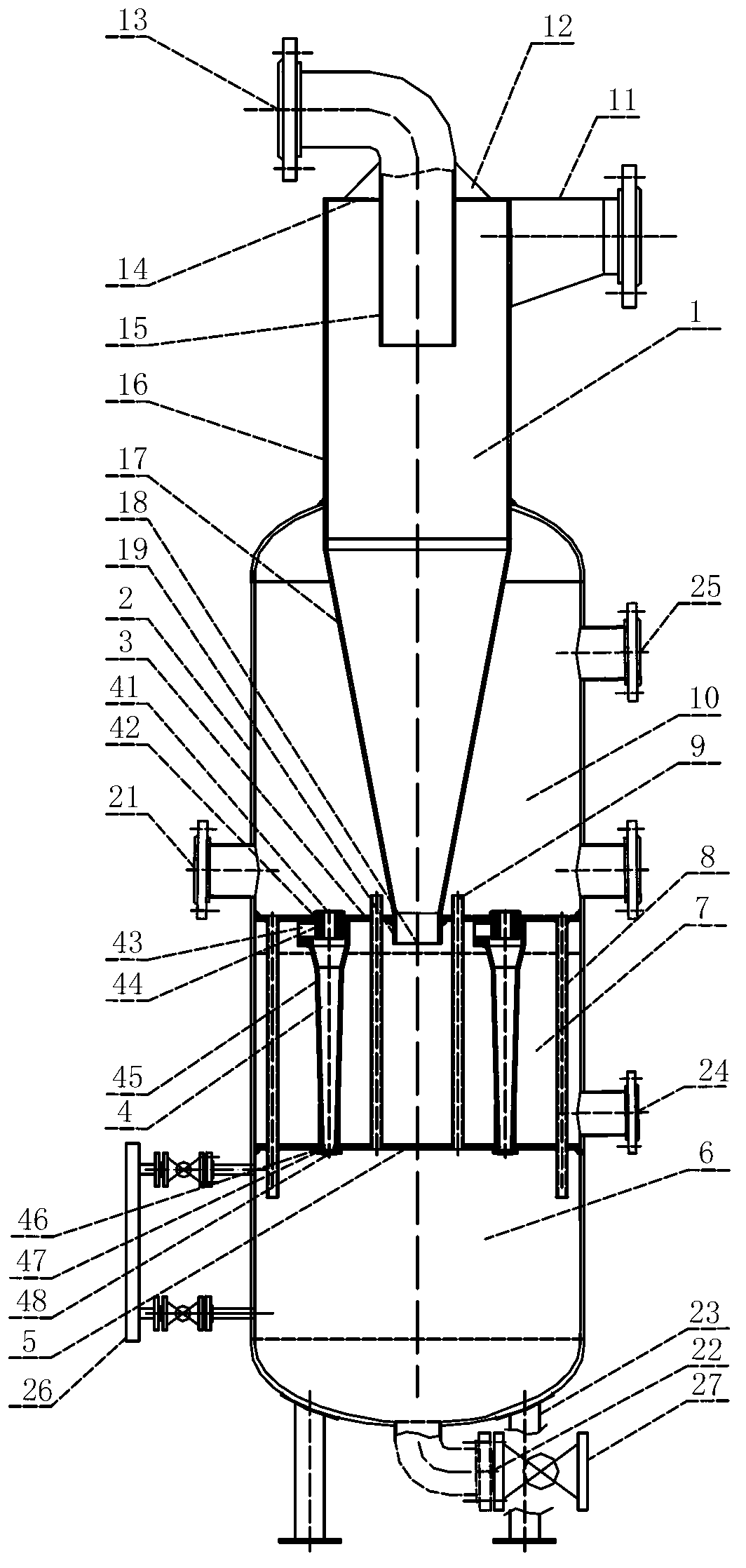

[0033] It includes a casing 2, one or more gas-liquid separators 1, one or more oil-water separators 4, a set of return pipes 8, a set of oil return pipes 9 and an oil-water interface controller 26, characterized in that: the gas The liquid separator 1 is a cyclone supergravity gas-liquid separator, which has an inlet pipe 11, an exhaust port 13 and a liquid discharge port 18;

[0034] The oil-water separator 4 is a swirl type supergravity oil-water separator, which has an oil discharge port 41, an oil-water inlet 43 and a drain port 48;

[0035] The shell 2 is separated into a water collection chamber 6, an oil-water chamber 7 and an oil collection chamber 10 from bottom to top by a lower partition 5 and an upper partition 3. An oil-water interface controller 26 is installed on the side of the water collection chamber 6, and an oil-water interface controller 26 is installed on the bottom of the water collection chamber. Outrigger 23;

[0036] The gas-liquid separator 1 is inse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com