Solid-liquid separator suitable for kitchen waste

A technology for solid-liquid separation and kitchen waste, applied in liquid separation, separation methods, centrifuges with rotating drums, etc. The effect of small amount, reduction of environmental impact and loss of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

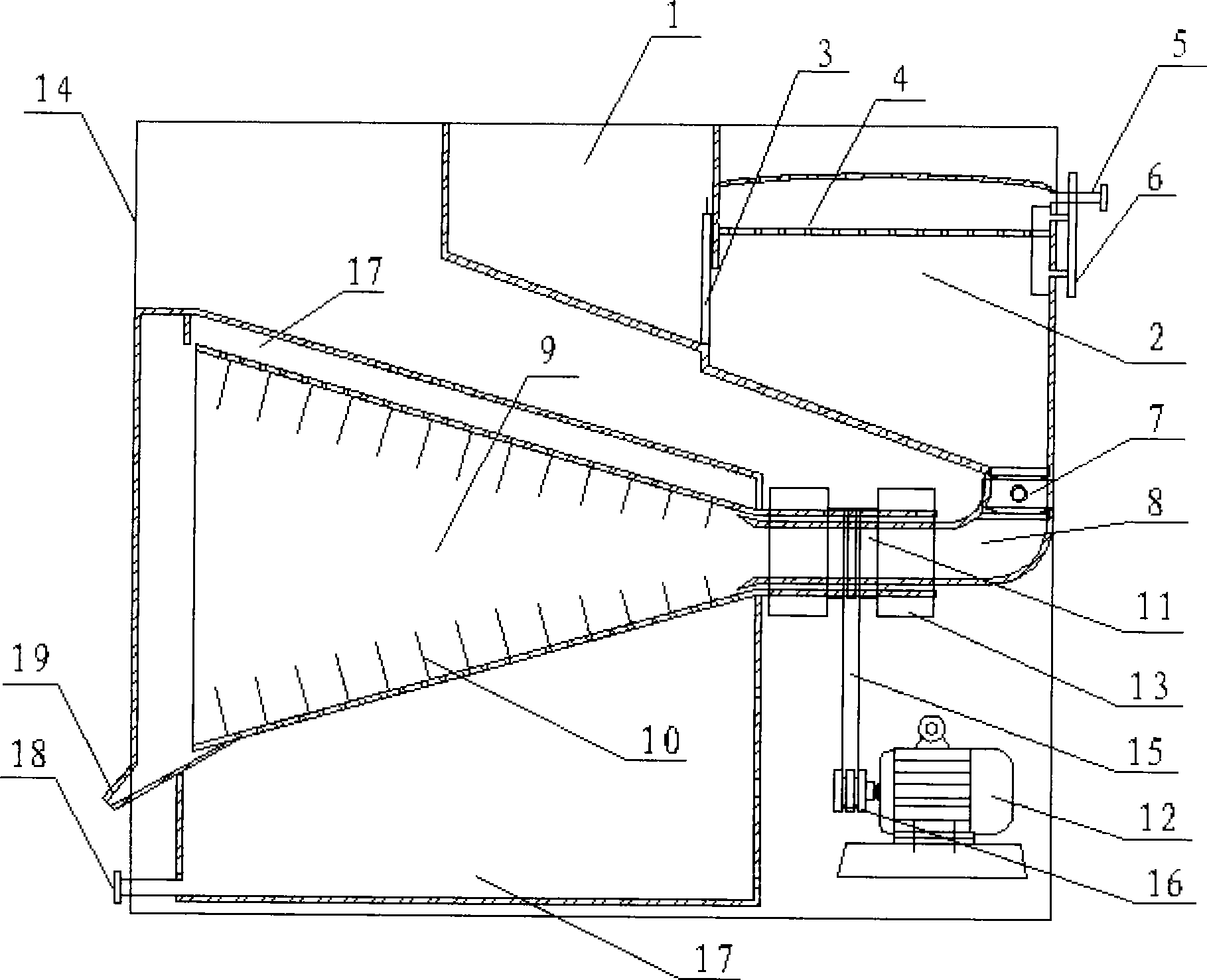

[0014] Embodiment 1: as figure 1 As shown, the food waste solid-liquid separation device is fed by the feeding cylinder 1, and then the material flows into the oil-water separator 2. There is a first valve 3 between the feeding cylinder and the oil-water separator 2, which is used to adjust the feed flow. The oil-water separator is provided with an oil decanter 4, an oil guide pipe 5 and a liquid level observer 6, and the oil decanter 4 is a thin plate drilled with uniform through holes. The liquid level of the material in the oil-water separator can be observed through the liquid level observer 6. When reaching a certain height, the grease floating on the liquid surface of the material surface is collected through the oil decanter 4 through the oil guide pipe 5. The rest of the material enters the solid-liquid separation drum 9 through the second valve 7 and the pipeline 8. The wall of the solid-liquid separation drum 9 is drilled with through holes, and a plurality of liftin...

Embodiment 2

[0015] Embodiment 2: It is composed of feeding cylinder 1, oil-water separator 2, solid-liquid separation drum 9, liquid storage tank 17, transmission device and other accessories, and uses the principle of connecting device and centrifugal principle to effectively separate food waste into oil and water and solid matter.

[0016] The oil-water separator 2 is a double-layer closed structure, the upper layer is provided with a horizontal oil decanter 4 and a liquid level observer 6, and grease is discharged through the oil decanter 4 through the oil guide pipe 5.

[0017] The oil decanter 4 in the oil-water separator 2 is a thin plate drilled with uniform through holes.

[0018] The solid-liquid separation drum 9 is a horizontal trumpet-shaped structure, the drum wall has uniform through holes, and a number of lifting plates are fixed on the inner wall.

[0019] The solid-liquid separation drum 9 can rotate at a high speed driven by the motor 12 and the second pulley 11 to dehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com