Method for recovering organic waste gas

A technology for organic waste gas and recovery methods, applied in separation methods, chemical instruments and methods, steam condensation, etc., can solve problems such as secondary pollution, high cost of wastewater reprocessing, and reduced recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

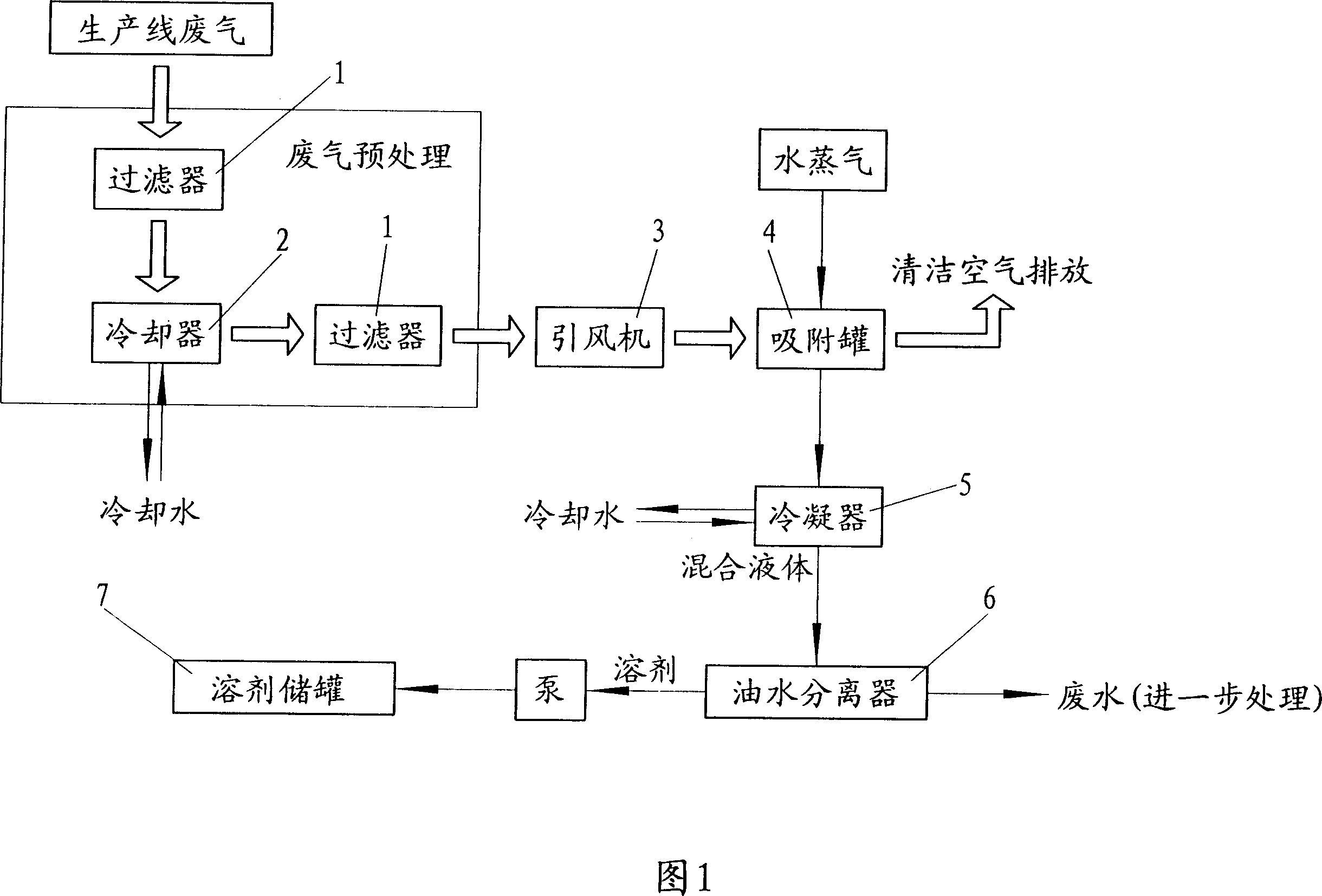

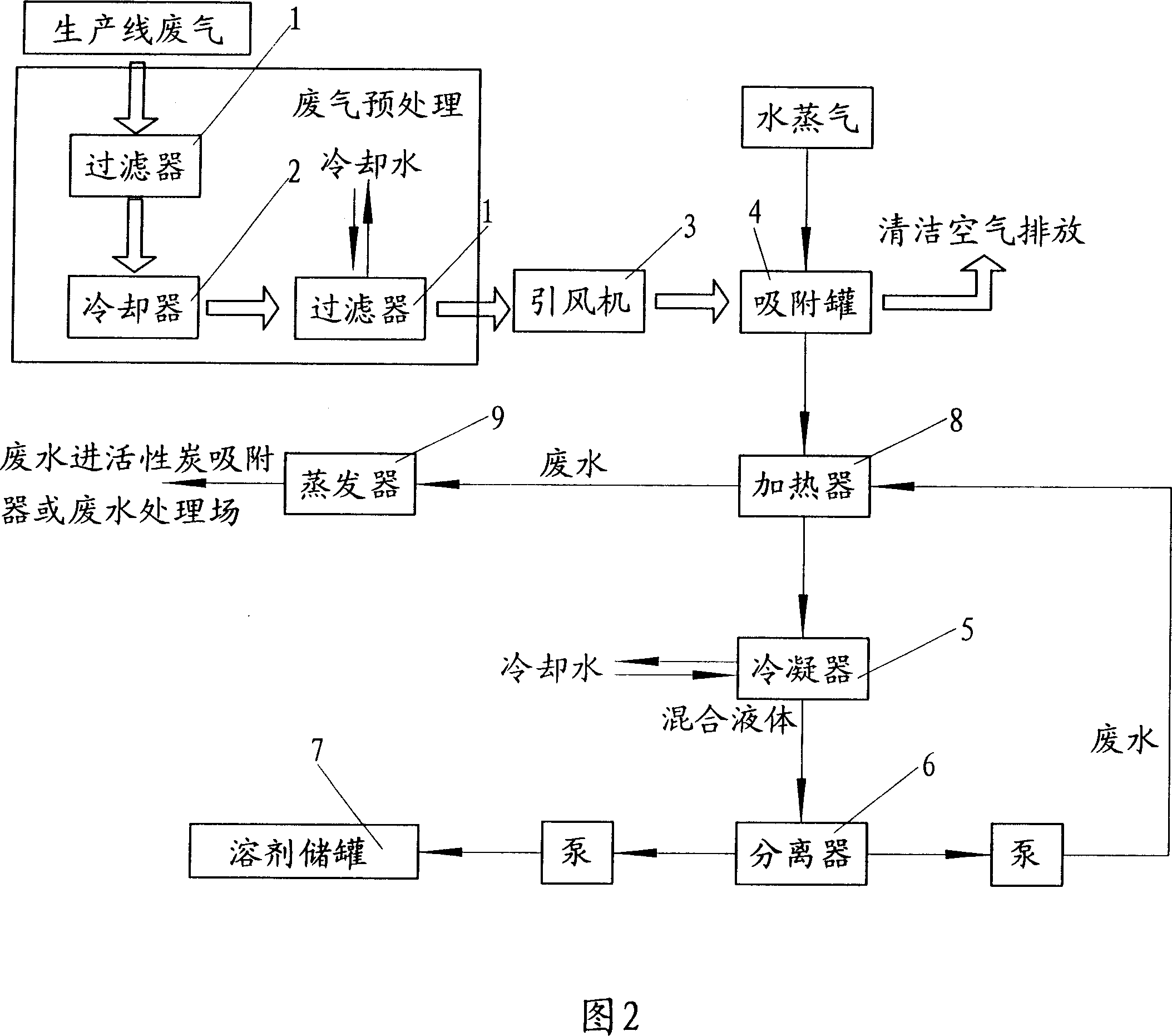

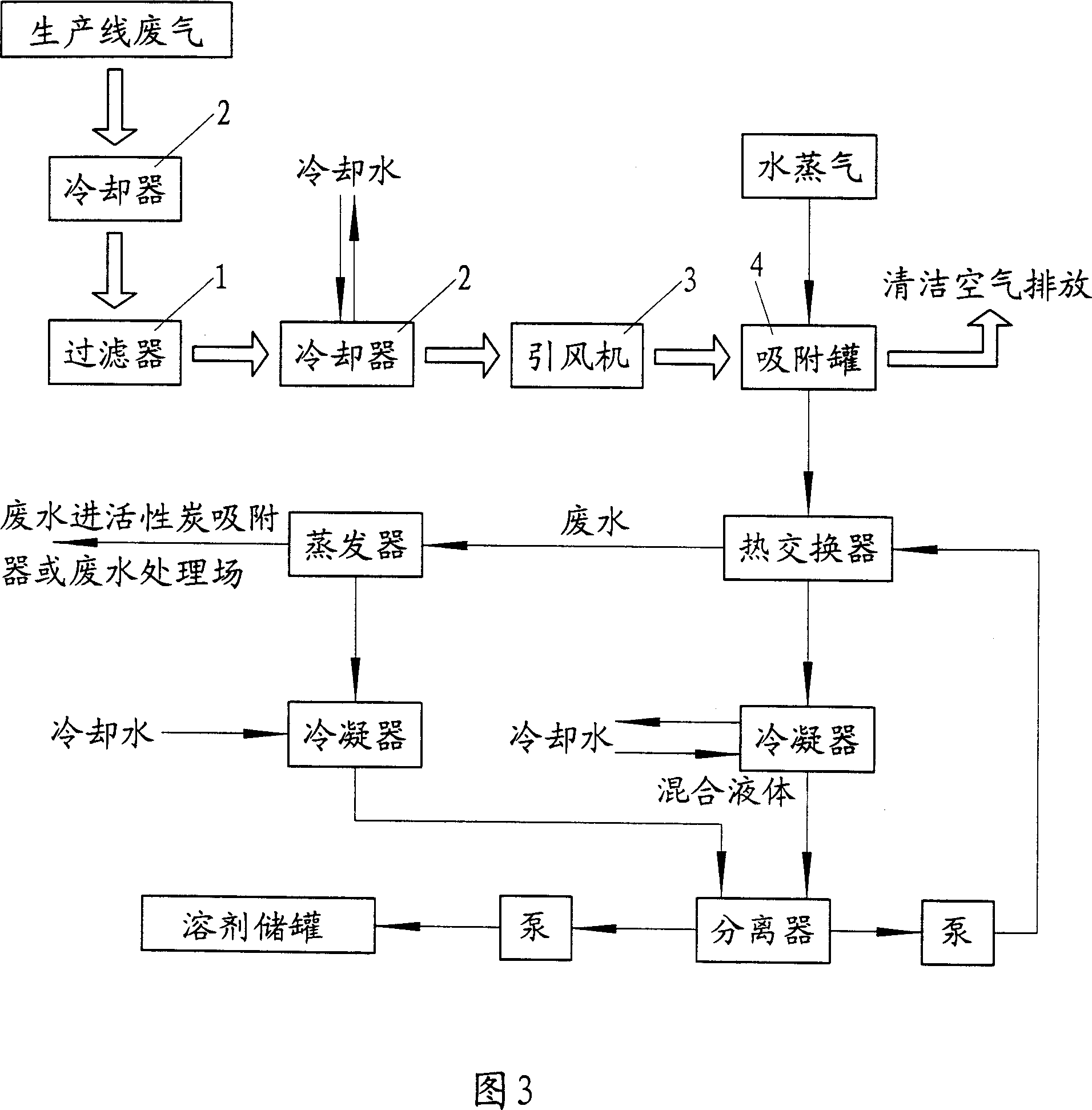

[0017] As shown in Figure 2, it is the first embodiment of the organic waste gas recovery method disclosed by the present invention. The organic waste gas is first pretreated by the filter 1 and the cooler 2 (or through the filter 1 again), and then enters through the induced draft fan 3 The adsorption tank 4 performs adsorption, and after the adsorption is saturated, the mixed gas is desorbed and regenerated with water vapor, and the desorbed mixed gas is condensed by the condenser 5, and then enters the oil-water separator 6 to separate the solvent and waste water. The improvement of the present invention is to add a partition heat exchange wastewater heater 8 after the adsorption tank 4 and before the condenser 5; The residual heat of the water vapor is heated through the heat exchange between the partition walls, and after heating to 2-10 °C above the boiling point or azeotropic point of the organic solvent, the organic solvent is fully evaporated, and the residual solvent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com