Manufacturing method of heat increasing and component controlling briquette used in steel manufacturing process

A manufacturing process and component control technology, applied in chemical instruments and methods, improvement of process efficiency, crystal growth, etc., can solve the problems of fire, high price, dependence on imports, etc., and achieve the effect of preventing broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. In the following description of the present invention, a detailed description of known functions and configurations incorporated herein will be omitted when it may obscure the subject matter of the present invention.

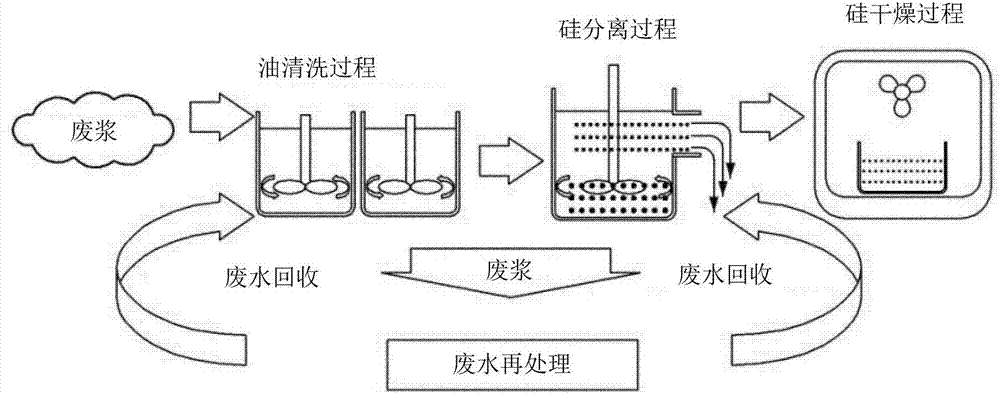

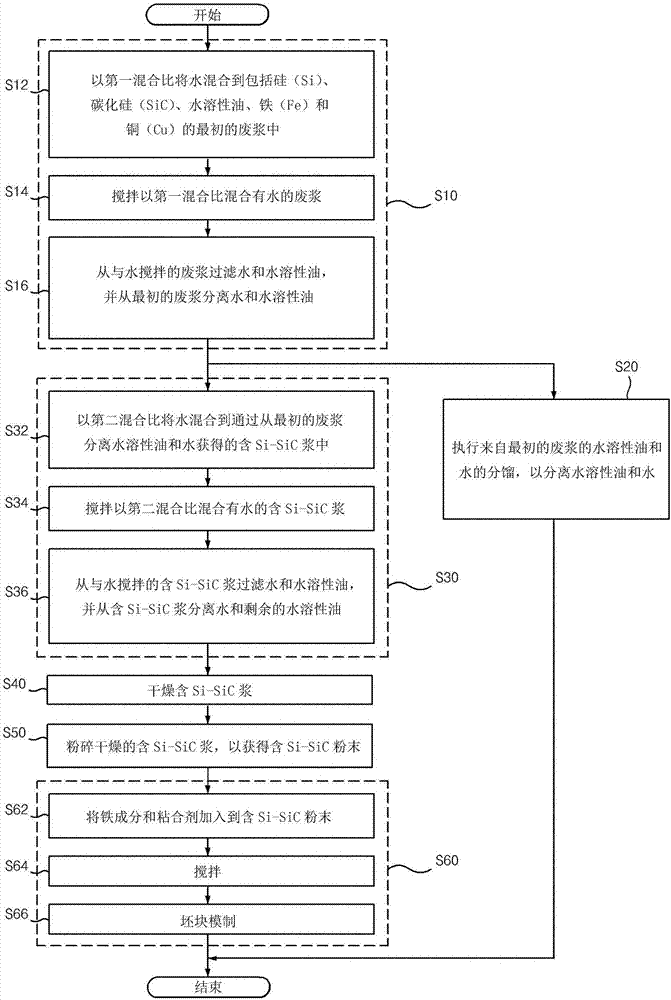

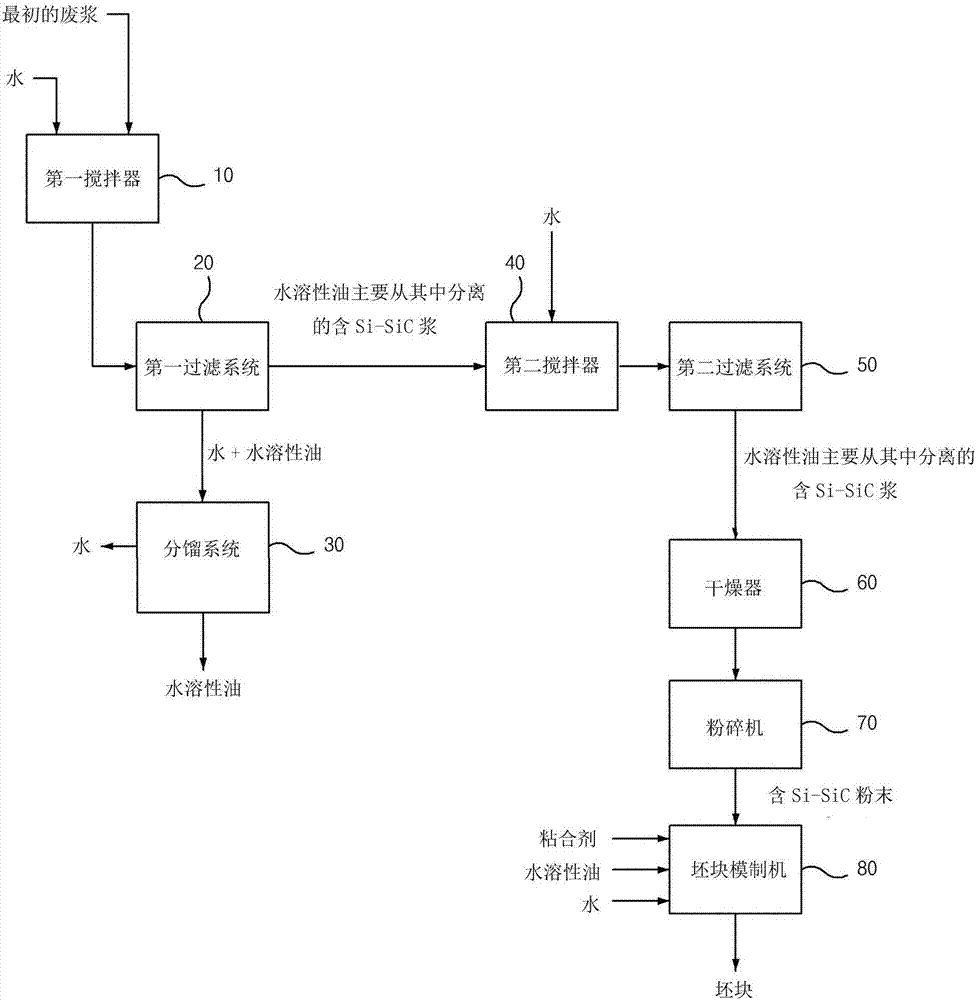

[0073] figure 1 It is a diagram conceptually showing a process of purifying silicon-containing waste slurry discharged as a by-product in the process of manufacturing semiconductor or solar cell wafers.

[0074] see figure 1 First, slicing materials, silicon sawdust, slicing oil, and other materials such as slicing materials generated during slicing or fine powder of wire saws are involved in the slicing process of silicon ingots or the surface polishing process of silicon wafers.

[0075] As shown, an oil washing process is provided in order to separate silicon and chip material that may be recovered from this spent slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com