Comprehensive treatment method and system for benzene chloride waste liquid

A technology for comprehensive treatment and chlorination of benzene, applied in chemical instruments and methods, chlorine/hydrogen chloride, water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

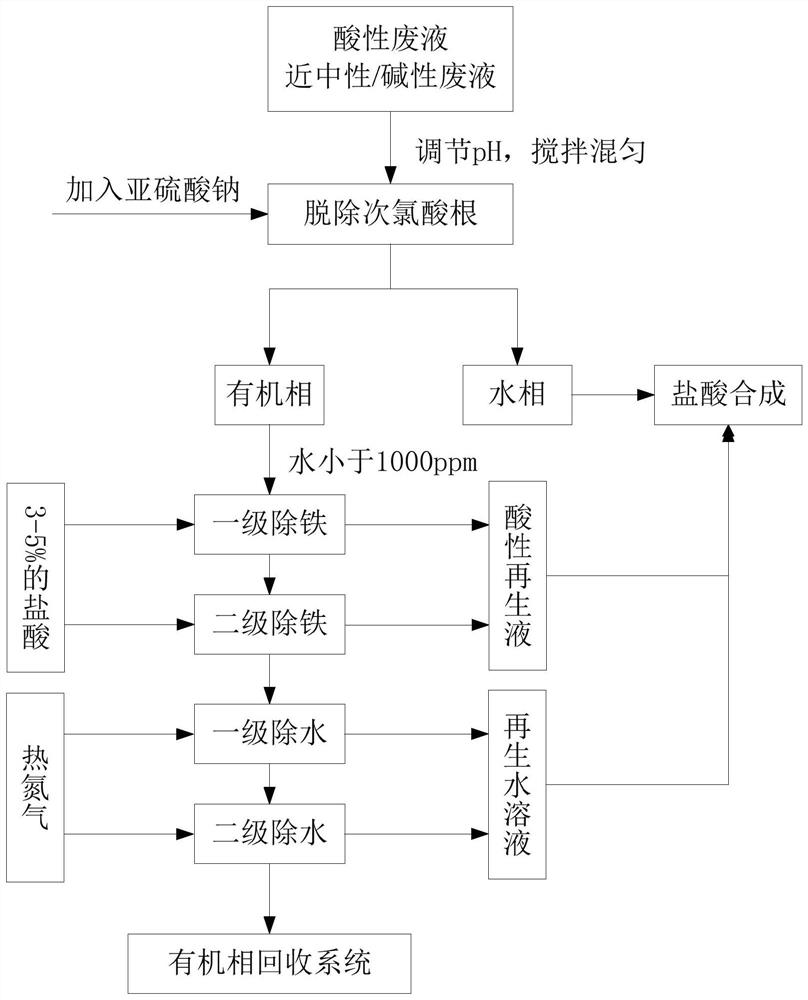

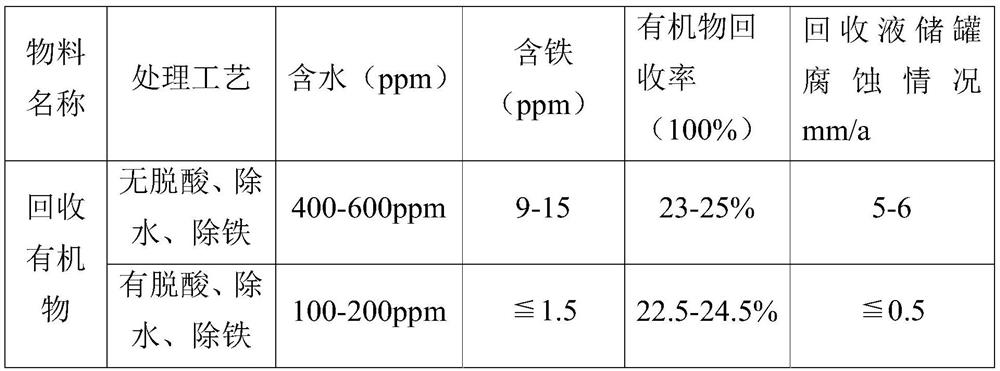

[0059] Embodiment 1: refer to simultaneously figure 1 and figure 2

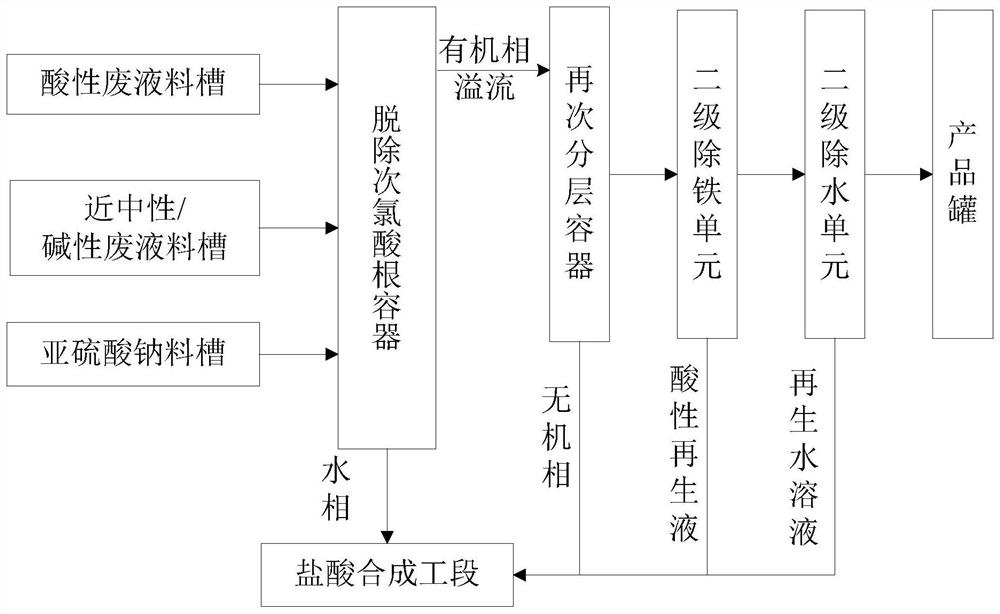

[0060] Such as figure 2 As shown, the comprehensive treatment and recycling system of chlorinated benzene waste liquid of the present invention includes an acidic waste liquid trough for containing the acidic waste liquid produced in the concentrated collection of chlorinated benzene production process; The near-neutral / alkaline waste liquid hopper of the near-neutral / alkaline waste liquid produced in the collected chlorinated benzene production process; A hypochlorite removal container connected to a near-neutral / alkaline waste liquid trough for the removal of hypochlorite in the waste liquid; a device for stratifying the organic phase after the reaction in the hypochlorite removal container is completed Layered container again; Iron removal unit, removes iron from the organic phase obtained by layering the layered container again; Water removal unit I, removes water from the organic phase after iron re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com