Industrialized treatment facility and method for catering wastes

A technology of catering waste and treatment facilities, which is applied in the field of industrial separation, pollution control and recycling facilities, can solve the problems of incomplete decomposition, incomplete oil-water separation, inability to digest waste oil, etc., and achieve the effect of solving secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

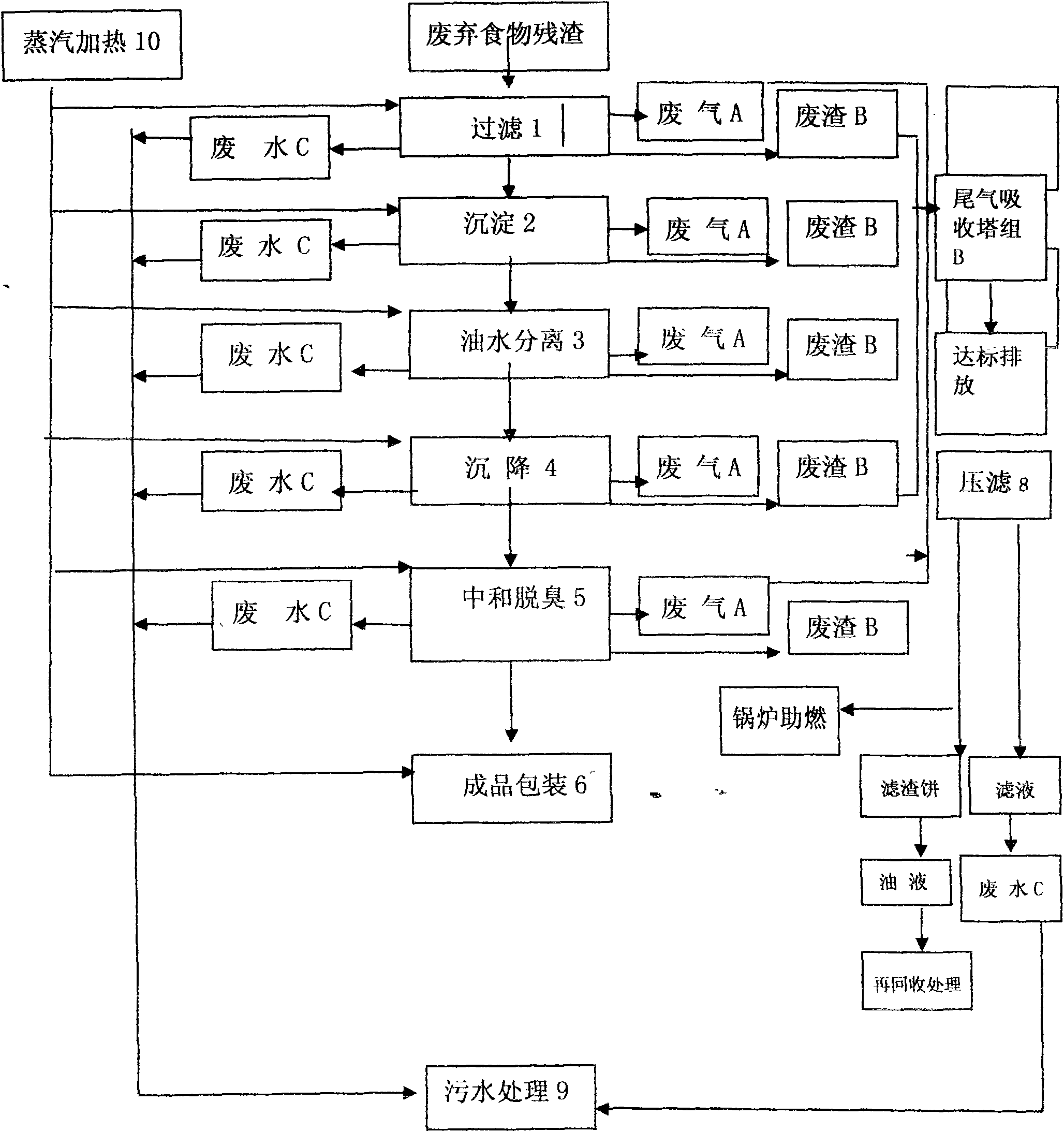

[0025] An embodiment is described below in conjunction with the accompanying drawings to further illustrate the present invention.

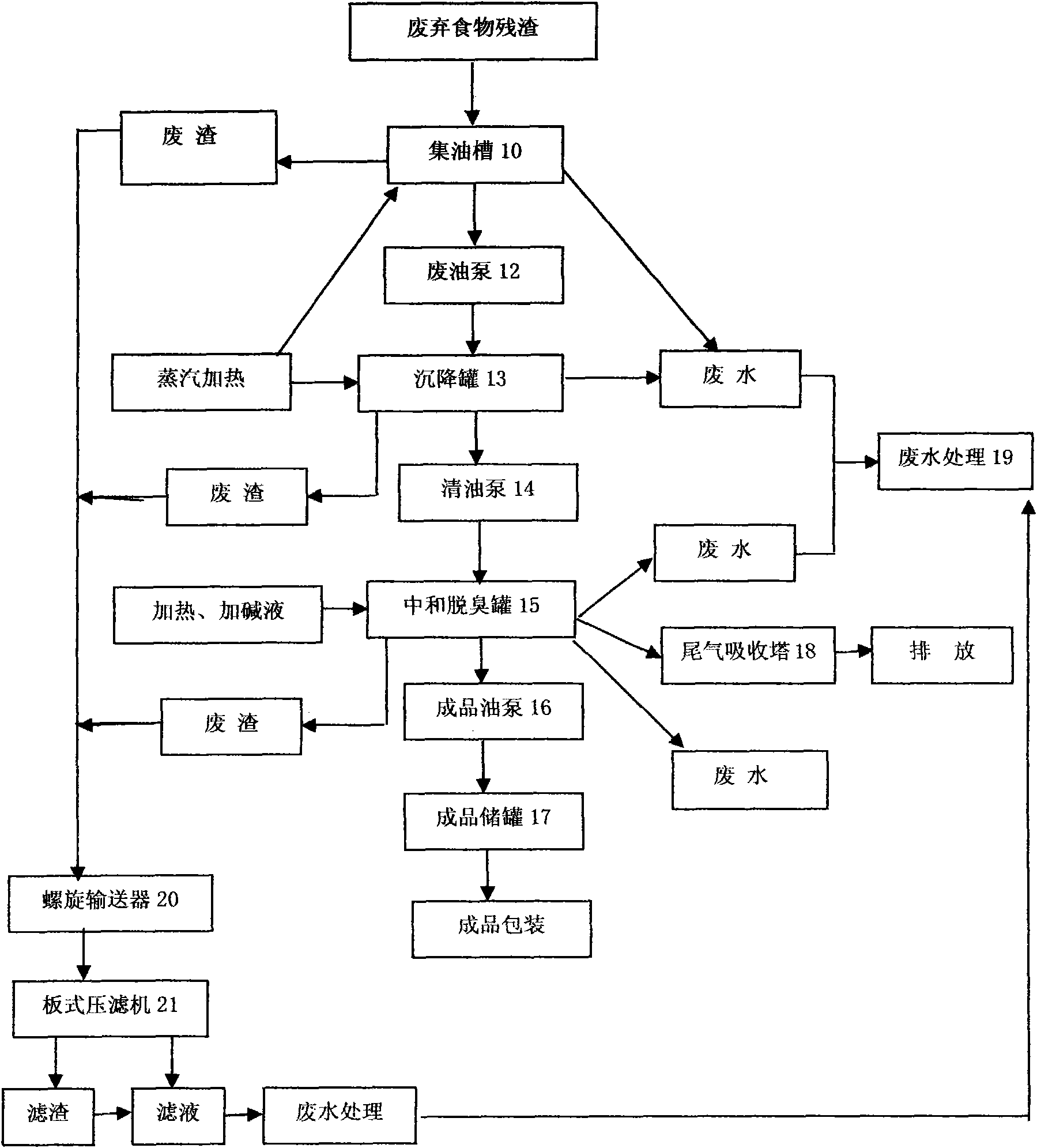

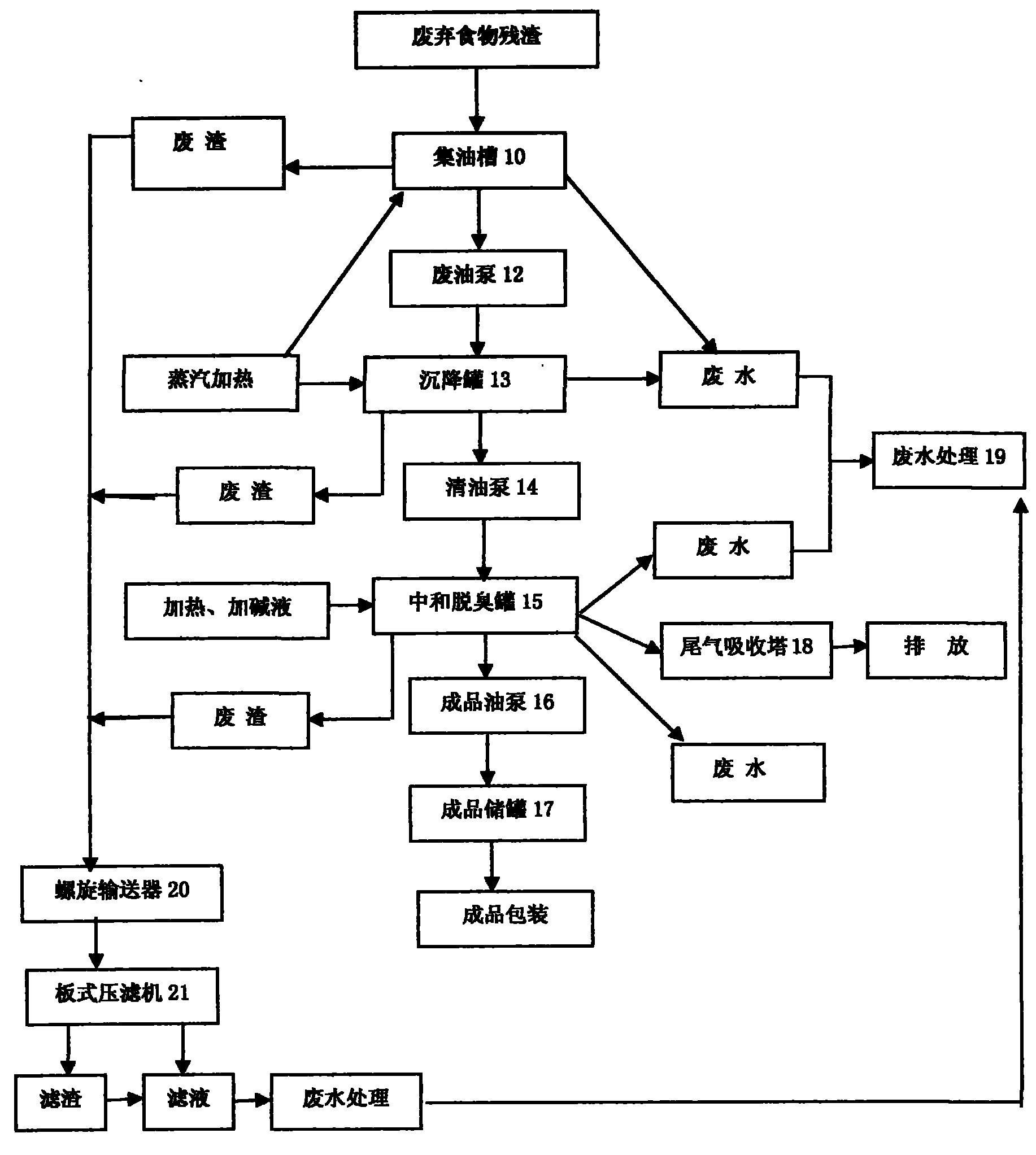

[0026] figure 1 Show the overall composition of the facility of the embodiment of the present invention

[0027] It is mainly composed of filter, oil-water separator, oil collecting tank 10, sedimentation tank 13, neutralization and deodorization tank 15, finished product tank 17, tail gas absorption system, waste water treatment system 19, and waste residue treatment system. Each part is connected in sequence, a waste oil pump 12 is arranged between the oil collecting tank 10 and the settling tank, and a clean oil pump 14 is arranged between the settling tank 13 and the neutralization and deodorization tank 15 .

[0028] The oil collecting tank 10 is provided with a metal filter screen and a heating device. The mesh size of the metal filter screen is 1cm) × 1cm; the heating device is coiled steam heating.

[0029] The settling tank 13 is a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com