Production method for fully using oil-containing micro-algae

A production method and technology for microalgae, which are applied in the field of microalgae utilization engineering, can solve problems such as low utilization efficiency of microalgae, and achieve the effects of short cycle, low production cost and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

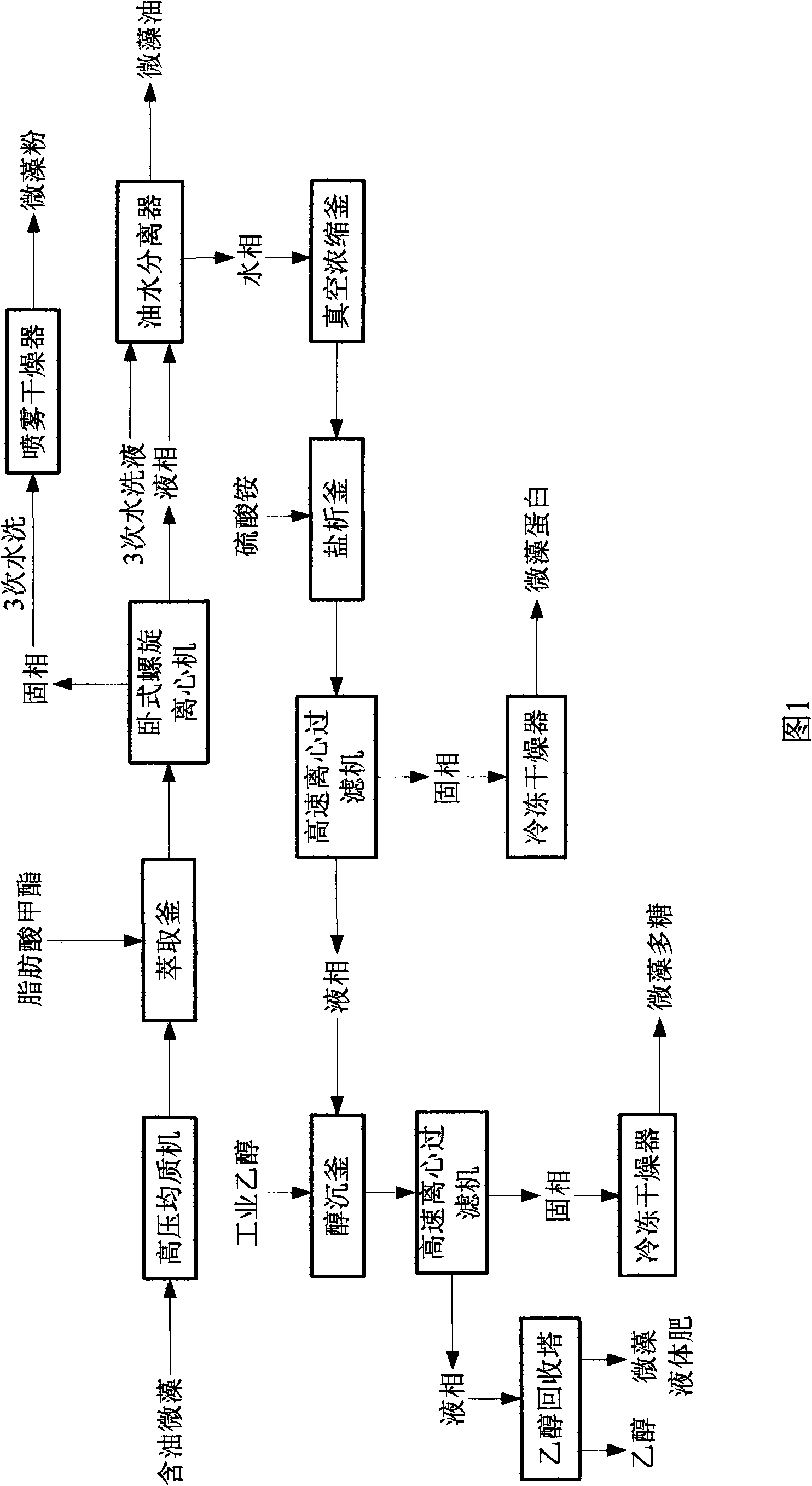

[0018] The present invention will be further described below in conjunction with the accompanying drawings and the embodiments given in the accompanying drawings. The production technique of the present invention is easy to implement for those skilled in the art.

[0019] Referring to Fig. 1, get 1000Kg harvested green Pavlova, with a moisture content of 90%, and after homogenizing once with a homogenizing pressure of 20MPa with a high-pressure homogenizer at room temperature, a wall breaking rate of more than 95% is achieved. The material after breaking the wall enters 2m 3 The extraction kettle, and add 300Kg fatty acid methyl ester, extract microalgae oil under stirring state, extraction temperature is 70 ℃, and extraction time is 4 hours.

[0020] The extracted material was separated from liquid to solid by a horizontal spiral centrifuge, and the separated solid phase was washed with water three times, then added to a spray dryer for drying to obtain 16Kg of microalgae po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com