Preparation method of modified bagasse cellulose based heavy metal adsorbent

A cellulose-based, heavy metal technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of uneconomical extraction process, complicated steps, application restrictions, etc., and achieve environmental protection Friendly adsorption effect, simple preparation method, and the effect of solving secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

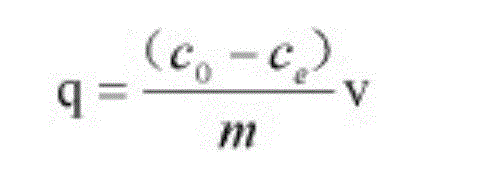

Method used

Image

Examples

Embodiment 1

[0031] Weigh 2g of dried cellulose into 20ml of dimethyl sulfoxide, heat and stir in a water bath at 60°C for gelatinization for 20 minutes, add 50ml of deionized water to the gelatinized cellulose, Then add 0.5g of initiator ammonium persulfate, feed nitrogen, and initiate at a temperature of 60°C for 30 minutes; add 5g of acrylic acid to the above mixed system, mix well and react at 50°C for 60 minutes to obtain a graft copolymerization product, Finally, 2 g of diethylenetriamine was added dropwise, reacted at the same temperature for 40 min, and the obtained product was repeatedly washed with distilled water, and then dried at 60° C. for 5 h to obtain the crude product of the fiber-based heavy metal adsorbent.

Embodiment 2

[0033] Weigh 2g of dried cellulose into 20ml of dimethyl sulfoxide, heat and stir in a water bath at 60°C for gelatinization for 20 minutes, add 50ml of deionized water to the gelatinized cellulose, Then add 0.5g of initiator ammonium persulfate, feed nitrogen, and initiate at a temperature of 60°C for 30 minutes; add 2g of acrylic acid to the above mixed system, mix well and react at 50°C for 60 minutes to obtain a graft copolymerization product. Finally, 2 g of diethylenetriamine was added dropwise, reacted at the same temperature for 40 min, and the obtained product was repeatedly washed with distilled water, and then dried at 60° C. for 5 h to obtain the crude product of the fiber-based heavy metal adsorbent.

Embodiment 3

[0035] Weigh 2g of dried cellulose into 20ml of dimethyl sulfoxide, heat and stir in a water bath at 60°C for gelatinization for 20 minutes, add 50ml of deionized water to the gelatinized cellulose, Then add 0.5g of initiator cerium ammonium nitrate, feed nitrogen, and initiate at a temperature of 60°C for 30 minutes; add 5g of acrylic acid to the above mixed system, mix well and react at 50°C for 60 minutes to obtain a graft copolymerization product, Finally, 1 g of diethylenetriamine was added dropwise and reacted at the same temperature for 40 minutes. The obtained product was repeatedly washed with distilled water and dried at 60° C. for 5 hours to obtain the crude product of the fiber-based heavy metal adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com