Preparation of polymer flooding produced fluid demulsifier

A demulsifier and polymer technology, which is applied in the field of chemical treatment agent preparation for oilfield produced fluid, can solve the problems of high technical difficulty, inability to meet production and technical requirements, and difficulty in separating oil and water from produced fluid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

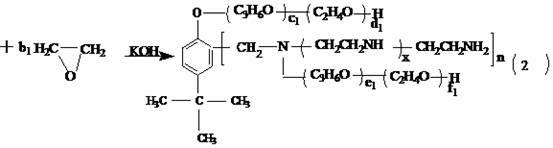

[0029] 1) Add 150kg of p-tert-butylphenol and 280kg of polyethylene polyamine into the reaction equipment, raise the temperature to 90-95°C, after the materials are fully dissolved, cool down to 20°C, add 100kg of formaldehyde dropwise, and control the temperature and speed of dropping; After the reaction is completed, add 100kg of xylene, heat up to 130-160°C, reflux and separate water until there is no more moisture, and then obtain a phenolic resin.

[0030] 2) Put 200kg of phenolic resin into the reactor while it is hot, vacuum for 15 minutes, the pressure in the reactor reaches the lowest, add 8kg of potassium hydroxide (50% aqueous solution) as a catalyst, stir evenly, heat up to 110-140℃ steadily, vacuum Dehydration, until the moisture is removed, fill with nitrogen to normal pressure, add 4000 kg of propylene oxide dropwise, keep the reaction temperature between 120-160°C, keep the temperature for 1-1.5 hours after the dropwise addition, and then vacuum for 15 minutes; ...

Embodiment 2

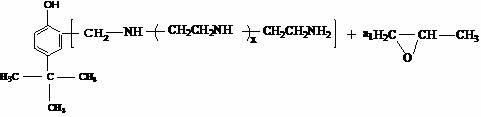

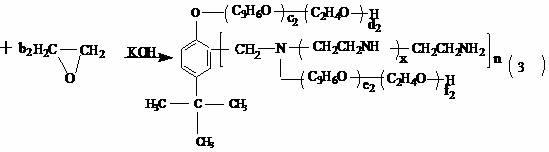

[0036] 1) Add 150kg of p-tert-butylphenol and 560kg of polyethylene polyamine into the reaction equipment, raise the temperature to 90-95°C, after the materials are fully dissolved, cool down to 20°C, add 200kg of formaldehyde dropwise, and control the temperature and speed of dropping; After the reaction is completed, add 150kg of xylene, heat up to 130-160°C, reflux and separate water until there is no more moisture, and then obtain a phenolic resin.

[0037] 2) Put 200kg of phenolic resin into the reactor while it is hot, vacuum for 15 minutes, the pressure in the reactor reaches the lowest, add 10kg of potassium hydroxide (50% aqueous solution) as a catalyst, stir evenly, and raise the temperature steadily to 110-140°C, vacuum Dehydration, until the moisture is removed, fill with nitrogen to normal pressure, add 5500kg of propylene oxide dropwise, keep the reaction temperature between 120-160°C, keep the reaction for 1-1.5 hours after the addition is completed, and vacuum f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com