Viscosity reducing polycarboxylate-type water reducing agent for high-performance concrete

A technology for high-performance concrete and viscous polycarboxylic acid, which is applied in the preparation of this water-reducing agent, and in the field of viscosity-reducing polycarboxylic acid-based high-performance water-reducing agent, can solve the problems of reduction and no description of the preparation process. , to achieve the effect of simple process, obvious viscosity reduction effect and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

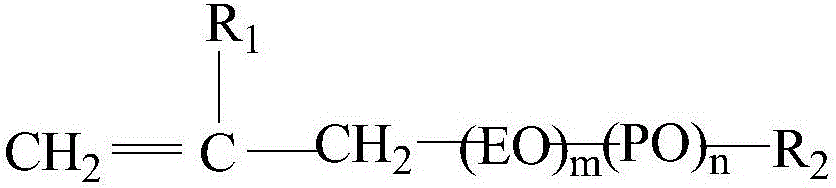

Method used

Image

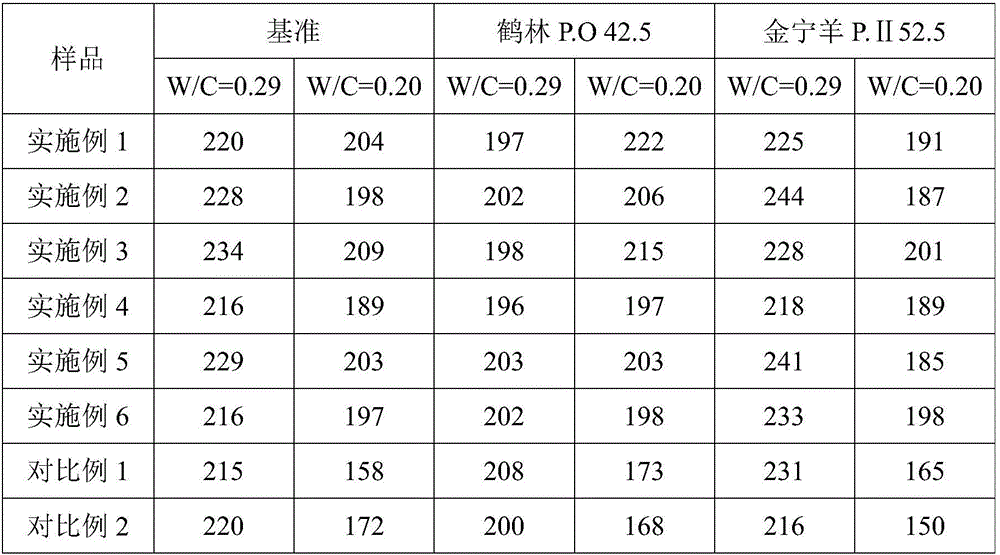

Examples

Embodiment 1

[0025] (1) Preparation of comonomer A: Add 97.5 parts of diethylenetriamine and 115 parts of methanol to a four-necked flask equipped with a thermometer, a stirrer, a constant pressure funnel, a reflux condenser and a water separator, Stir evenly at 30°C; add 287.5 parts of propyl acrylate dropwise in 0.5h~1h; heat up to 50°C~55°C and keep warm for 4h~6h; continue to heat up to 75°C for vacuum distillation to obtain a light yellow comonomer solution .

[0026] (2) Preparation of viscosity-reducing polycarboxylate water reducer: add 27.5 parts of prepared comonomer A, 383.3 parts of methallyl polyoxyethylene polyoxypropylene ether comonomer ( Molecular weight 2400), 5.7 parts of p-methylstyrene and 260 parts of water, heated to 60 ℃ ~ 65 ℃ while stirring, adding 2.40 parts of sodium persulfate; then 62 parts of methacrylic acid, 1.92 parts of mercaptoethanol, 1.44 parts of butyl Make a mixed solution of mercaptan and 203 parts of water, and drop it at a constant rate within 3h...

Embodiment 2

[0028] (1) Preparation of comonomer A: Add 271.5 parts of diethylenetriamine and 115 parts of methanol to a four-necked flask equipped with a thermometer, a stirrer, a constant pressure funnel, a reflux condenser and a water separator, Stir evenly at 30°C; add 113.5 parts of methyl acrylate dropwise in 0.5h-1h; heat up to 50°C-55°C and keep warm for 4h-6h; continue to heat up to 75°C for vacuum distillation to obtain a light yellow comonomer solution .

[0029] (2) Preparation of viscosity-reducing polycarboxylate water reducer: add 18.8 parts of prepared comonomer A, 388.2 parts of isopentenyl polyoxyethylene polyoxypropylene ether comonomer (molecular weight 2400), 11.3 parts of α-methylstyrene and 260 parts of water, heated to 60°C~65°C while stirring, and added 2.36 parts of azobisisobutylimidium hydrochloride; then 23.3 parts of acrylic acid, 31.7 parts of Acid anhydride, 4.76 parts of isopropanol, 1.88 parts of octyl mercaptan, and 198.5 parts of water are mixed into a ...

Embodiment 3

[0031] (1) Preparation of comonomer A: Add 221.3 parts of triethylenetetramine and 115 parts of methanol to a four-necked flask equipped with a thermometer, agitator, constant pressure funnel, reflux condenser and water separator, Stir evenly at 30°C; add 163.7 parts of methyl acrylate dropwise in 0.5h-1h; heat up to 50°C-55°C and keep warm for 4h-6h; continue to heat up to 75°C for vacuum distillation to obtain a light yellow comonomer solution .

[0032] (2) Preparation of viscosity-reducing polycarboxylate water reducer: add 19.4 parts of prepared comonomer A, 378.7 parts of methallyl polyoxyethylene polyoxypropylene ether comonomer ( Molecular weight 3000), 6.6 parts of styrene and 260 parts of water, heated to 60 ℃ ~ 65 ℃ while stirring, added 2.88 parts of ammonium persulfate; then 73.2 parts of fumaric acid, 2.40 parts of thioglycolic acid, 1.92 parts of 3-mercaptopropane A mixed solution of octyl acid and 205.4 parts of water, and drop it at a constant rate within 3h~...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com