Preparation method of modified polymer film material for effectively removing trace heavy metal ions in water body

A technology of heavy metal ions and polymer membranes, which is applied to water pollutants, chemical instruments and methods, and membrane technology. Use effects and other issues to achieve the effects of easy industrial continuous processing, flexible design, and long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

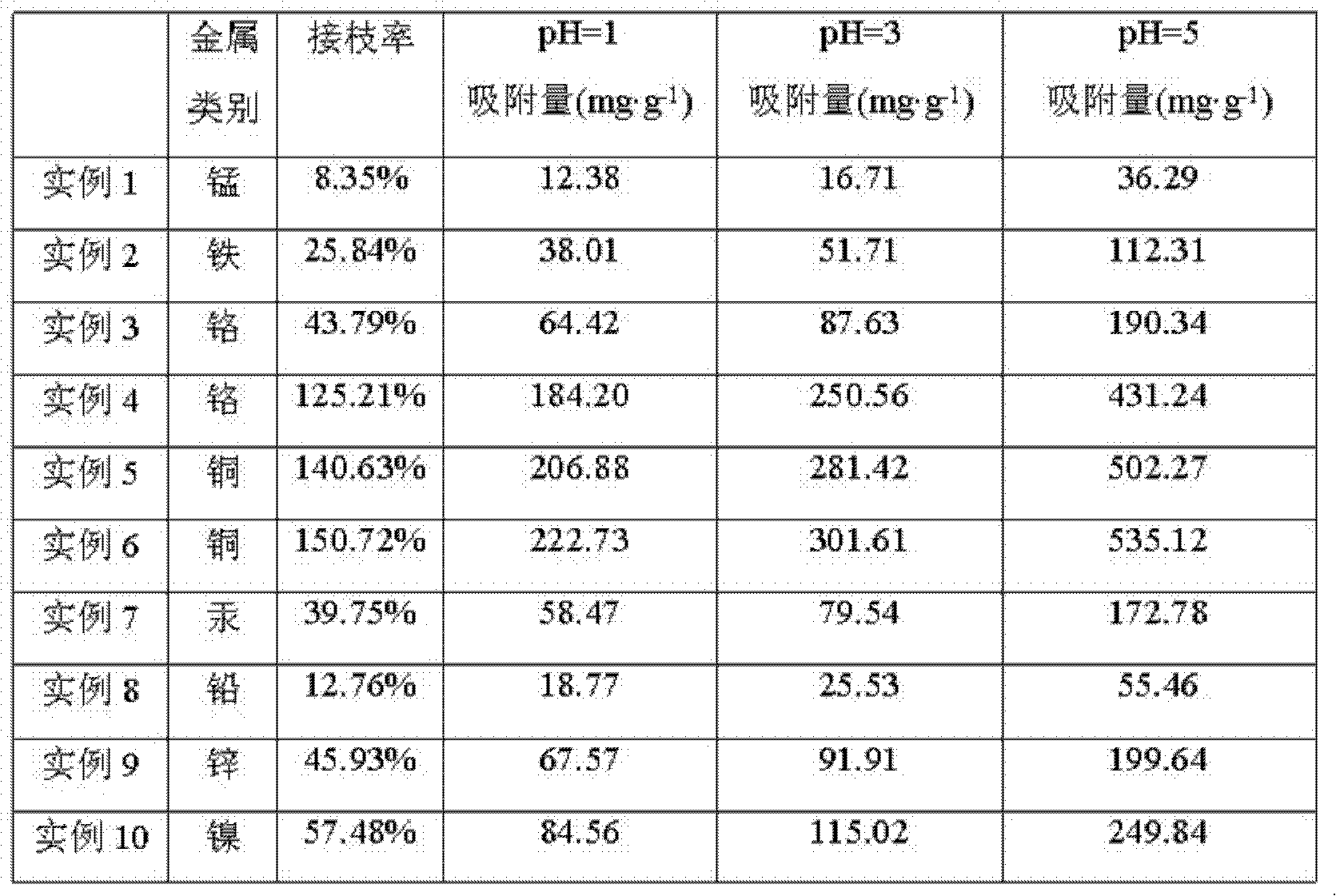

Examples

Embodiment 1

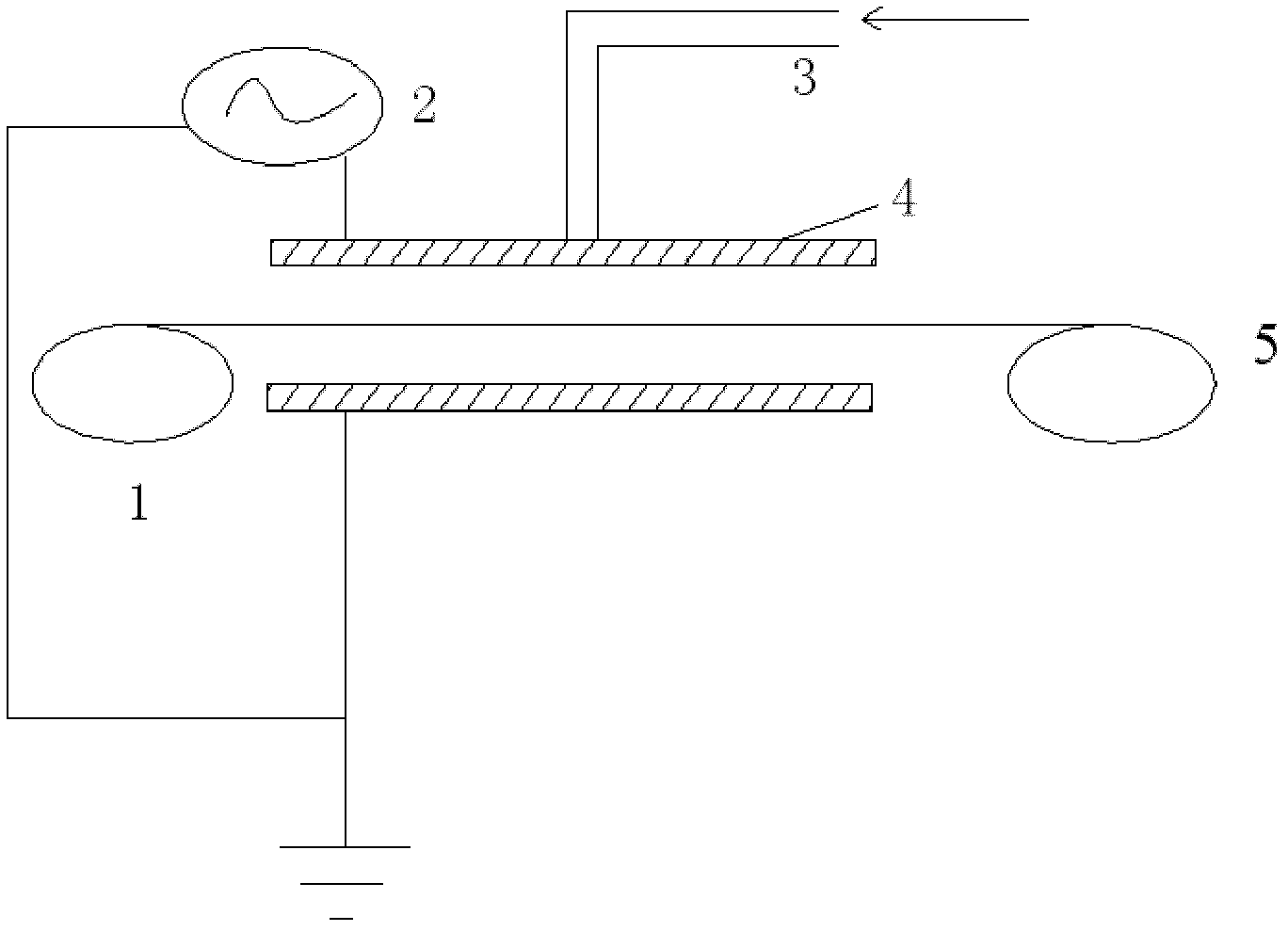

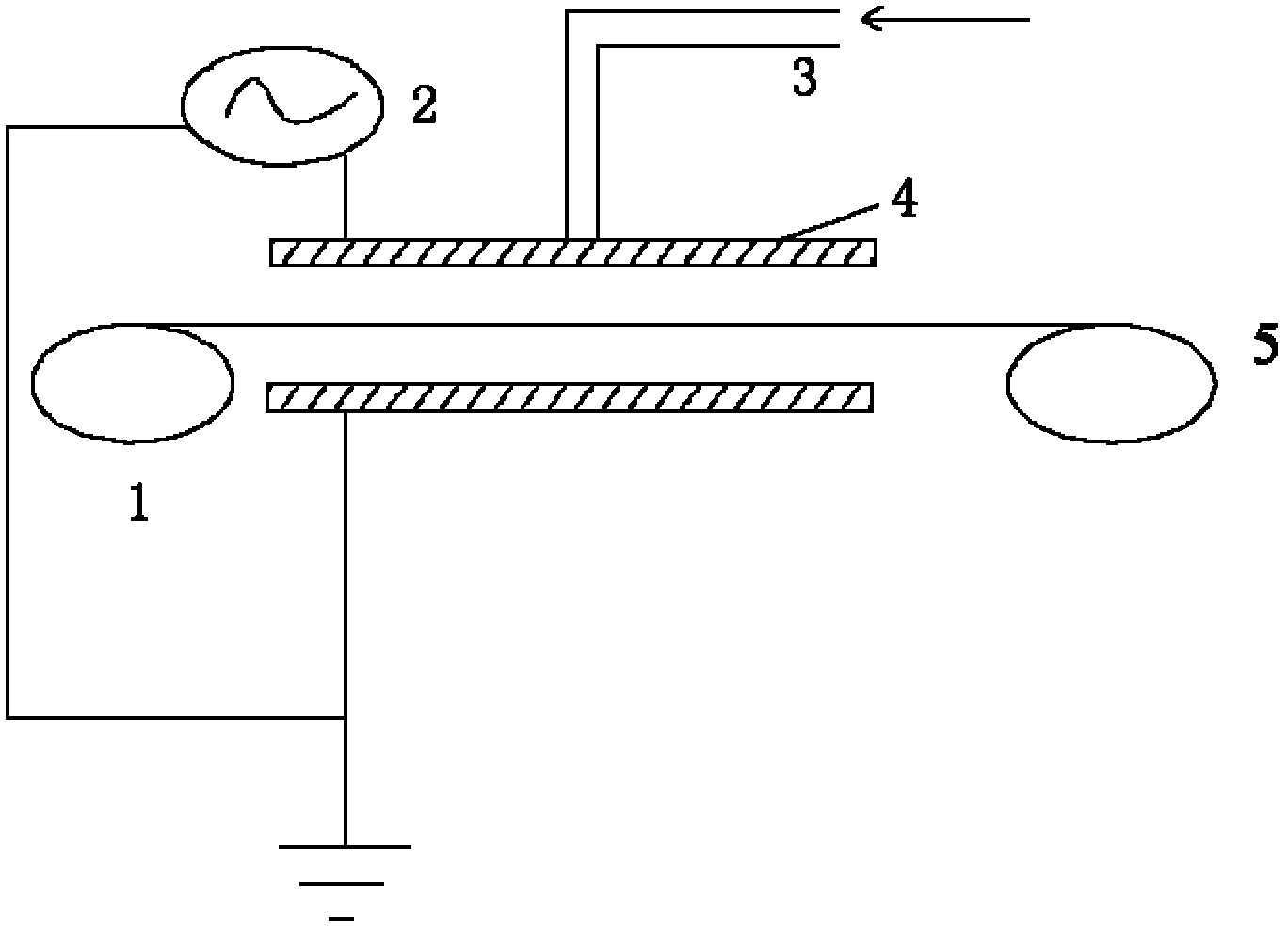

[0038] to combine figure 1 , the continuous treatment process of the polymer film with atmospheric pressure dielectric barrier discharge plasma is as follows:

[0039] The polypropylene film 1 to be treated is passed between two discharge electrodes 4 of the plasma device, and then wound on an automatic winder 5 . The automatic winder 5 can wind the processed polypropylene film online, and adjust the line speed of the polypropylene film by adjusting the rotation speed of the winding shaft.

[0040] Adjust the distance between the two discharge electrodes 4 to be 1.5 centimeters, first pass into the mixed gas from the air guide tube 3, the mixed gas is argon and oxygen with a volume ratio of 99:1, and adjust the intake speed to be 4 liters / minute; then open Power supply, close the switch of the plasma generator 2, adjust the plasma discharge power to 120 watts, and the discharge frequency to 10 kHz to generate uniform plasma. When the polypropylene film passes between the pla...

Embodiment 2

[0043] The polypropylene film is placed between the two discharge electrodes of the dielectric barrier discharge, and argon gas is introduced to carry out the normal pressure dielectric barrier discharge plasma treatment. The normal pressure dielectric barrier discharge plasma treatment condition is: the distance between the discharge electrodes is 2 centimeters; a mixture of argon and oxygen with a volume ratio of 99.5:0.5 is introduced, and the intake velocity is 10 liters / minute; the discharge power of the plasma is 100 watts, and the discharge frequency is 10 kilohertz, and the wiring of the polypropylene film The speed is 15 m / min, and the plasma treatment time is 40 seconds; diphenyl (2,4,6-trimethylbenzoyl) phosphine oxide is dissolved in n-heptane to prepare an initiator solution with a concentration of 20mmol / L , dissolve rosin resin acid in water to prepare a monomer solution with a concentration of 40 g / L, use potassium dihydrogen phosphate and sodium hydroxide to pr...

Embodiment 3

[0045] The polystyrene film is placed between the two discharge electrodes of the dielectric barrier discharge, and helium gas is introduced to carry out the dielectric barrier discharge plasma treatment at normal pressure. The plasma treatment conditions of the dielectric barrier discharge at normal pressure are: the distance between the discharge electrodes is 3 cm; a mixed gas of helium and oxygen with a volume ratio of 97:3 is introduced, and the intake velocity is 6 liters / minute; the discharge power of the plasma is 50 watts, and the discharge frequency is 10 kHz, and the polystyrene film The line speed is 3.3 m / min, and the plasma treatment time is 180 seconds; the initiator solution that the benzoin dimethyl ether is dissolved in n-heptane configuration concentration is 30mmol / L, and the methacrylic acid is dissolved in water configuration concentration is 60g / L L monomer solution, use potassium dihydrogen phosphate and sodium hydroxide to prepare a buffer solution with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com