Preparation method and application of heavy metal ion absorbent

A technology of heavy metal ions and adsorbents, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc. Fewer modification steps, faster speed, and improved adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

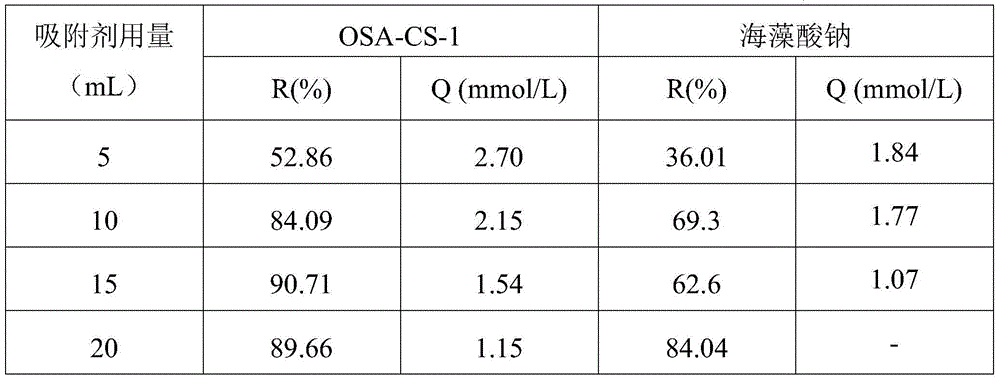

Examples

Embodiment 1

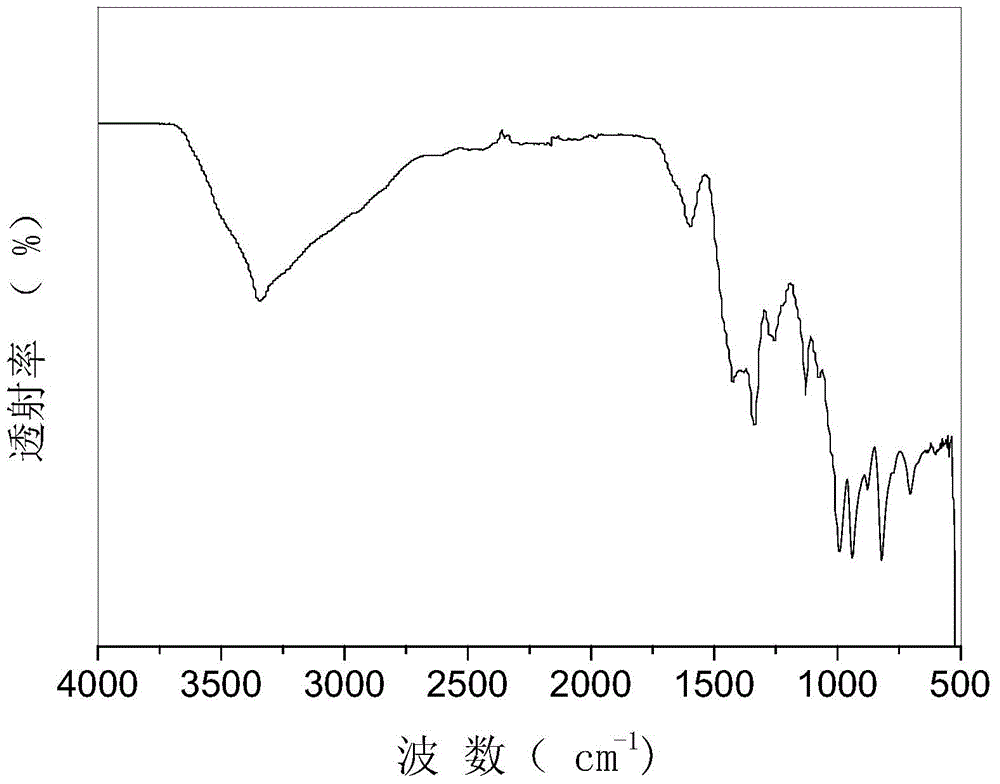

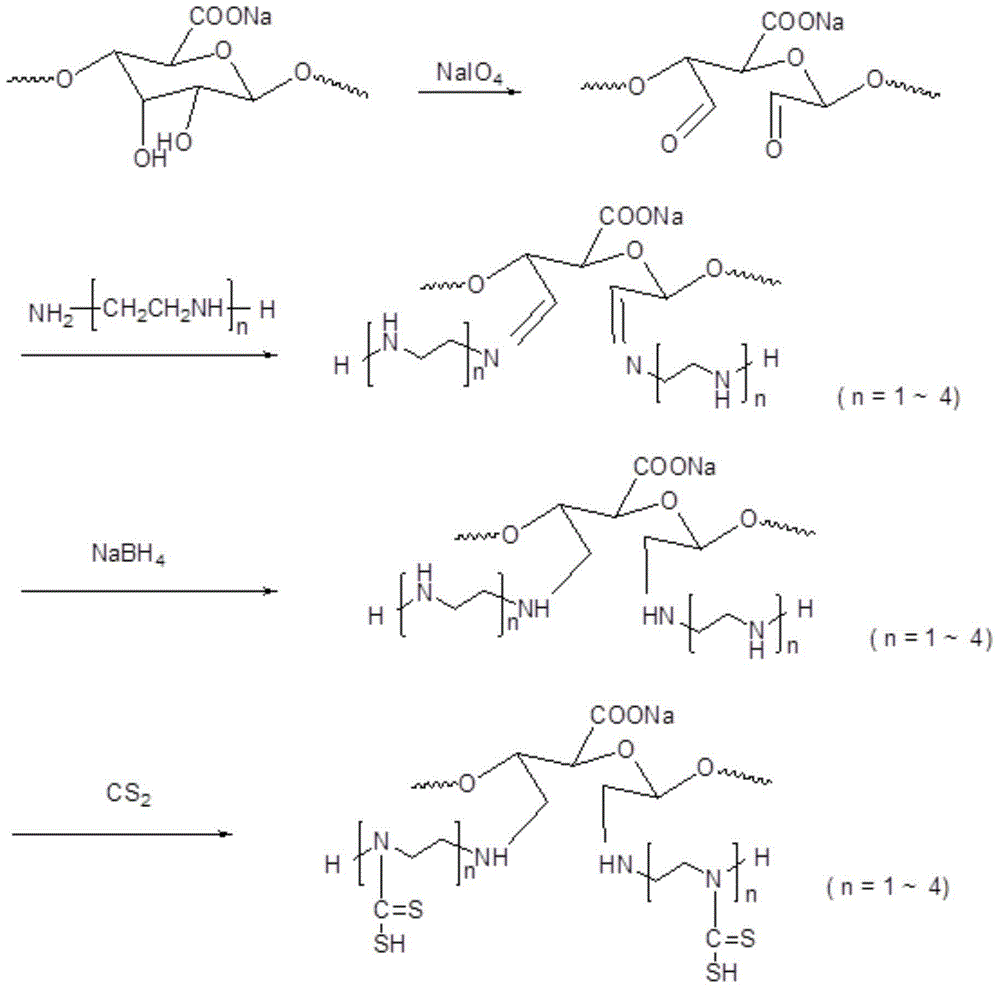

[0025] Adsorbent OSA-NH 4 - Preparation of CS-1

[0026] Add 100mL absolute ethanol to 20g sodium alginate (SA) powder, magnetically stir to disperse evenly, add 100mL concentration of 0.8mol / L sodium periodate (NaIO 4 ) solution, reacted at room temperature in the dark for 12 hours, added 4.5 mL of ethylene glycol, and continued to react for 2 hours. The solution was suction filtered, the product was fully stirred and washed with 50% ethanol, and the suction filtration was repeated twice. The obtained product was dried in an oven at 55° C. for 24 hours to obtain aldehyde sodium alginate (OSA).

[0027] Take 5g of OSA in 80mL of water to make a homogeneous solution, add 80mL of tetraethylenepentamine aqueous solution with a concentration of 1mol / L, and react with magnetic stirring in a water bath at 40°C for 24h, then cool to room temperature. Add 3.02g NaBH in batches 4 , and continue to react for 24h to obtain amino sodium alginate.

[0028] In the above reacted solutio...

Embodiment 2

[0033] Adsorbent OSA-NH 4 - Preparation of CS-2

[0034] Add 100mL of absolute ethanol to 18g of sodium alginate (SA) powder, magnetically stir to disperse evenly, add 263mL of sodium periodate (NaIO 4 ) solution, reacted at room temperature in the dark for 12 hours, added 4.1 mL of ethylene glycol, and continued to react for 2 hours. The solution was suction filtered, the product was fully stirred and washed with 50% ethanol, and the suction filtration was repeated twice. The obtained product was dried in an oven at 55° C. for 24 hours to obtain aldehyde sodium alginate (OSA).

[0035] Take 5g OSA in 80mL water to make a homogeneous solution, add 34mL triethylenetetramine aqueous solution with a concentration of 1mol / L, stir and react in a water bath at 40°C for 24h, then cool to room temperature. Add 3.02g NaBH in batches 4 , and continue to react for 24h to obtain amino sodium alginate.

[0036] In the above reacted solution, add CS 2 mixed solution with NaOH, the mix...

Embodiment 3

[0038] Adsorbent OSA-NH 4 - Preparation of CS-3

[0039]Add 100mL of absolute ethanol to 25g of sodium alginate (SA) powder, magnetically stir to disperse evenly, add 183mL of sodium periodate (NaIO 4 ) solution, reacted at room temperature in the dark for 12 hours, added 5.6 mL of ethylene glycol, and continued to react for 2 hours. The solution was suction filtered, the product was fully stirred and washed with 50% ethanol, and the suction filtration was repeated twice. The obtained product was dried in an oven at 55° C. for 24 hours to obtain aldehyde sodium alginate (OSA).

[0040] Take 5g of OSA in 80mL of water to make a homogeneous solution, add 53mL of 1mol / L tetraethylenepentamine aqueous solution, stir the reaction in a water bath at 40°C for 24h, then cool to room temperature. Add 3.02g NaBH in batches 4 , and continue to react for 24h to obtain amino sodium alginate.

[0041] In the above reacted solution, add CS 2 mixed solution with NaOH, the mixed solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com