Crude oil desalting agent and preparation method thereof

A technology of desalting agent and crude oil, which is applied in the formulation and preparation of desalting agent, can solve the problems of large amount of demulsifier, excessive salt content of crude oil, poor effect, etc., and achieve good demulsification and desalination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

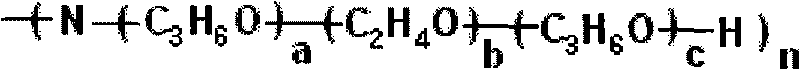

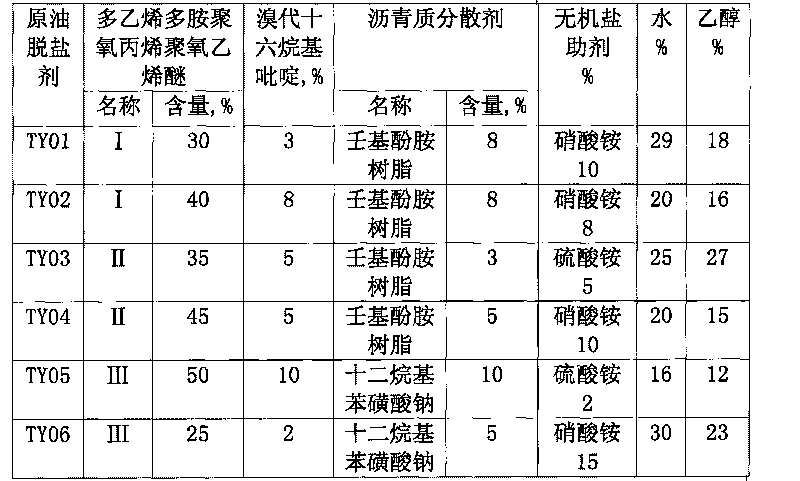

Embodiment 1

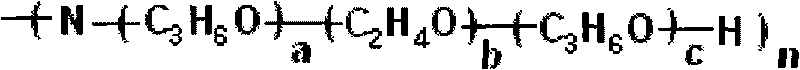

[0033] Add 10g of tetraethylenepentamine and 5g of potassium hydroxide into the autoclave, protect it with nitrogen, and slowly press in 400g of propylene oxide with nitrogen at a temperature of 120°C. During the reaction, it needs to be cooled by cooling water, react for 2.5 hours, and then Slowly press in 500g of ethylene oxide with nitrogen, react at 150°C for 3 hours, finally press in 400g of propylene oxide slowly with nitrogen, react at 120°C for 3 hours, and obtain polyethylene polyamine polyoxypropylene polyoxygen after cooling Vinyl Ether I.

Embodiment 2

[0035] Add 10g of triethylenetetramine and 5g of potassium hydroxide into the autoclave, protect it with nitrogen, and slowly press in 300g of propylene oxide with nitrogen at a temperature of 120°C. During the reaction, it needs to be cooled by cooling water, react for 3 hours, and then Slowly press in 400g of ethylene oxide with nitrogen, react at 150°C for 3 hours, finally press in 300g of propylene oxide slowly with nitrogen, react at 120°C for 3 hours, and obtain polyethylene polyamine polyoxypropylene polyoxygen after cooling Vinyl ether II.

Embodiment 3

[0037] Add 10g of diethylenetriamine and 5g of sodium hydroxide into the autoclave, protect it with nitrogen, and slowly press in 300g of propylene oxide with nitrogen at a temperature of 120°C. During the reaction, it needs to be cooled by cooling water, react for 3 hours, and then Slowly press in 500g of ethylene oxide with nitrogen, react at 150°C for 4 hours, finally press in 400g of propylene oxide slowly with nitrogen, react at 120°C for 5 hours, and obtain polyethylene polyamine polyoxypropylene polyoxygen after cooling Vinyl ether III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com