Preparation method of polyelectrolyte-type crude oil-desalting demulsifier

A technology of polyelectrolyte and demulsifier, which is used in chemical dehydration/demulsification, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of weak binding ability and release of metal cations, etc., and achieves good safety in use and a wide range of sources. , good dehydration and desalination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

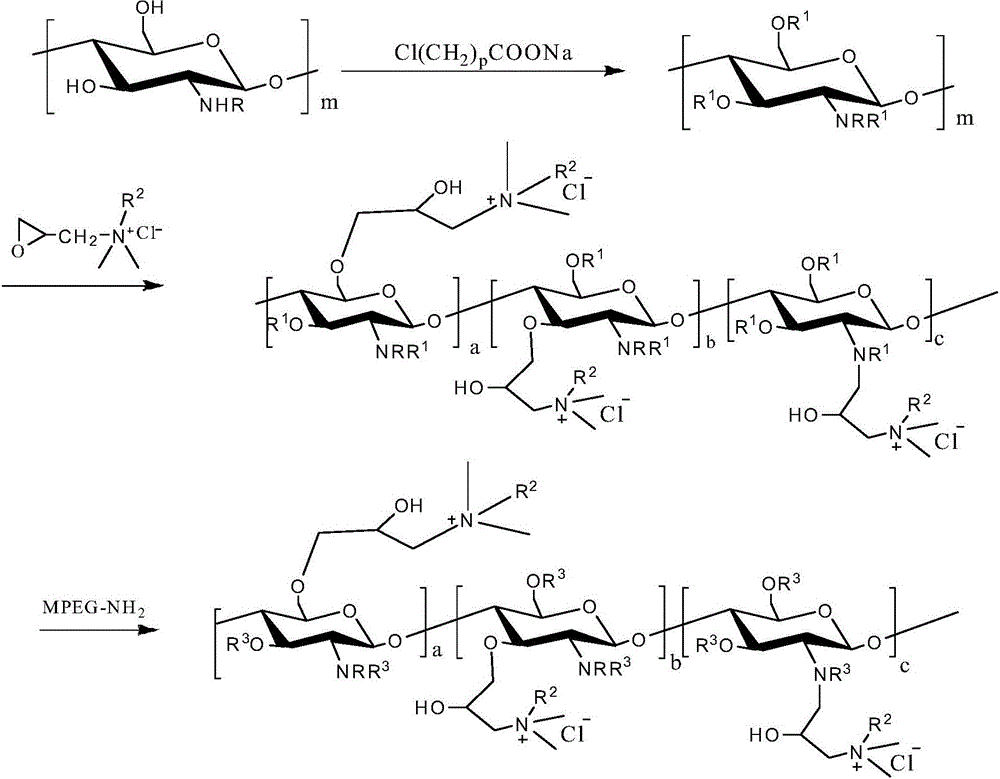

[0046] A kind of preparation of polyelectrolyte type crude oil desalting demulsifier, comprises the steps:

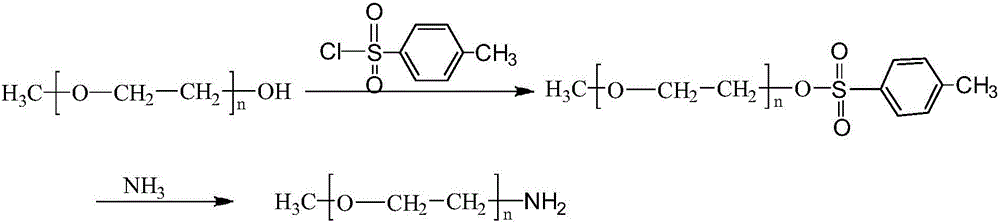

[0047] (1) Amination modification of terminal hydroxyl groups of polyethylene glycol monomethyl ether: Take 1.75 g (5 mmol) of polyethylene glycol monomethyl ether (Mn=350) and dissolve it in 10 mL of dichloromethane, and keep the reaction in an argon atmosphere 0.69mL (5mmol) of triethylamine was added, 2.38g (12.5mmol) of p-toluenesulfonyl chloride dissolved in dichloromethane was slowly added dropwise to the reaction solution, and the reaction was carried out in an ice-water bath (0°C) for 3h. Distill under reduced pressure, add 100 mL of diethyl ether for recrystallization, add the recrystallized product into 3.85 mL (0.1 mol) of ammonia water, and heat to 140° C. for reflux reaction for 6 h. Distilled under reduced pressure and freeze-dried to obtain aminopolyethylene glycol monomethyl ether;

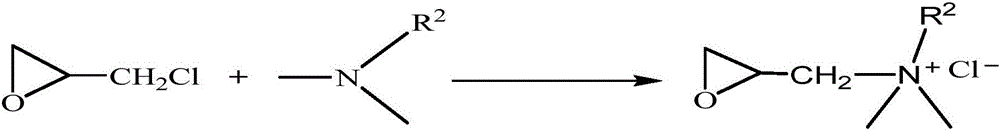

[0048] (2) Preparation of glycidyl dimethyl dodecyl ammonium chloride:...

Embodiment 2

[0053] A kind of preparation of polyelectrolyte type crude oil desalting demulsifier, comprises the steps:

[0054] (1) Amination modification of terminal hydroxyl groups of polyethylene glycol monomethyl ether: take 3.75 g (5 mmol) of polyethylene glycol monomethyl ether (Mn=750) and dissolve it in 10 mL of dichloromethane, and keep the reaction in an argon atmosphere 1.38mL (10mmol) of triethylamine was added, 4.76g (25mmol) of p-toluenesulfonyl chloride dissolved in dichloromethane was slowly added dropwise to the reaction solution, and the reaction was carried out in an ice-water bath (0°C) for 4h. Distill under reduced pressure, add 100 mL of diethyl ether for recrystallization, add the recrystallized product into 3.85 mL (0.1 mol) of ammonia water, heat to 140° C. and reflux for 7 h. Distilled under reduced pressure and freeze-dried to obtain aminopolyethylene glycol monomethyl ether;

[0055] (2) Preparation of glycidyl dimethyltetradecyl ammonium chloride: add 2.41g t...

Embodiment 3

[0060] A kind of preparation of polyelectrolyte type crude oil desalting demulsifier, comprises the steps:

[0061] (1) Amination modification of terminal hydroxyl groups of polyethylene glycol monomethyl ether: take 5 g (5 mmol) of polyethylene glycol monomethyl ether (Mn=1000) and dissolve it in 10 mL of dichloromethane, and keep the reaction in an argon atmosphere , 1.38mL (10mmol) of triethylamine was added, 4.76g (25mmol) of p-toluenesulfonyl chloride dissolved in dichloromethane was slowly added dropwise to the reaction solution, and the reaction was carried out in an ice-water bath (0°C) for 5h. Distill under reduced pressure, add 100 mL of diethyl ether for recrystallization, add the recrystallized product into 3.85 mL (0.1 mol) of ammonia water, heat to 140° C. for reflux reaction for 8 h. Distilled under reduced pressure and freeze-dried to obtain aminopolyethylene glycol monomethyl ether;

[0062](2) Preparation of glycidyl dimethyl cetyl ammonium chloride: add 2.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com