Method for preparing comb-shaped polymer crude oil desalting demulsifier

A comb-shaped polymer and demulsifier technology, which is applied in the field of preparation of comb-shaped polymer crude oil desalting demulsifier, can solve the problems of metal cation removal and weak binding ability, and achieve wide sources, good use safety and good dehydration The effect of the desalination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

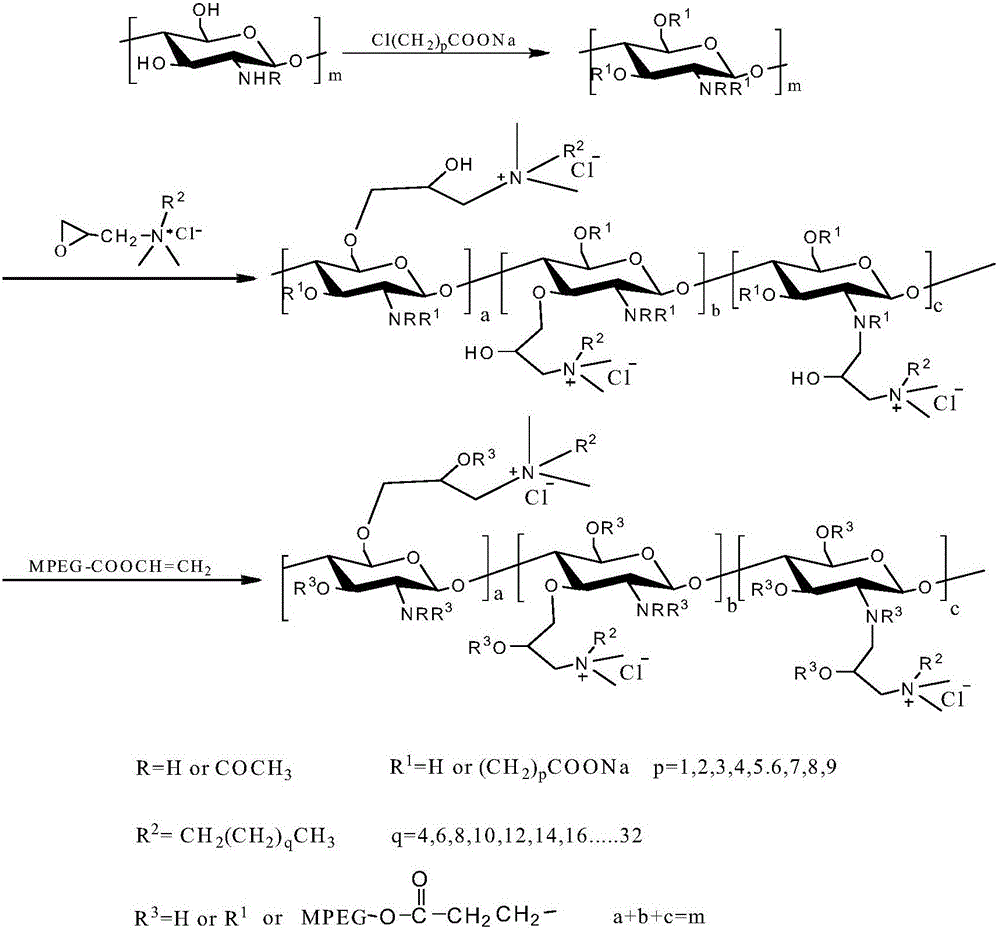

[0044] A kind of preparation of comb polymer crude oil desalting demulsifier comprises the steps:

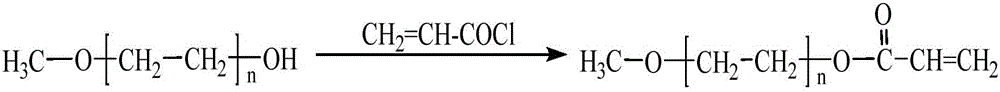

[0045] (1) Acrylation modification of terminal hydroxyl groups of polyethylene glycol monomethyl ether: Take 1.75 g (5 mmol) of polyethylene glycol monomethyl ether (Mn=350) and dissolve it in 30 mL of acetonitrile solution, stir at room temperature, add 1.38 mL (10 mmol) of triethylamine, 0.9 g (10 mmol) of acryloyl chloride dissolved in 10 mL of acetonitrile solution was slowly added dropwise to the reaction solution, and reacted for 20 h. Filtrate, distill under reduced pressure, add 200 mL of ether to recrystallize three times, and dry in vacuum to obtain acrylated polyethylene glycol monomethyl ether.

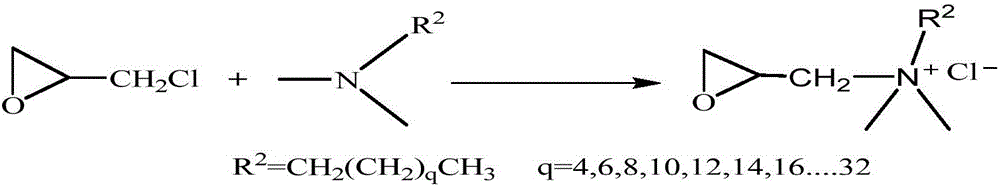

[0046] (2) Preparation of glycidyl dimethyl dodecyl ammonium chloride: add 2.13g of dodecyl dimethyl tertiary amine to the three-necked flask equipped with agitator, dropping funnel and condensation reflux device, constantly stir , take 3.7g of epichlorohydrin through the d...

Embodiment 2

[0051] A kind of preparation of comb polymer crude oil desalting demulsifier comprises the steps:

[0052] (1) Acrylation modification of terminal hydroxyl groups of polyethylene glycol monomethyl ether: Take 3.75 g (5 mmol) of polyethylene glycol monomethyl ether (Mn=750) and dissolve it in 30 mL of acetonitrile solution, stir at room temperature, add 1.66 mL (12 mmol) of triethylamine, 1.35 g (15 mmol) of acryloyl chloride dissolved in 10 mL of acetonitrile solution were slowly added dropwise to the reaction solution, and reacted for 30 h. Filtrate, distill under reduced pressure, add 200 mL of methyl tert-butyl ether for recrystallization three times, and dry in vacuum to obtain acrylated polyethylene glycol monomethyl ether.

[0053] (2) Preparation of glycidyl dimethyltetradecyl ammonium chloride: add 2.41g tetradecyl dimethyl tertiary ammonium to a three-necked flask equipped with a stirrer, dropping funnel and condensing reflux device, constantly stir , take 3.7g of ep...

Embodiment 3

[0058] A kind of preparation of comb polymer crude oil desalting demulsifier comprises the steps:

[0059] (1) Acrylation modification of polyethylene glycol monomethyl ether terminal hydroxyl group: Take polyethylene glycol monomethyl ether (Mn=1000) 5g (5mmol) and dissolve it in 30mL acetonitrile solution, stir at room temperature, add 2mL ( 15mmol) of triethylamine, 1.8g (20mmol) of acryloyl chloride dissolved in 10mL of acetonitrile solution was slowly added dropwise to the reaction liquid, and reacted for 20h. Filtrate, distill under reduced pressure, add 200 mL of isopropyl ether for recrystallization three times, and dry in vacuum to obtain acrylated polyethylene glycol monomethyl ether.

[0060] (2) Preparation of glycidyl dimethyl cetyl ammonium chloride: add 2.69g cetyl dimethyl tertiary amine to a three-necked flask equipped with a stirrer, dropping funnel and condensation reflux device, constantly stir , Take 3.7g of epichlorohydrin and use the dropping funnel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com