Spray and whirl type aerobic fermentation tank

An aerobic fermentation, spray-rotating technology, applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instruments, etc. The bottom erosion is serious and the service life of the tank is short, so as to facilitate the maintenance and operation of the equipment, improve the capacity and mass transfer coefficient and unit output, and reduce the mechanical stirring load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

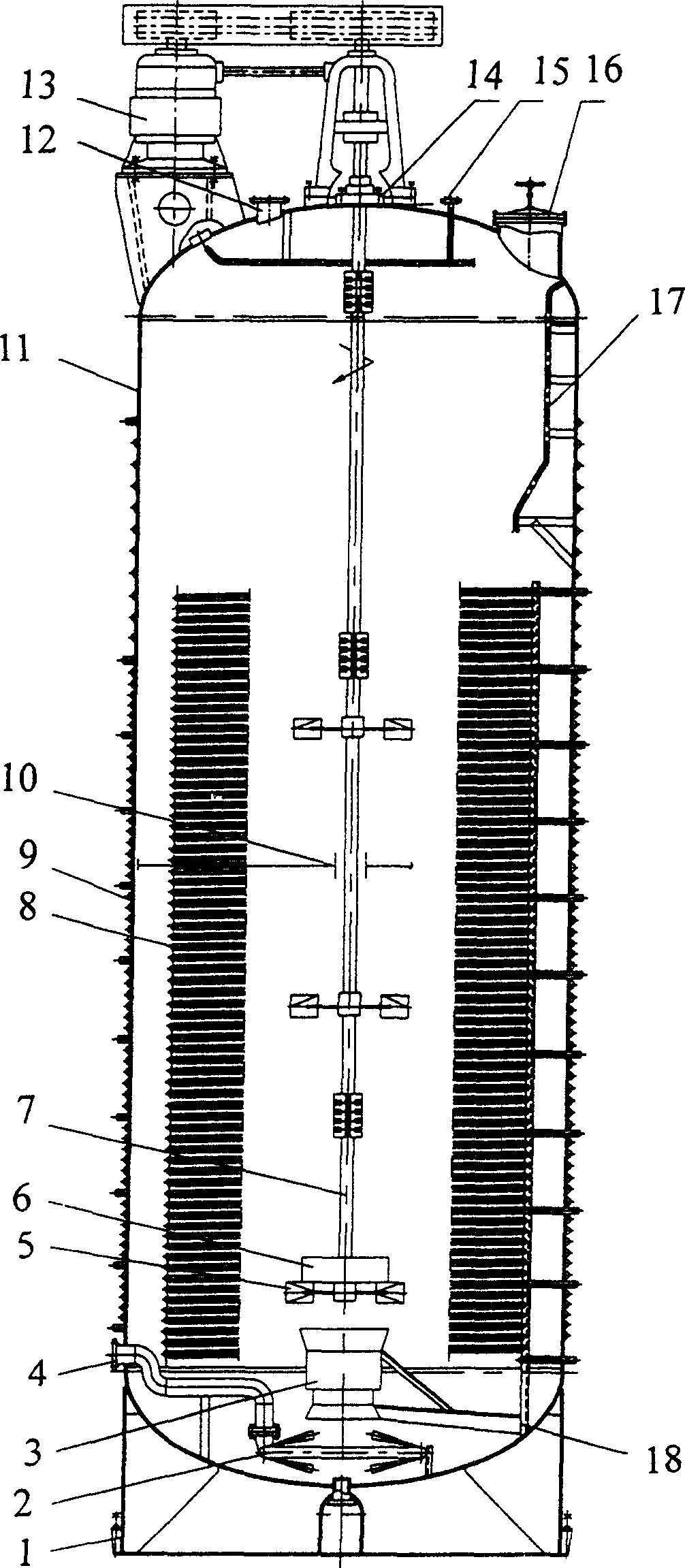

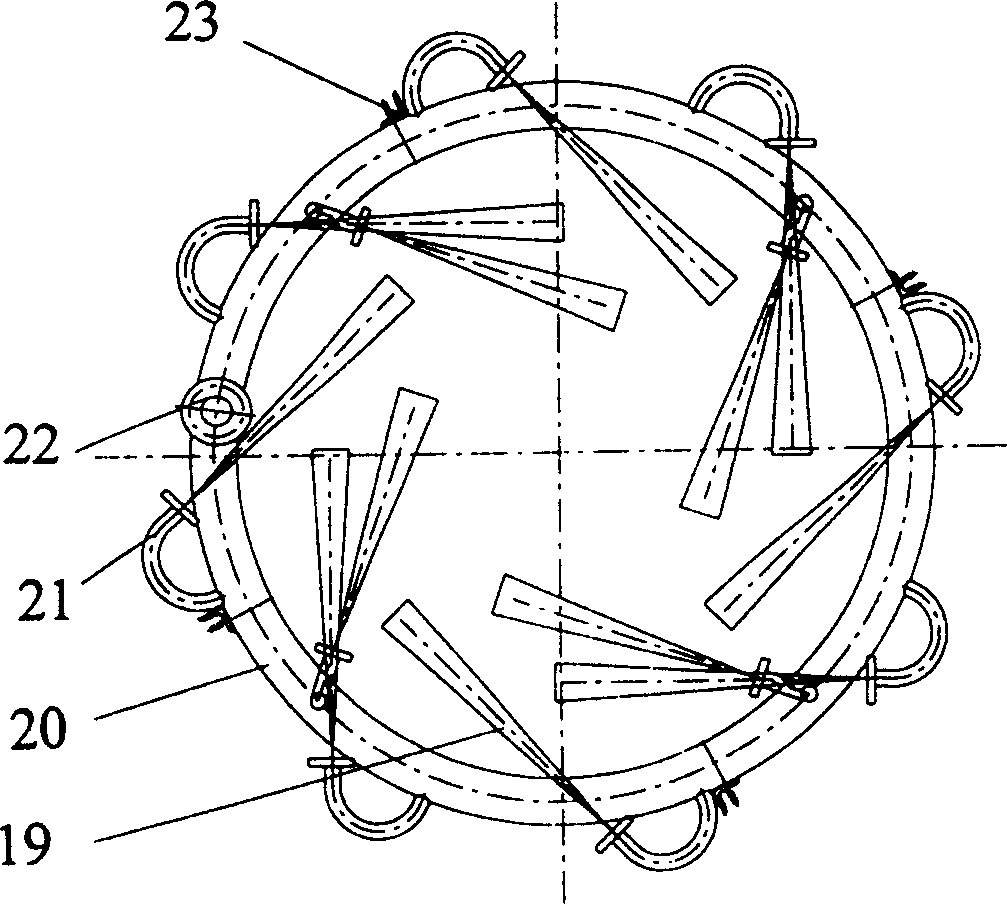

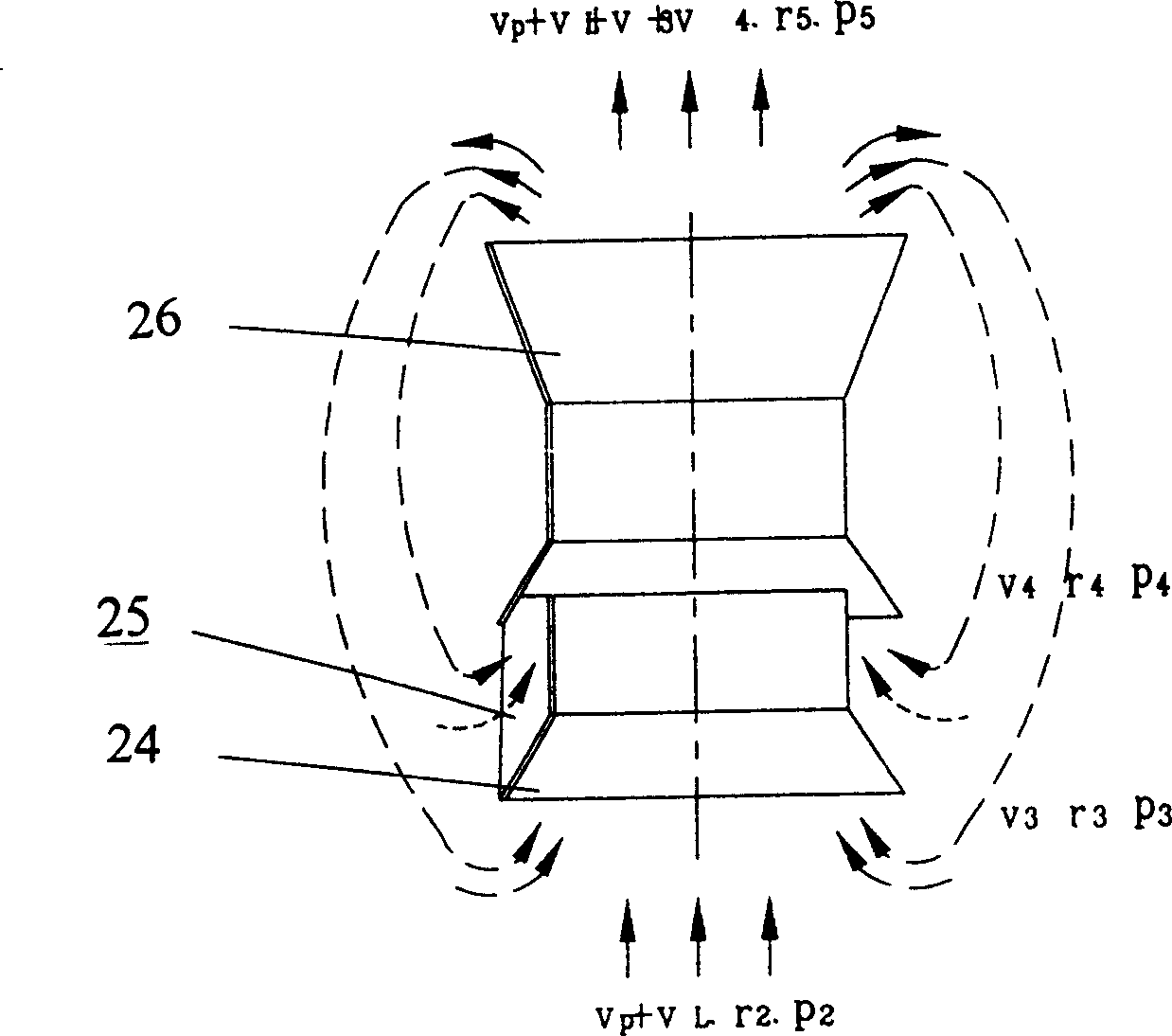

[0010] exist figure 1 Among them, the present invention includes a housing 11, a base 1, a mechanical stirrer 5 and a fixed frame 18, the housing 11 is fixedly connected to the base 1, and the housing 11 is provided with a manhole 16, an air inlet 4 and The air outlet 12, the housing 11 is fixedly connected with the inner coil 8, the housing 11 is provided with a transmission device 13, and the housing 11 is provided with a rotating shaft 7, and the transmission device 13 is matched with the rotating shaft 7 , a mechanical stirrer 5 is installed on the rotating shaft 7, and the rotating shaft 7 and the mechanical stirrer 5 are located in the space surrounded by the inner coil tube 8, and the ejector 3 is installed under the mechanical stirrer 5, and the ejector The bottom of 3 is provided with jet mixing and stirring device 2, which is connected with air inlet 4; A special-shaped pipe 9 is fixedly arranged, and the special-shaped pipe 9 is spirally coiled around the casing 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com