An integrated flotation equipment for quantitative dosing, reverse stirring, central slurry adjustment

A reverse stirring and integrated technology, which is applied in flotation, mixer accessories, mixers with rotating stirring devices, etc., to achieve the effect of simple structure of the stirring mechanism, rich bubbles, and improved mixing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

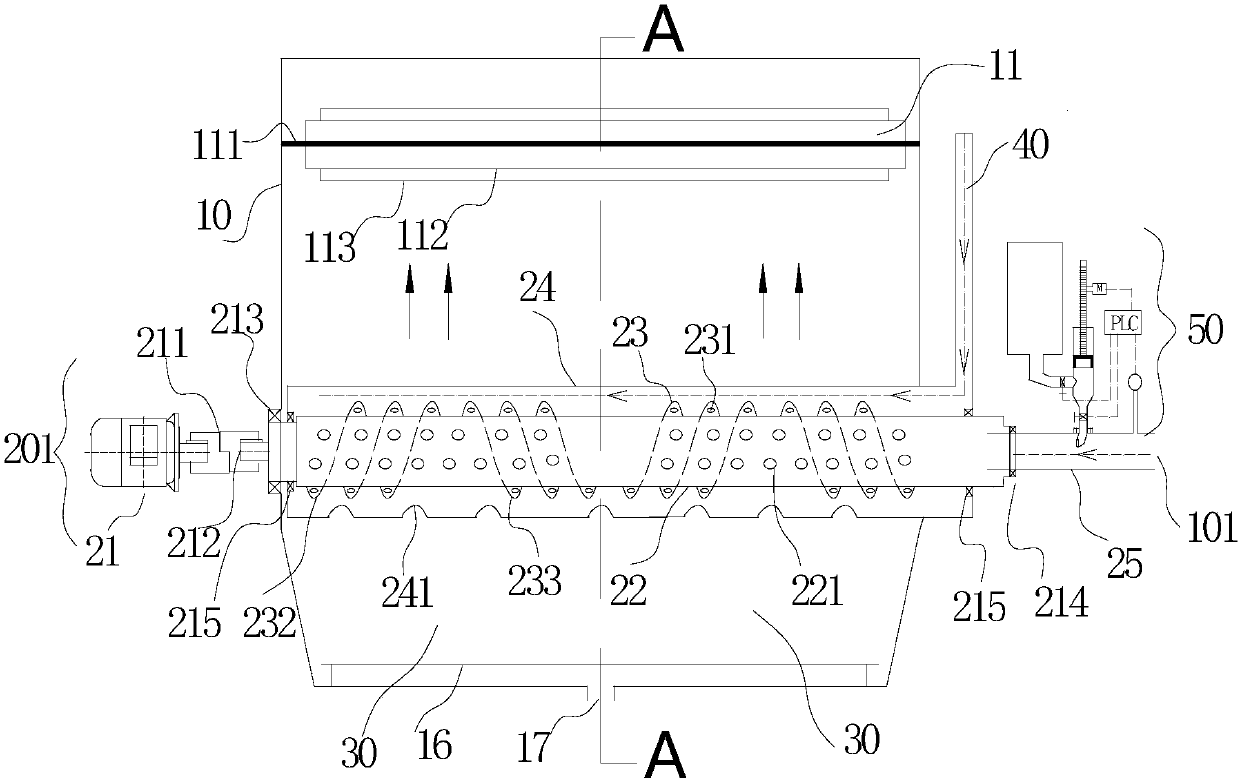

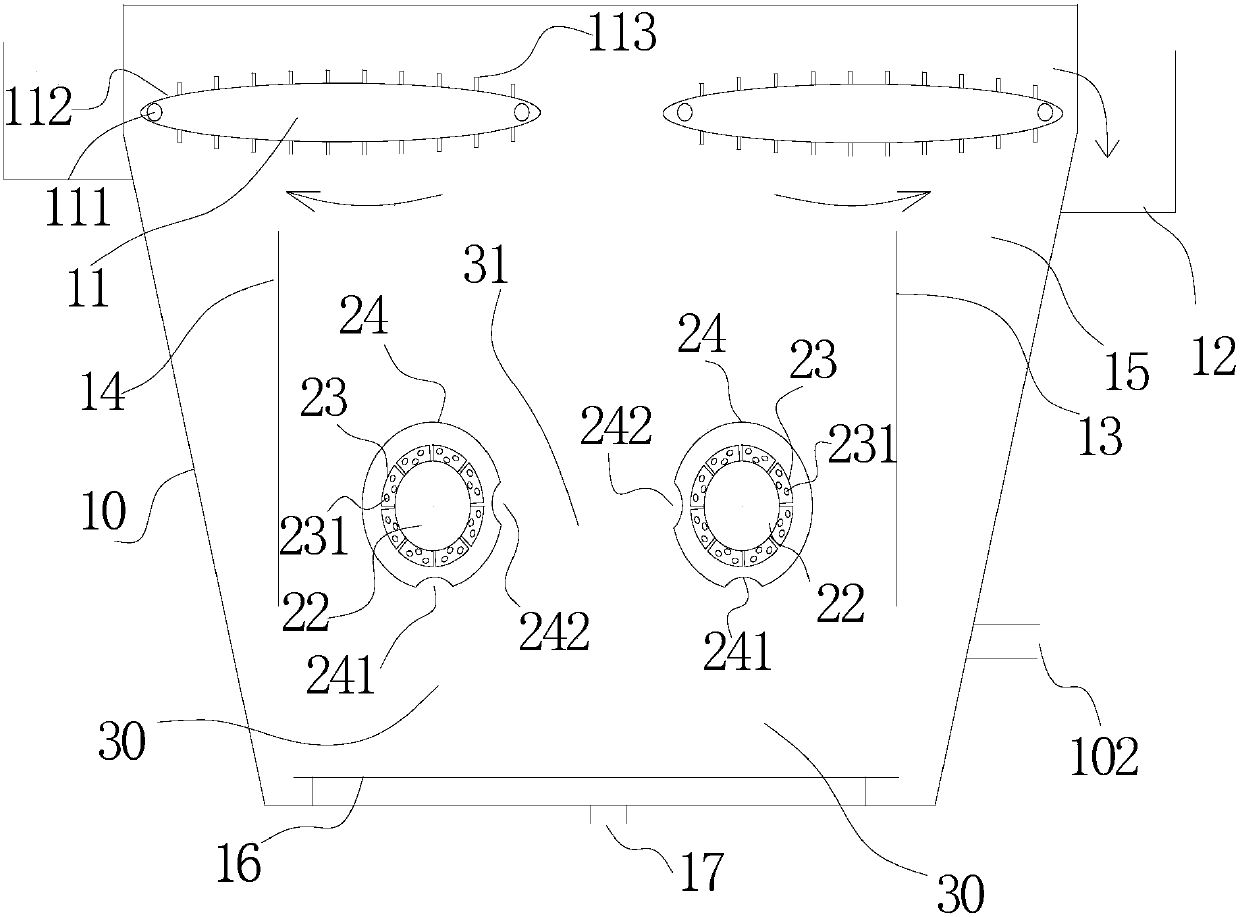

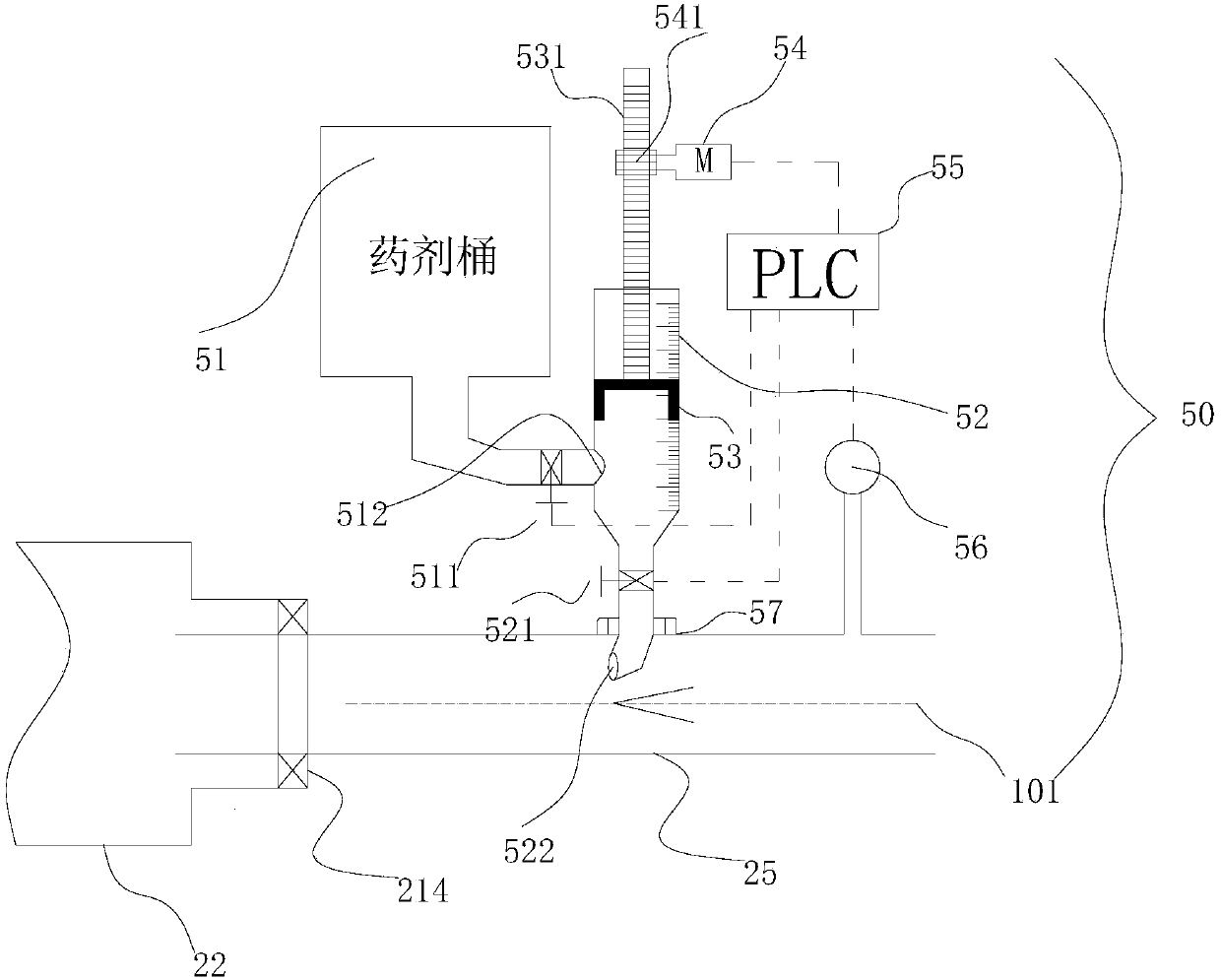

[0036] For ease of understanding, combined here Figure 1-8 , the specific embodiments of the present invention are further described as follows:

[0037] The specific components of the present invention are divided into several large modules, including: flotation cell (10), stirring mechanism (20), circulating bubble scraping mechanism (11), quantitative dosing system (50) and are described in detail one by one below:

[0038] 1. Stirring mechanism

[0039] its institutions such as figure 1 , Figure 4 As shown, the stirring mechanism (20) is the focus of the present invention; this example is shown with a pair of stirring mechanisms (20), that is: stirring mechanism one (201) and stirring mechanism two (202), and the stirring mechanism (20) is along the horizontal direction Arranged in parallel inside the flotation cell (10); stirring mechanism one (201) comprises a rotating cylinder (22), and the two ends of the rotating cylinder (22) are provided with bearing one (213) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com