Preparation method for chitosan natural polymer modified crude oil desalting demulsifier

A technology of natural polymer and demulsifier, applied in the direction of chemical dehydration/demulsification, etc., can solve the problems of weak binding ability and release of metal cations, achieving good safety in use, wide sources, and increasing the difficulty of demulsification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

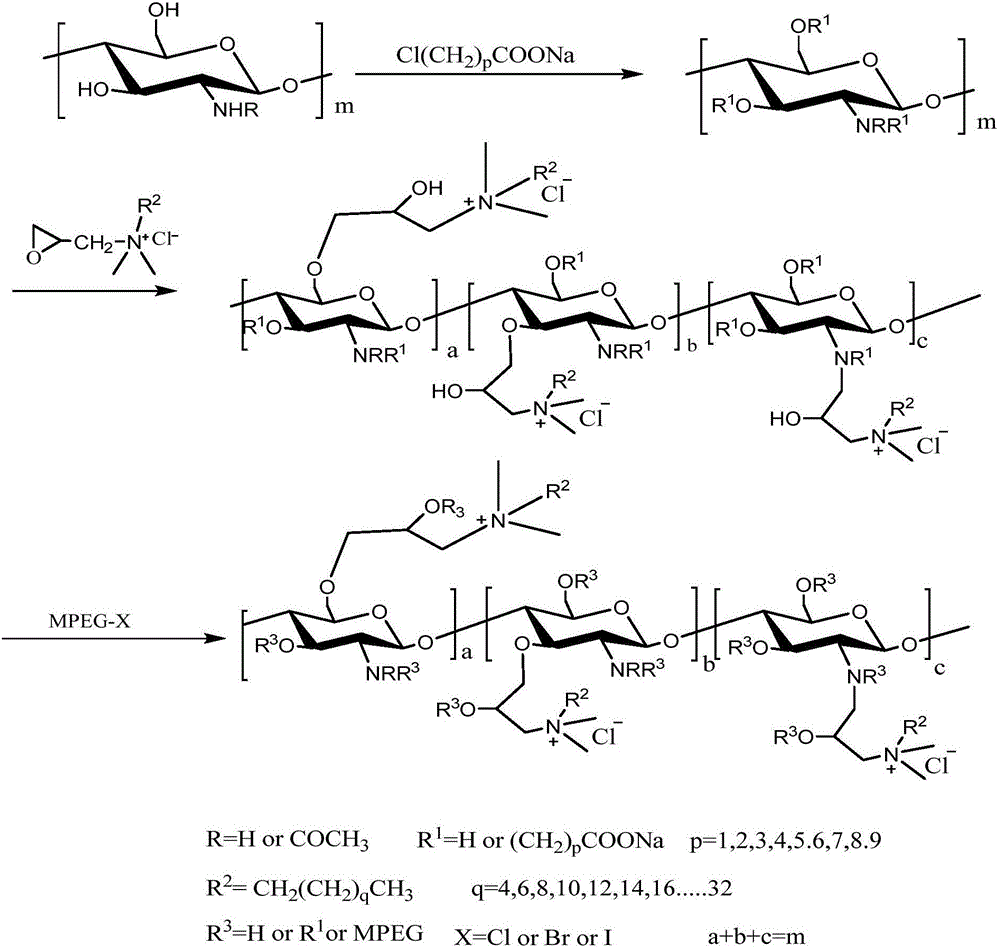

[0046] A preparation of chitosan natural macromolecular modified crude oil desalination demulsifier, specifically comprising the following steps:

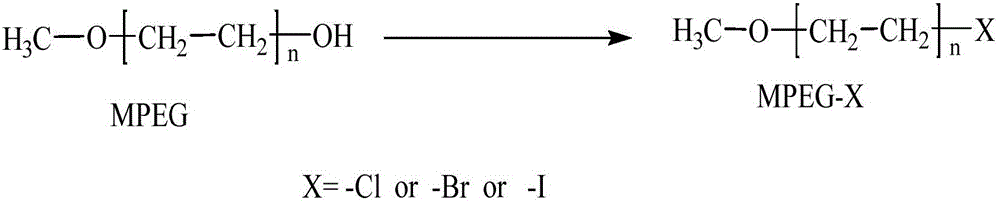

[0047] (1) Chlorination modification of terminal hydroxyl groups of polyethylene glycol monomethyl ether: Dissolve 1.75 g (5 mmol) of polyethylene glycol monomethyl ether (Mn=350) in 40 mL of 1,4-dioxane and freeze Stir in a water bath (0°C), add 0.79g (10mmol) of pyridine and 1.19g (10mmol) of thionyl chloride, and react under reflux at 70°C for 2h. The solvent was removed by distillation under reduced pressure, the residual solid was dissolved in dichloromethane, washed with water for 3 times, anhydrous sodium sulfate was added to remove water, and then filtered with suction, the filtrate was distilled under reduced pressure to obtain a solid, and freeze-dried to obtain chloropolyethylene glycol monomethyl ether ;

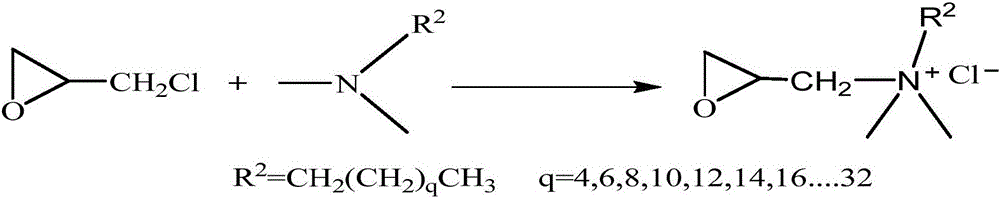

[0048] (2) Preparation of glycidyl dimethyl dodecyl ammonium chloride: add 2.13g of dodecyl dimethyl tertiary amin...

Embodiment 2

[0053] A preparation of chitosan natural macromolecular modified crude oil desalination demulsifier, specifically comprising the following steps:

[0054] (1) Bromination modification of terminal hydroxyl groups of polyethylene glycol monomethyl ether: Take 3.75 g (5 mmol) of polyethylene glycol monomethyl ether (Mn=750) and dissolve it in 40 mL of 1,4-dioxane, and freeze Stir in a water bath (2°C), add 1.18g (15mmol) of pyridine and 1.78g (15mmol) of thionyl bromide, and react under reflux at 70°C for 4h. The solvent was removed by distillation under reduced pressure, the residual solid was dissolved in dichloromethane, washed 3 times with water, anhydrous sodium sulfate was added to remove water, and then filtered with suction, the filtrate was evaporated under reduced pressure to obtain a solid, which was freeze-dried to obtain brominated polyethylene glycol mono methyl ether.

[0055] (2) Preparation of glycidyl dimethyltetradecyl ammonium chloride: add 2.41g tetradecyl d...

Embodiment 3

[0060] A preparation of chitosan natural macromolecular modified crude oil desalination demulsifier, specifically comprising the following steps:

[0061](1) Iodination modification of terminal hydroxyl groups of polyethylene glycol monomethyl ether: take 5 g (5 mmol) of polyethylene glycol monomethyl ether (Mn=1000) and dissolve it in 40 mL of toluene, and stir in an ice-water bath (5° C.) , Add 1.73g (7.5mmol) of silver oxide, 0.166g (1mmol) of potassium iodide and 1g (5mmol) of p-toluenesulfonyl chloride, and react at room temperature for 12h. The silver oxide was removed by filtration, the solvent was evaporated under reduced pressure, the remaining mixture was added into 30 mL of acetonitrile, the temperature was raised to 60° C., and stirring was continued for 2 h. The reaction solution was separated by column chromatography with the mobile phase of dichloromethane and methanol, and freeze-dried to obtain iodopolyethylene glycol monomethyl ether.

[0062] (2) Preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com