A viscosity-reducing coalescence device based on the principle of mechanical shear and swirl

A mechanical shearing and coalescing device technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of increasing the viscosity of the produced fluid, the degree of oil emulsification, and the difficulty of water treatment, etc. To achieve the effect of increasing emulsification degree, reducing impact and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

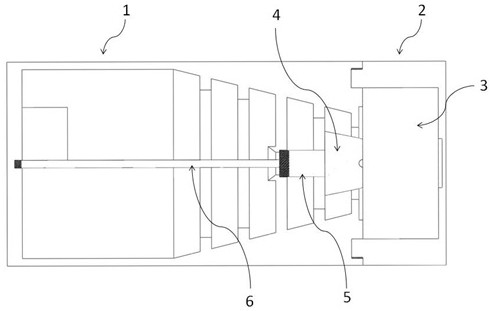

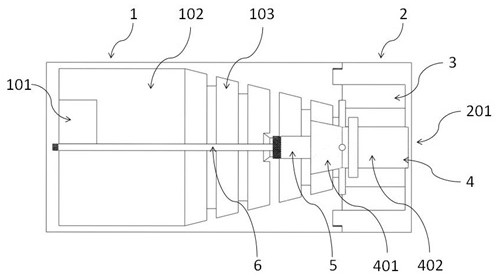

[0041] The present invention will be further explained below in conjunction with the drawings:

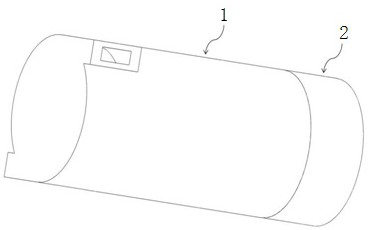

[0042] Combine Figure 1-Figure 16 As shown, this viscosity-reducing coalescence device based on the principle of mechanical shear and swirling flow is mainly divided into an upper working area surrounded by a viscosity-reducing coalescing outer cylinder 1 and a lower working area surrounded by a positioning sleeve 2. Cooperate with positioning booster 3, viscosity reducing coalescing sleeve 4, oil lead pipe 5 and lead rod 6 to realize viscosity reduction and coalescence. The swirling work space composed of the viscosity-reducing coalescing outer cylinder 1 and the internal components of the viscosity-reducing coalescing sleeve 4, etc., includes the surface of the lead rod and the lead pipe coated with lipophilic materials, as well as the viscosity-reducing shearing ladder 104 and increasing The design of the pressure ladder realizes the effect of viscosity reduction and coalescence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com