Preparation method of modified polyarylether (PAE) resin

A resin and modification technology, which is applied in the field of preparation of modified PAE resin, can solve the problems of not being able to meet the needs of high wet strength paper for moisturizing strength, and the PAE resin cannot be fully cured, so as to achieve enhanced moisturizing strength and dry strength. , the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

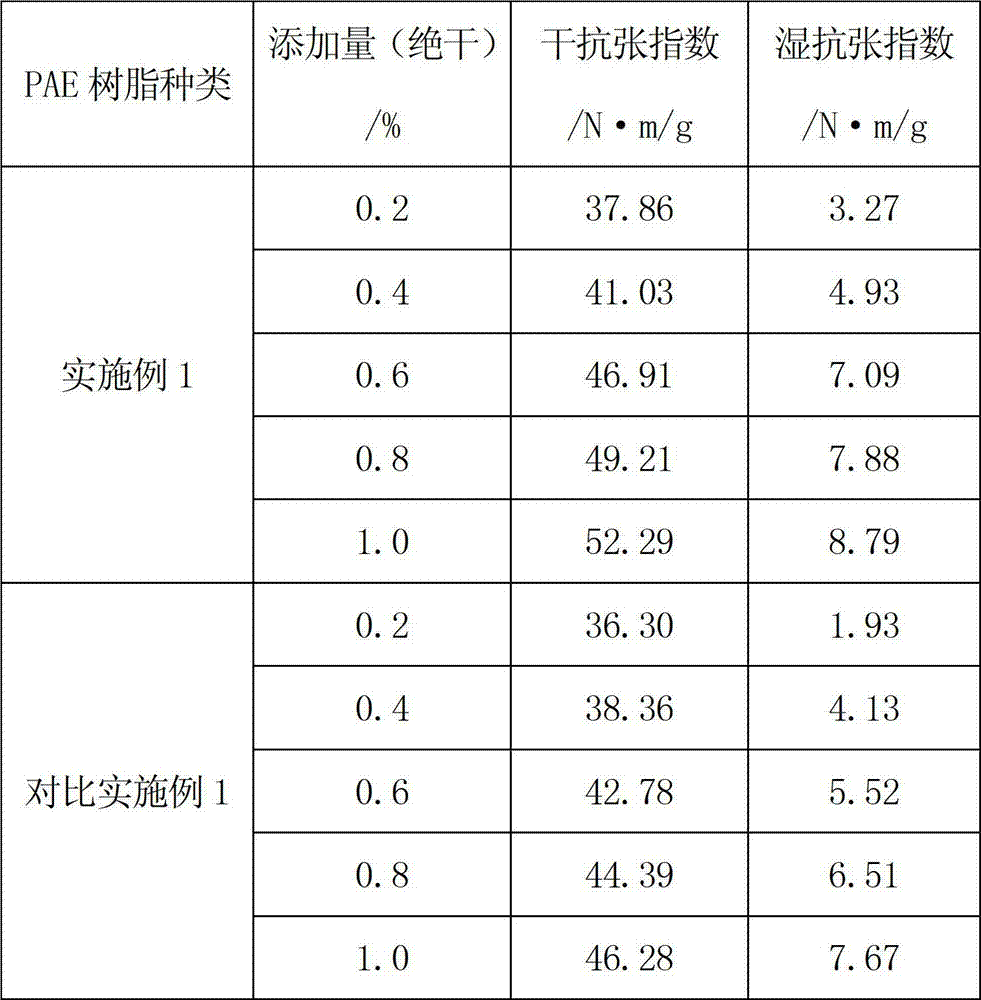

Examples

Embodiment 1

[0018] 1) Synthesis of polyamine prepolymer:

[0019] At 170°C, react diethylenetriamine and adipic acid under the action of p-toluenesulfonic acid catalyst for 4 hours to synthesize polyamine prepolymer. After the reaction, dilute with water to a solid content of 50%;

[0020] The molar ratio of the polyethylene polyamine, adipic acid and catalyst is 1:0.95:0.01;

[0021] 2) Epoxyalkylation reaction:

[0022] Adjust the solid content of the polyamine prepolymer to 25% and the pH value to 8, add the carboxyl modifier maleic anhydride, raise the temperature to 50°C, slowly add epichlorohydrin, raise the temperature to 70°C for 2 hours, and the reaction is over Finally, add hydrochloric acid, adjust the pH value to 4, terminate the reaction, add water to dilute to a solid content of 12.5%, and obtain the modified PAE resin;

[0023] The molar ratio of the polyamine prepolymer, carboxyl modifier, and epichlorohydrin is 1:0.1:1.2.

Embodiment 2

[0025] 1) Synthesis of polyamine prepolymer:

[0026] At 160°C, react triethylenetetramine and adipic acid under the action of p-toluenesulfonic acid catalyst for 6 hours to synthesize polyamine prepolymer. After the reaction, dilute with water to a solid content of 50%;

[0027] The molar ratio of the polyethylene polyamine, adipic acid and catalyst is 1:1:0.01;

[0028] 2) Epoxyalkylation reaction:

[0029] Adjust the solid content of the polyamine prepolymer to 20% and the pH value to 9, add the carboxyl modifier fumaric acid, raise the temperature to 55°C, slowly add epichlorohydrin, raise the temperature to 65°C and react for 3 hours, after the reaction, Add hydrochloric acid, adjust the pH value to 3, terminate the reaction, add water to dilute to a solid content of 12.5%, and obtain the modified PAE resin;

[0030] The molar ratio of the polyamine prepolymer, carboxyl modifier, and epichlorohydrin is 1:0.15:1.4.

Embodiment 3

[0032] 1) Synthesis of polyamine prepolymer:

[0033] At 180°C, react tetraethylenepentamine and succinic acid for 4 hours under the action of catalyst p-toluenesulfonic acid to synthesize polyamine prepolymer. After the reaction, dilute with water to a solid content of 50%;

[0034] The molar ratio of the polyethylene polyamine, succinic acid and catalyst is 1:0.9:0.01;

[0035] 2) Epoxyalkylation reaction:

[0036] Adjust the solid content of the polyamine prepolymer to 30% and the pH value to 8, add the carboxyl modifier maleic anhydride, raise the temperature to 30°C, slowly add epichlorohydrin, raise the temperature to 75°C for 1 hour, and the reaction is over Finally, add hydrochloric acid, adjust the pH value to 4, terminate the reaction, add water to dilute to a solid content of 12.5%, and obtain the modified PAE resin;

[0037] The molar ratio of the polyamine prepolymer, carboxyl modifier, and epichlorohydrin is 1:0.1:1.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com