Clay-resistant polycarboxylate water reducer and preparation method thereof

A technology of polycarboxylate and water reducer, which is applied in the field of concrete water reducer preparation, can solve the problems of affecting the normal hydration of aluminosilicate, limited impact on slump retention, and lack of pertinence, so as to achieve good control of concrete Slump loss performance, guaranteed strength and durability, and increased firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

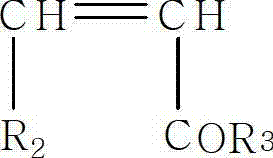

Method used

Image

Examples

preparation example Construction

[0033] The embodiment of the present invention also provides a preparation method for the above clay-resistant polycarboxylate water reducer, including:

[0034] Take each component according to the formula of the above-mentioned anti-clay type polycarboxylate water reducer;

[0035] The components are polymerized in an aqueous solution using a redox initiation system at a temperature of 10-70°C (preferably at a temperature of 25-40°C), and then neutralized by a neutralizing agent after the polymerization. The polymer is the clay-resistant polycarboxylate water reducer.

[0036] In the above method, the oxidant in the redox initiation system used is one of hydroperoxide, persulfate or their mixture, and the amount of the oxidant is 0.2% to 0.2% of the total weight of the monomers in each component. 2.0%;

[0037] The reducing agent in the redox initiation system used is one of low-valent compounds of sulfur, L-ascorbic acid or a mixture thereof, and the amount of the reducin...

Embodiment 1

[0058] This example provides a clay-resistant polycarboxylate water-reducer. The amounts of the following components used to prepare the water-reducer are all by weight. When equipped with a stirrer, a thermometer, a dropping device, Add 160 parts by weight of methacryl polyethylene glycol 1000, 180 parts by weight of methacryl polyethylene glycol 2400, 400 parts by weight of 1000 weight average molecular weight in the four-necked glass flask of reflux condenser and nitrogen protection device After heating up to 35°C, add 20.5 parts by weight of methacrylic acid, 17.5 parts by weight of methyl acrylate, and 10.5 parts by weight of methacrylic acid to the reaction vessel dropwise within 2 to 3 hours. A monomer solution of sodium sulfonate, 7.5 parts by weight of 2-methacrylamide-3-propenesulfonic acid and 100 parts by weight of deionized water is added dropwise and mixed with 2.5 parts by weight of mercaptoacetic acid and a mass concentration of 60 parts by weight 2% L-ascorbic...

Embodiment 2

[0060] This example provides a clay-resistant polycarboxylate water-reducer. The amounts of the following components used to prepare the water-reducer are all by weight. When equipped with a stirrer, a thermometer, a dropping device, In the four-necked glass flask of reflux condenser, nitrogen protection device, add the deionized water of the methylbutenyl polyethylene glycol 1000 of 135 parts by weight, the methylbutenyl polyethylene glycol 2000 of 205 parts by weight, 400 parts by weight After the temperature was raised to 50°C, 17.5 parts by weight of methacrylic acid, 20.5 parts by weight of butyl acrylate, 17.5 parts by weight of sodium methacrylic acid, 10.5 parts by weight of sodium methacrylic acid were added dropwise to the reaction vessel within 2 to 3 hours. A monomer solution of 2-methacrylamide-3-propenesulfonic acid and 100 parts by weight of deionized water was added dropwise and mixed with 2.5 parts by weight of mercaptopropionic acid and 60 parts by weight of L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com