Salt- and temperature-resistant emulsification viscosity reducer for heavy oil

A technology of emulsification, viscosity reduction and temperature resistance, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve problems such as high back pressure of surface pipelines, difficulties in safe production of heavy oil wells, and low content of straight-chain hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

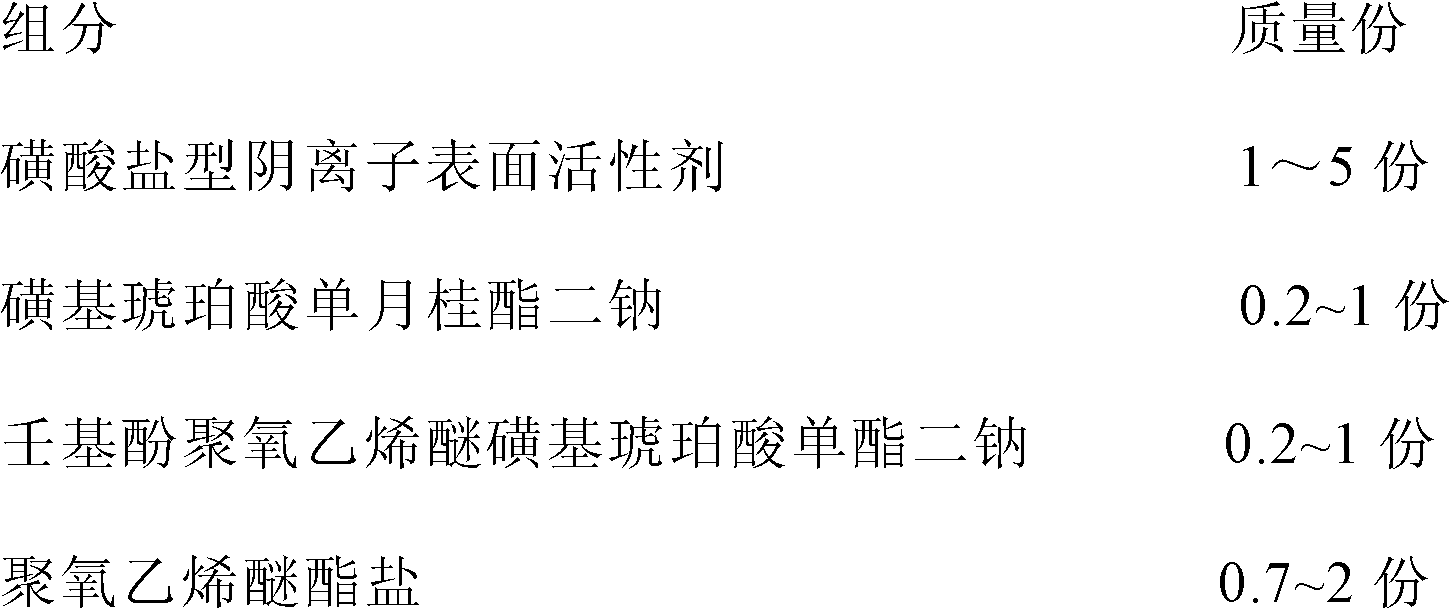

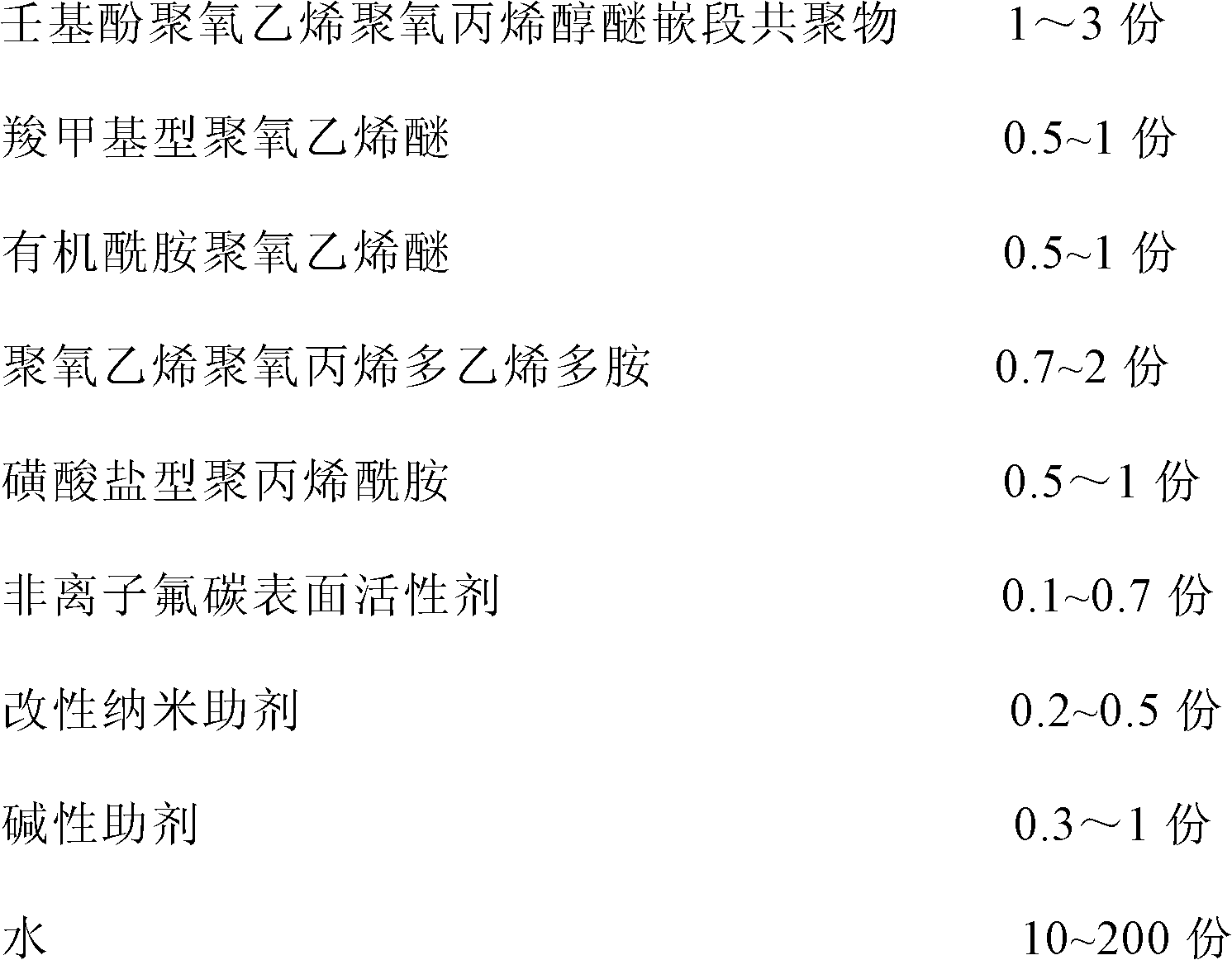

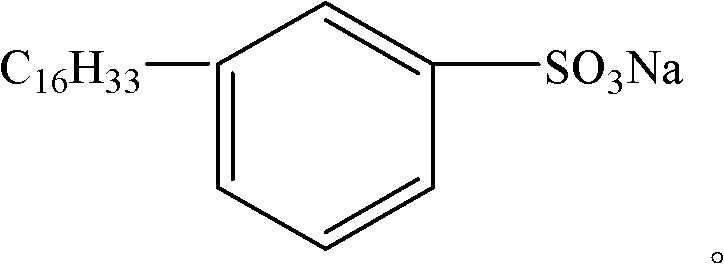

[0086] Embodiment 1: salt-resistant and temperature-resistant viscous oil emulsifying viscosity reducer, parts by mass of each component:

[0087]

[0088]

[0089] (1) Sodium dodecylbenzenesulfonate, disodium monolauryl sulfosuccinate and disodium nonylphenol polyoxyethylene ether sulfosuccinate monoester are prepared into an aqueous solution at 20°C under normal pressure stirring conditions, Slowly add lauryl alcohol polyoxyethylene (3) ether sodium sulfate, nonylphenol polyoxyethylene polyoxypropylene ether, methyl glucoside sesquistearate polyoxyethylene (20) ether, lauric acid monoethanolamide polyoxyethylene (3) ether and tetraethylenepentamine polyoxyethylene polyoxypropylene ether to obtain an aqueous solution of the main agent.

[0090] (2) Spray 2-acrylamide-2-methylpropanesulfonic acid, nonionic fluorocarbon surfactant FN-2 and modified nano-auxiliary ZnO (10nm) on the water surface at 20°C under normal pressure stirring conditions After continuous stirring f...

Embodiment 2

[0094] Embodiment 2: Anti-salt and temperature-resistant viscous oil emulsifying agent, parts by mass of each component:

[0095]

[0096] (1) Prepare sodium lignosulfonate, disodium monolauryl sulfosuccinate and disodium nonylphenol polyoxyethylene ether sulfosuccinate monoester into an aqueous solution at 50°C with normal pressure stirring, then slowly add Alkylphenol polyoxyethylene (10) ether sodium sulfate, nonylphenol polyoxyethylene (7) polyoxypropylene (2) ether, methyl glucoside polyoxyethylene (10) ether, polyoxyethylene stearamide and polyoxyethylene stearamide Ethylene polyamine polyoxypropylene polyoxyethylene ether to obtain the aqueous solution of the main agent.

[0097] (2) Spray sulfomethylated polyacrylamide, non-ionic fluorocarbon surfactant FN-3, and modified nano-auxiliary ZnO (200nm) on the water surface under normal pressure stirring conditions at 50°C, continue stirring for 30 minutes and slowly Add polyethylene glycol to obtain an aqueous solution...

Embodiment 3

[0101] Embodiment 3: salt-resistant and temperature-resistant viscous oil emulsifying viscosity reducer, parts by mass of each component:

[0102]

[0103] (1) Prepare sodium dodecyl diphenyl ether disulfonate, disodium monolauryl sulfosuccinate and disodium nonylphenol polyoxyethylene ether sulfosuccinate monoester at 60°C under normal pressure stirring conditions into an aqueous solution, and then slowly add nonylphenol polyoxyethylene ether sodium sulfate, nonylphenol polyoxyethylene polyoxypropylene ether, methyl glucoside polyoxyethylene (20) ether, polyoxyethylene lauric acid diethanolamide and polyethylene Polyamine polyoxyethylene polyoxypropylene ether to obtain the aqueous solution of the main agent.

[0104] (2) Spray polyacrylamide sulfonate copolymer, non-ionic fluorocarbon surfactant FN-3 and modified nano-auxiliary CaO (100nm) on the water surface under normal pressure stirring conditions at 60°C, and continue stirring for 60min Then slowly add ethylene glyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com