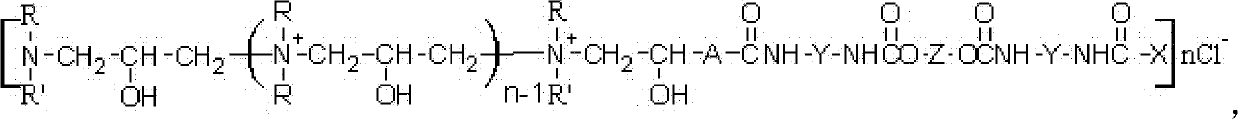

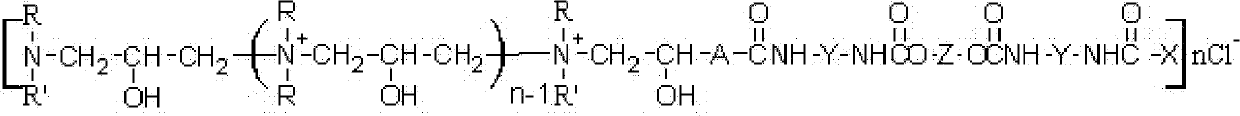

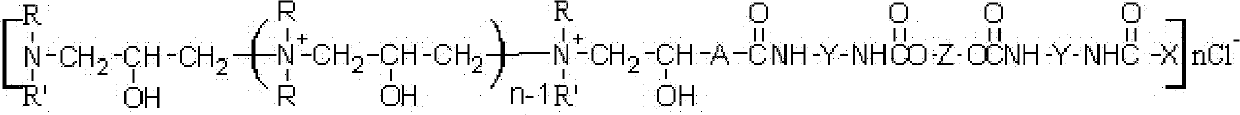

Waterborne polyurethane graft-modified polyamine color fixing agent and preparation method thereof

A water-based polyurethane, graft-modified technology, applied in dyeing, textile and papermaking, etc., can solve the problems of poor color-fixing effect of color-fixing agents and environmental pollution, and improve the color fastness to washing and wet rubbing. , Improve the color fastness to soaping, improve the color fastness to wet rubbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] (1) Preparation of polyamine polymer:

[0064] By mass percentage, 13.23% N-ethylethylamine (diethylamine) was added in the reactor, then 52.95% epichlorohydrin was added dropwise thereto, and the temperature was kept at 40°C for 3 hours to react, and then to the reaction Add 0.99% tetraethylenepentamine into the container, gradually raise the temperature to 80°C, return to room temperature after reflux reaction for 4 hours, and seal it for later use.

[0065] (2) Preparation of polyurethane prepolymer

[0066] Distill 5.96% PEG600 under reduced pressure at 100°C for 2 hours, add 13.24% acetone after cooling down to 55°C, and seal it for future use. Add 4.90% IPDI to the dry reactor, fill it with nitrogen for protection, add polyether diol drop by drop through the dropping funnel, add 0.132% stannous octoate, control the temperature at 55°C, and keep the reaction for 2.5 hours to obtain Polyurethane prepolymers.

[0067] (3) Chain extension reaction

[0068] Cool th...

Embodiment 2

[0074] (1) Preparation of polyamine polymer:

[0075] By mass percentage, add 2.51% part N-methylmethylamine (dimethylamine) in the reactor, dropwise thereinto the epichlorohydrin of 3.77% then, keep the temperature at 20 ℃ and react for 5 hours, then add Add 0.63% triethylenetetramine into the reactor, gradually raise the temperature to 50° C., return to room temperature after 5 hours of reflux reaction, and seal it for future use.

[0076] (2) Preparation of polyurethane prepolymer

[0077] Distill the mixture of 22.61% PEG600 and 18.84% PPG1500 under reduced pressure at 100°C for 2 hours, add 6.28% methyl ethyl ketone after cooling down to 50°C, and seal it for future use. Add 26.38% MDI to the dry reactor, fill it with nitrogen for protection, drop the mixture of the above two polyether diols into the dropping funnel, add 0.025% DBTDL, control the temperature at 65°C, and keep the reaction for 2 hours , to obtain a polyurethane prepolymer.

[0078] (3) Chain extension r...

Embodiment 3

[0085] (1) Preparation of polyamine polymer:

[0086] According to the mass percentage, add 32.19% trimethylamine into the reactor, then dropwise add 48.29% epichlorohydrin therein, keep the temperature at 60°C for 1.5 hours, then add 1.61% diethylenetri For amine, the temperature was gradually raised to 80°C, the reaction was refluxed for 2 hours, and then the temperature was lowered to room temperature, and sealed for later use.

[0087] (2) Preparation of polyurethane prepolymer

[0088] Distill 2.70% PEG600 under reduced pressure at 100°C for 2 hours, add 3.22% acetone after cooling down to 50°C, and seal it for future use. Add 2.00% IPDI to the dry reactor, fill it with nitrogen for protection, add polyether diol dropwise into the dropping funnel, add 0.013% of stannous octoate, control the temperature at 50°C, and keep the temperature for 2 hours to prepare Obtain polyurethane prepolymer.

[0089] (3) Chain extension reaction

[0090] Cool the polyurethane prepolymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com