A kind of suede color fixing agent and its preparation method and application

A color-fixing agent and a technology for suede leather, applied in the field of suede-color-fixing agent and its preparation, can solve the problem that the color-fixing agent contains toxic solvents, the PU leather has poor dry rubbing fastness and wet rubbing fastness, and poor stability. and other problems, to achieve the effect of obvious color fixing effect, improving color fastness and excellent friction resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

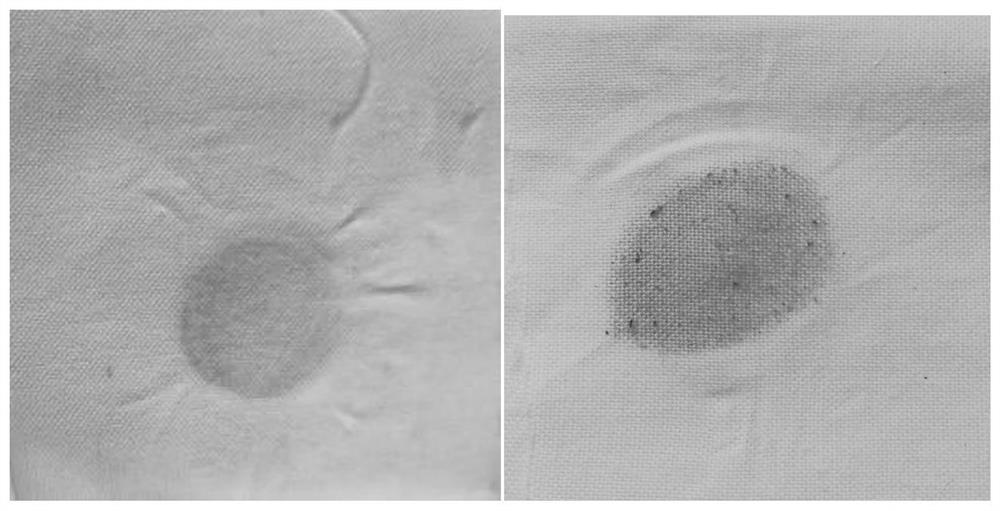

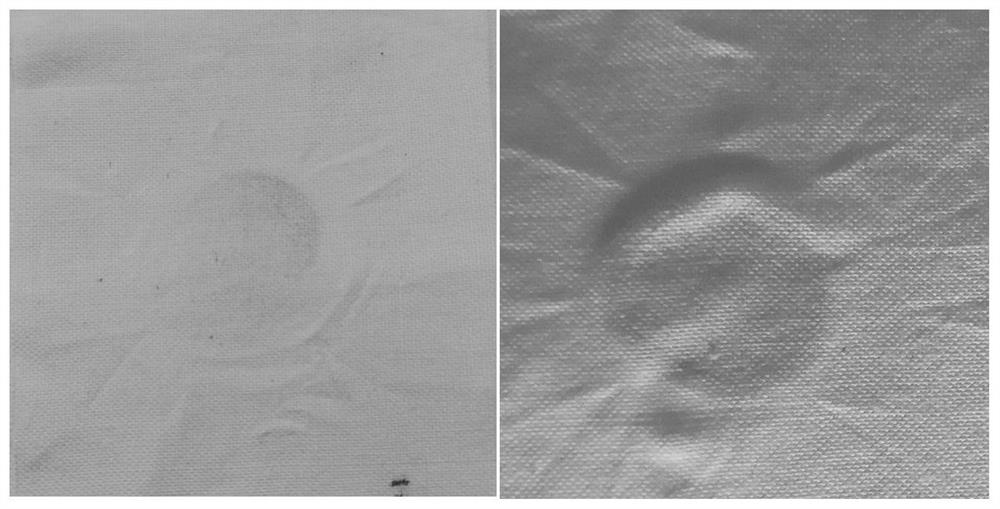

Image

Examples

Embodiment 1

[0040] (1) Prepolymerization reaction: place 2.6g of toluene diisocyanate and 20g of polytetrahydrofuran diol on water-absorbing molecular sieves for dehydration and drying for 24 hours, put them into a three-necked flask after dehydration, mix well, and heat up to 75°C for 3 hours;

[0041] (2) Chain extension reaction: Add 0.34 g of dimethylolpropionic acid, keep stirring at 75° C. for 1 h.

[0042] Then, 0.21 g of diethylene glycol was added to the reaction system, and the reaction temperature was lowered from 75° C. to 35° C. and the reaction was stirred to obtain a polyurethane prepolymer;

[0043] (3) Neutralization and ionization: at a temperature of 35 to 50°C, add 0.25 g of triethylamine to the polyurethane prepolymer obtained in step (2) and stir for 15 minutes to obtain an anionic polyurethane prepolymer;

[0044] (4) Crosslinking reaction: after neutralization and ionization, lower the temperature to room temperature, add 0.44g of silicon-containing crosslinking ag...

Embodiment 2

[0047] (1) Prepolymerization reaction: place 4.2g of hexamethylene diisocyanate and 10g of polyethylene glycol on water-absorbing molecular sieves for dehydration and drying for 24 hours, put them into a three-necked flask after dehydration, mix well, and heat up to 80°C for 2 hours;

[0048] (2) Chain extension reaction: Add 0.28 g of dimethylol butyric acid, keep stirring at 80° C. for 1 h.

[0049] Then, 1.25g of diethylene glycol was added to the reaction system, and the reaction temperature was lowered from 80°C to 40°C and stirred for reaction to obtain a polyurethane prepolymer;

[0050](3) Neutralization and ionization: add 0.19g triethylamine to the polyurethane prepolymer obtained in step (2) and stir and neutralize for 20min to obtain anionic polyurethane prepolymer;

[0051] (4) Cross-linking reaction: neutralization and ionization are completed, the temperature is lowered to room temperature, and 0.11 g of aziridine is added to stir and react for 1 hour to obtain ...

Embodiment 3

[0054] (1) Prepolymerization reaction: 6.67g of isophorone diisocyanate and 20.15g of polyethylene adipate diol were placed in a water-absorbing molecular sieve for dehydration and drying for 24 hours, and after dehydration, they were put into a three-necked flask, and after mixing evenly, Raise the temperature to 85°C for 1.5h;

[0055] (2) Chain extension reaction: add 0.67 g of dimethylolpropionic acid, keep stirring at 85° C. for 1 h.

[0056] Then, 1.5 g of diethylene glycol was added to the reaction system, and the reaction temperature was lowered from 85° C. to 50° C. and the reaction was stirred to obtain a polyurethane prepolymer;

[0057] (3) Neutralization and ionization: add 0.5g triethylamine to the polyurethane prepolymer obtained in step (2) and stir and neutralize for 10min to obtain anionic polyurethane prepolymer;

[0058] (4) Cross-linking reaction: neutralization and ionization are completed, the temperature is lowered to room temperature, 0.14 g of epichl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com