A steel chimney inner wall anti-corrosion structure and its construction method

A construction method and chimney technology, which are applied in combustion methods, building components, building structures, etc., can solve the problems of easy penetration of foamed glass brick lining, high cost of titanium-steel composite panels, poor acid and corrosion resistance, etc., and achieve light weight. , Improve the bonding force, the effect of good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

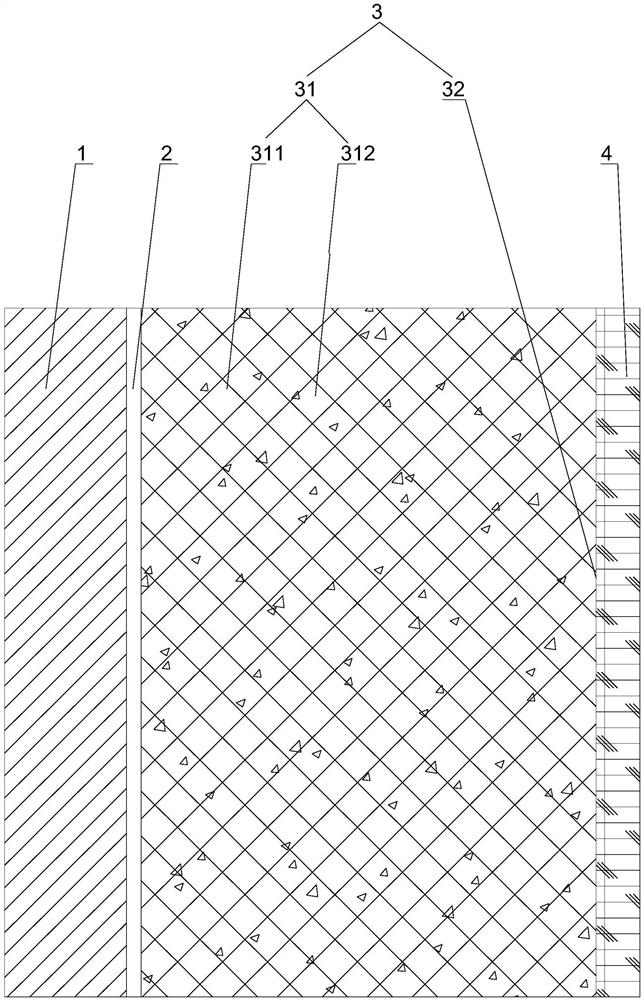

[0030] An anti-corrosion structure for the inner wall of a steel chimney, which sequentially includes an adhesive layer 2 coated on the inner wall of a steel chimney 1, a shrinkage structure layer 3 adhered to the adhesive layer 2, and a shrinkage layer coated on the surface of the shrinkage structure layer 3 from outside to inside. top coat 4;

[0031] The adhesive layer 2 is an epoxy adhesive, and the thickness of the adhesive layer 2 is 3mm;

[0032] The shrinkage structure layer 3 includes a honeycomb network 311 layer 31 and a sealing layer 32, and the honeycomb network 311 layer 31 is a honeycomb network 311 filled with a blend 312 of epoxy resin powder, polyimide powder and liquid phenolic resin , the mixing ratio of the blend 312 is epoxy resin powder: polyimide powder: liquid phenolic resin is 3:3:4 (weight), the thickness of the honeycomb network 311 is 75mm, the sealing layer 32 Coated on the surface of the layer 31 of the honeycomb network 311, the sealing layer 3...

Embodiment 2

[0043] An anti-corrosion structure for the inner wall of a steel chimney, which sequentially includes an adhesive layer 2 coated on the inner wall of a steel chimney 1, a shrinkage structure layer 3 adhered to the adhesive layer 2, and a shrinkage layer coated on the surface of the shrinkage structure layer 3 from outside to inside. top coat 4;

[0044] The adhesive layer 2 is an epoxy adhesive, and the thickness of the adhesive layer 2 is 2mm;

[0045]The shrinkage structure layer 3 includes a honeycomb network 311 layer 31 and a sealing layer 32, and the honeycomb network 311 layer 31 is a honeycomb network 311 filled with a blend 312 of epoxy resin powder, polyimide powder and liquid phenolic resin , the mixing ratio of the blend 312 is epoxy resin powder: polyimide powder: liquid phenolic resin is 1:5:4 (by weight), the thickness of the honeycomb network 311 is 60mm, the sealing layer 32 Coated on the surface of the layer 31 of the honeycomb network 311, the sealing layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com